Polymers, the backbone of modern materials science, present a world of diversity with their vast array of properties and applications. Among these, polyacrylates and polyesters stand out due to their unique characteristics and widespread use in various industries. Both these materials play pivotal roles, from enhancing the durability of paints and adhesives to revolutionizing the textile industry with their application in fabrics.

Polyacrylates and polyesters, while often mentioned in the same breath, are distinct in their chemical structures, production processes, and applications. Polyacrylates are known for their excellent elasticity and resistance to sunlight, making them ideal for use in paints, adhesives, and sealants. Polyesters, on the other hand, are celebrated for their strength, durability, and resistance to wrinkles and shrinking, making them a favorite in the textile industry and beyond.

This discussion extends beyond mere definitions to a comprehensive comparison of their properties, environmental impact, and cost-effectiveness. By exploring the nuances of their chemical compositions, applications, and the innovative trends shaping their future, we delve into the heart of what sets polyacrylates and polyesters apart, providing a lens through which to view their contributions to modern materials science.

Polyacrylates Overview

Definition and Properties

Polyacrylates are a type of polymer made from acrylic acid or its derivatives. This category of materials is known for its excellent elasticity, transparency, and resistance to sunlight, water, and certain chemicals. Polyacrylates are unique because of their flexible molecular structure, which allows them to stretch and return to their original shape without damage.

Common Uses

Polyacrylates serve a broad range of applications due to their versatile properties. They are commonly found in:

- Paints and coatings: Provides a durable, protective, and glossy finish.

- Adhesives and sealants: Offers strong bonding and sealing capabilities.

- Hygiene products: Used in superabsorbent polymers for diapers and sanitary products.

Polyesters Overview

Definition and Properties

Polyesters are a group of polymers formed through the reaction between a dicarboxylic acid and a diol. They are renowned for their strength, durability, and resistance to many environmental factors, including UV light and moisture. Polyesters can be either thermoplastic or thermoset, allowing for a wide range of applications from fibers and films to rigid, high-strength materials.

Common Uses

The versatility of polyesters makes them suitable for numerous applications, notably in:

- Textile industry: Fabric for clothing, due to its wrinkle resistance and durability.

- Packaging: Bottles, films, and foams for their clarity and stability.

- Automotive parts: Components that require lightweight and high-strength materials.

Chemical Structure

Polyacrylates Composition

Polyacrylates are composed of long chains of acrylate monomers. These monomers can be visualized as beads on a string, where each bead represents an acrylate unit. The flexibility and absorbency of polyacrylates are attributed to the polarity of the acrylate group, allowing them to interact with water and other substances at a molecular level.

Polyesters Composition

Polyesters consist of ester groups in their main chain. The formation of polyester involves the esterification reaction between acids and alcohols. This chemical structure contributes to polyesters’ rigidity and resilience, enabling them to withstand mechanical stress and environmental factors.

Comparison of Structural Differences

The key difference between polyacrylates and polyesters lies in their functional groups: acrylate for polyacrylates and ester for polyesters. These structural variations result in distinct properties; polyacrylates excel in flexibility and absorbency, whereas polyesters stand out in strength and thermal stability.

Production Process

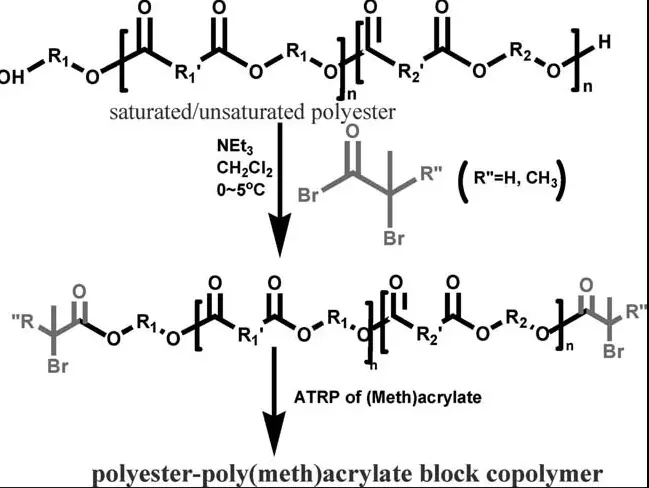

Polyacrylates Synthesis

The production of polyacrylates typically involves free-radical polymerization, where acrylate monomers are linked together in the presence of a catalyst. The process can be adjusted to control the polymer’s molecular weight, impacting its properties:

- Initiation: A catalyst triggers the reaction.

- Propagation: Monomers add to the growing chain.

- Termination: The reaction is stopped at the desired length.

Polyesters Synthesis

Polyesters are synthesized through a process known as condensation polymerization or esterification. This involves the reaction between a dicarboxylic acid and a diol, releasing water as a by-product:

- Esterification: Acid and alcohol react to form the ester bond.

- Polycondensation: Repeating units link to form long chains.

- Cooling and solidifying: The polyester is formed and prepared for further processing.

Key Differences in Production Methods

The synthesis of polyacrylates and polyesters highlights their distinct chemical reactions—free-radical polymerization for polyacrylates and condensation polymerization for polyesters. These differences in production not only influence their properties but also their applications and environmental impact.

Physical Properties

Durability and Resistance

Polyacrylates are praised for their elasticity and resistance to UV light and moisture, making them ideal for outdoor applications. Polyesters, with their inherent strength and durability, are suited for applications requiring long-term wear and tear resistance.

Thermal Properties

While both materials have good thermal properties, polyesters generally offer better heat resistance and thermal stability than polyacrylates. This makes polyesters a preferred choice for applications exposed to high temperatures.

Environmental Resistance

Polyacrylates and polyesters both exhibit resistance to various environmental factors. However, polyesters tend to have a higher resistance to chemicals and abrasion, which is crucial for textiles and industrial components.

Applications

Polyacrylates Applications

Industrial Uses

- Coatings and paints: Protects surfaces from weathering and UV damage.

- Medical devices: Used in hydrogels for wound dressings due to their absorbency and biocompatibility.

Everyday Products

- Hygiene products: Superabsorbent polymers in diapers absorb and retain large amounts of liquid.

- Adhesives: Strong, flexible bonds for various materials.

Polyesters Applications

Textile Industry

- Clothing: Resistant to shrinking, stretching, and wrinkles.

- Home furnishings: Durable fabrics for upholstery, curtains, and bedding.

Engineering Plastics

- Automotive parts: Lightweight and strong components reduce vehicle weight.

- Electrical insulation: Good thermal stability and electrical insulation properties.

Environmental Impact

Biodegradability of Polyacrylates

Polyacrylates, with their complex molecular structure, present a challenge to biodegradation processes. Their resistance to breaking down in natural environments contributes to landfill volume and potentially, when not managed properly, to plastic pollution. Research into enhancing the biodegradability of polyacrylates focuses on modifying the polymer structure or incorporating biodegradable segments to facilitate easier breakdown.

Biodegradability of Polyesters

The biodegradability of polyesters varies significantly with their chemical composition. Traditional petroleum-based polyesters are notoriously resistant to biodegradation, similar to other synthetic polymers. However, biobased polyesters, such as polylactic acid (PLA), offer a more environmentally friendly alternative, showcasing greater biodegradability under industrial composting conditions.

Recycling and Sustainability Efforts

Polyacrylates

- Chemical Recycling: Developing methods to break down polyacrylates to their monomers for repolymerization.

- Design for Degradability: Research into polyacrylates that degrade under specific conditions, reducing environmental impact.

Polyesters

- Mechanical Recycling: Polyester items, particularly PET bottles, are widely recycled, turning used products into new items.

- Chemical Recycling: Breaking down polyesters to their basic components to create new polymers, though less common than mechanical recycling due to complexity.

Cost Comparison

Manufacturing Costs

The production cost of polyacrylates and polyesters is influenced by several factors including the price of raw materials, energy requirements of the synthesis process, and the scale of production. Polyacrylates generally require more complex catalysts and conditions for polymerization, which can increase costs. Polyesters, especially PET, benefit from established, large-scale production processes that can reduce per-unit costs.

Market Prices

Market prices for polyacrylates and polyesters fluctuate based on demand, availability of raw materials, and production technology advancements. Polyesters, used extensively in textiles and packaging, often have a lower price point due to larger production volumes and recycling capabilities. Polyacrylates, with specialized applications, may command higher prices.

Factors Affecting Costs

- Raw Material Availability: Fluctuations in the availability and price of petroleum, a key raw material for both polymers, significantly impact costs.

- Technological Advancements: Innovations in production technology can reduce energy consumption and raw material waste, lowering costs.

- Regulatory Environment: Environmental regulations can increase production costs by requiring cleaner, but more expensive, manufacturing processes.

Advantages and Limitations

Polyacrylates

Benefits in Specific Applications

Polyacrylates excel in applications requiring flexibility, transparency, and resistance to environmental factors. Their use in coatings, adhesives, and superabsorbent products highlights their unique properties.

Limitations and Challenges

The main limitations include cost, particularly for high-performance grades, and environmental impact, given their resistance to degradation.

Polyesters

Strengths and Advantages

Polyesters offer durability, resistance to chemicals and UV light, and ease of recycling, making them suitable for a wide range of applications from textiles to automotive parts.

Drawbacks

Drawbacks include the environmental concerns associated with their petroleum-based origins and challenges in biodegradability, especially for non-recycled materials.

Future Trends

Innovations in Polyacrylate Applications

Emerging trends in polyacrylate technology focus on enhancing biodegradability and expanding functionality. New formulations aim to combine the inherent properties of polyacrylates with novel features, such as improved mechanical strength or electrical conductivity, opening up new application areas.

Advances in Polyester Technology

Polyester technology continues to evolve, with significant research aimed at reducing environmental impact. This includes developing bio-based polyesters, improving recycling methods, and creating polyesters with enhanced properties such as higher thermal stability or reduced moisture absorption.

Potential for New Blends and Composites

The future of both polyacrylates and polyesters may lie in the development of blends and composites that leverage the strengths of both materials. By combining polyacrylates’ flexibility and polyesters’ strength, new materials with tailored properties for specific applications could be developed, offering solutions to current limitations and opening up new technological possibilities.

Frequently Asked Questions

What are polyacrylates used for?

Polyacrylates find their primary applications in products requiring flexibility and durability. They are extensively used in the manufacture of paints, adhesives, and sealants due to their exceptional elasticity and resistance to sunlight and water. Their ability to form films makes them indispensable in coatings and diapers, showcasing their versatility across various industries.

How are polyesters environmentally impactful?

Polyesters, particularly when derived from petroleum, pose significant environmental challenges, including non-biodegradability and contributions to microplastic pollution. However, strides in recycling technologies and the development of biodegradable polyester variants are beginning to mitigate these impacts. Efforts to increase polyester recycling rates and advancements in bio-based polyesters are promising steps towards reducing the environmental footprint of polyesters.

Can polyacrylates be recycled?

Recycling of polyacrylates is more challenging than with some other polymers due to their chemical structure and the cross-linking that often occurs in their applications. However, research into chemical recycling methods is ongoing, aiming to break down polyacrylates into their monomers for reuse. These efforts are part of a broader push to improve the sustainability of materials used in industry.

What distinguishes polyesters from polyacrylates?

The fundamental distinction between polyesters and polyacrylates lies in their chemical structures and resultant properties. Polyesters are characterized by their ester functional groups, contributing to their strength, durability, and application in textiles. Polyacrylates, with their acrylate groups, offer superior elasticity and resistance to environmental factors, making them ideal for use in coatings and adhesives.

Conclusion

The journey through the world of polyacrylates and polyesters reveals a landscape rich with innovation, challenges, and opportunities. These materials, with their distinct properties and applications, underscore the versatility and ingenuity inherent in polymer science. As we explore their differences, we not only gain insights into their unique contributions to our daily lives and industries but also appreciate the ongoing efforts to enhance their environmental sustainability.

In the realm of materials science, polyacrylates and polyesters represent two pivotal chapters in the ongoing story of human ingenuity and its relationship with the world. By understanding these materials better, we pave the way for smarter, more sustainable choices in their production, use, and disposal, aligning technological advancement with environmental stewardship.