Desiccants are critical components used across various industries to control humidity and prevent degradation of products. Two of the most widely utilized types are molecular sieves and silica gel, each with unique characteristics and applications. While they may seem similar at first glance, their differences are substantial when examined closely.

Molecular sieves and silica gel are both desiccants, but they function differently due to their distinct chemical compositions. Molecular sieves, made from synthetic zeolites, are known for their uniform pore sizes, which allow for selective adsorption of particles. In contrast, silica gel, made from silicon dioxide, absorbs moisture through its irregularly shaped pores, making it suitable for a broader range of applications.

The significance of choosing the right desiccant cannot be overstated, as it directly impacts the efficiency and effectiveness of moisture control in products ranging from pharmaceuticals to electronic components. This article explores the fundamental distinctions between molecular sieves and silica gel, focusing on their physical properties, moisture absorption capabilities, and typical applications, providing a clear understanding of their respective advantages and limitations.

Desiccant Basics

Molecular Sieve

Definition and Composition

A molecular sieve is a material with pores of uniform size. These pores match the dimensions of small molecules, thus enabling it to act as a sieve at the molecular level. Primarily made from synthetic zeolites, molecular sieves are manufactured by arranging silica and alumina into a three-dimensional framework. This structure is stabilized by the addition of cations like sodium, potassium, or calcium.

Common Types and Structures

Molecular sieves come in several types, each characterized by their specific pore sizes, typically measured in angstroms (Å). The most common types include:

- 3A Molecular Sieve: Effective at excluding molecules larger than 3 Å.

- 4A Molecular Sieve: Adsorbs molecules with a kinetic diameter up to 4 Å.

- 5A Molecular Sieve: Targets molecules up to 5 Å.

- 13X Molecular Sieve: Has a pore size of approximately 10 Å.

Each type has a unique framework structure that determines its suitability for different applications, ranging from gas purification to petrochemical processing.

Silica Gel

Definition and Composition

Silica gel is a form of silicon dioxide, similar to sand but with a porous, granular form. This material is synthetically produced from sodium silicate. Though called a gel, silica gel is solid, presented as translucent granules.

Forms and Variations

Silica gel varies mainly in pore size and the type of surface modification applied to enhance specific properties. Forms include:

- Fine Pore Silica Gel: Used for drying and moisture-sensitive applications.

- Wide Pore Silica Gel: Suited for applications requiring a larger pore size, such as chromatography.

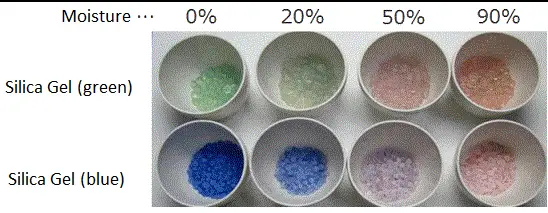

- Indicator Silica Gel: Contains a moisture indicator that changes color when saturated.

Physical Properties

Molecular Sieve

Particle Size and Shape

Molecular sieves are typically available in pellet, bead, or powder form. The shape and size can be engineered to specific requirements, affecting the flow rates and contact time in applications.

Porosity and Surface Area

Molecular sieves possess extremely high surface areas, which provide vast spaces for adsorption. Their microporous structure allows for a high degree of moisture adsorption compared to other desiccants.

Silica Gel

Particle Size and Shape

Silica gel particles are irregular in shape and vary in size from very fine to several millimeters in diameter. The specific size and shape will influence the gel’s drying capacity and rate.

Porosity and Surface Area

Silica gel features a network of microscopic pores that effectively trap moisture. Its surface area is significantly extensive, allowing it to adsorb high amounts of water vapor.

Moisture Absorption

Molecular Sieve

Absorption Capacity

Molecular sieves offer superior moisture absorption capacities, which can be precisely targeted based on the molecular sieve type. They are particularly effective in environments requiring low humidity levels.

Absorption Mechanism

The adsorption process in molecular sieves involves physical adsorption and ion exchange, which occur within their uniform pore structure. This mechanism is highly efficient and selective, making them ideal for critical applications.

Silica Gel

Absorption Capacity

Silica gel has a good moisture absorption capacity, though generally lower than molecular sieves when compared at low humidity levels. It performs exceptionally well at higher humidity conditions.

Absorption Mechanism

Moisture adsorption in silica gel occurs through capillary condensation within its pores and surface adsorption, which is effective across a broad range of temperatures and humidity levels.

Temperature Resistance

Molecular Sieve

Thermal Stability

Molecular sieves are highly stable under thermal conditions, maintaining integrity and performance at temperatures significantly higher than other desiccants can withstand.

Regeneration Temperatures

Regeneration of molecular sieves involves heating them to temperatures typically between 250°C and 300°C, which drives off the adsorbed moisture and restores their drying capacity.

Silica Gel

Thermal Stability

Silica gel also exhibits good thermal stability, suitable for use in various temperature ranges, though it tends to lose some adsorption capacity at higher temperatures compared to molecular sieves.

Regeneration Temperatures

Silica gel can be regenerated at temperatures ranging from 120°C to 180°C, making it reusable in many applications.

Applications

Molecular Sieve

Specific Industry Uses

Molecular sieves are crucial in industries where even trace amounts of moisture can cause significant issues, such as in natural gas processing, petrochemicals, and pharmaceuticals.

Advantages in Certain Environments

Their ability to adsorb moisture or gases selectively makes them particularly useful in controlled environments requiring precise humidity levels.

Silica Gel

Broad Applications

Silica gel is used widely across various industries, including electronics, food packaging, and pharmaceuticals, due to its versatility and ease of use.

Preferred Situations and Benefits

Its non-toxic nature and ability to adsorb a substantial amount of moisture make silica gel a preferred choice for protecting products during shipping and storage in less critical conditions.

Cost and Availability

Molecular Sieve

Market Trends

The market for molecular sieves is influenced by their critical applications in industries like petrochemicals, natural gas, and fine chemicals. As industries strive for more efficient processes and stricter environmental regulations, the demand for highly effective desiccants like molecular sieves continues to grow. Innovations in materials science are further driving the development of more efficient and capable molecular sieve materials.

Cost-effectiveness

Molecular sieves are generally more expensive than other desiccants. However, their high efficiency and the ability to be regenerated and reused make them a cost-effective solution over time. Industries that require precise moisture control find the initial higher cost acceptable due to the long-term savings in product stability and reduced waste.

Silica Gel

Market Availability

Silica gel is readily available worldwide and is produced in large quantities to meet the demand of a wide range of industries. Its widespread use in consumer products, including food and electronics packaging, ensures continuous production and improvements in manufacturing techniques.

Price Comparison

When compared to molecular sieves, silica gel is less expensive, making it a popular choice for general moisture control needs. The cost-effectiveness of silica gel, coupled with its broad availability, makes it an accessible option for both small-scale and large-scale applications.

Health and Safety

Molecular Sieve

Handling and Safety Precautions

Proper handling of molecular sieves is essential due to their chemical nature. Safety precautions include:

- Wearing gloves and eye protection to prevent skin and eye contact.

- Ensuring adequate ventilation to avoid inhalation of dust.

- Keeping the material dry prior to use to prevent premature adsorption of moisture.

Health Risks

Inhalation of dust from molecular sieves can cause respiratory irritation. Prolonged exposure to fine particles may lead to more severe respiratory issues if safety measures are not strictly followed. Always consult the material safety data sheet (MSDS) for specific health and safety guidelines.

Silica Gel

Safe Usage Guidelines

Silica gel is non-toxic and safe for use in a wide range of environments, including consumer product packaging. Key safety guidelines include:

- Avoiding ingestion, even though it is non-toxic, as the packets can pose a choking hazard.

- Handling with care to prevent dust generation, which can cause irritation.

Health Implications

The main health concern with silica gel comes from the potential for dust to cause respiratory irritation. In workplaces where silica gel is used in bulk, measures should be taken to manage dust and maintain good air quality.

Lifespan and Sustainability

Molecular Sieve

Durability

Molecular sieves have a high durability and can be regenerated multiple times with proper handling. This durability extends their lifespan significantly, often making them a one-time investment for many industrial applications.

Environmental Impact

Molecular sieves have a minimal environmental impact when disposed of properly. Their ability to be regenerated reduces the need for frequent replacement, decreasing waste production. Additionally, they do not degrade into harmful substances.

Silica Gel

Shelf Life

Silica gel has an excellent shelf life and can maintain its effectiveness for many years if kept in airtight conditions. Its stability and durability make it ideal for long-term storage applications.

Recycling and Disposal

Silica gel can be recycled in some cases, although the recycling processes are not as straightforward as those for molecular sieves. It is primarily disposed of in landfill sites, where it does not degrade or release harmful substances.

Choosing the Right Desiccant

Factors to Consider

When selecting a desiccant, several factors must be considered:

- Specific moisture control needs: Choose molecular sieves for precise control in sensitive environments.

- Budget constraints: Opt for silica gel for cost-sensitive projects.

- Regeneration capability: Consider whether the ability to regenerate the desiccant is necessary for your application.

Comparison Summary

Molecular sieves offer high precision and regeneration capabilities, making them suitable for critical applications. Silica gel, being more affordable and versatile, is well-suited for general moisture control tasks.

Recommendations Based on Needs

For industries requiring stringent control of moisture, molecular sieves are recommended due to their superior performance and adaptability. For everyday moisture problems, especially in consumer goods, silica gel provides a practical and economical solution.

Frequently Asked Questions

What are molecular sieves?

Molecular sieves are synthetic zeolite materials engineered to have a precise and uniform pore structure, making them highly effective at adsorbing gases and liquids based on molecular size. They are commonly used in applications requiring stringent moisture control or gas separation.

How does silica gel absorb moisture?

Silica gel absorbs moisture through physical adsorption and capillary condensation within its porous structure. Its effectiveness is influenced by the ambient temperature and humidity, making it versatile for use in a wide range of conditions.

Can molecular sieves be regenerated?

Yes, molecular sieves can be regenerated by heating them to high temperatures that release the trapped moisture or other substances. This regeneration process allows molecular sieves to be reused in several cycles, making them a cost-effective option in many industrial applications.

Are silica gel and molecular sieves environmentally friendly?

Both silica gel and molecular sieves are considered environmentally friendly desiccants. They do not degrade into hazardous compounds and can be disposed of safely. Additionally, both can be regenerated and reused, reducing waste and environmental impact.

What is the main difference between molecular sieve and silica gel?

The main difference lies in their moisture absorption mechanisms and capacity. Molecular sieves offer higher moisture adsorption capabilities in a controlled manner due to their uniform pore sizes, while silica gel provides versatile absorption properties suitable for less critical applications.

Conclusion

Understanding the differences between molecular sieves and silica gel is essential for selecting the most appropriate desiccant for a specific application. Each has distinct properties that can significantly affect the outcome in moisture-sensitive environments. By considering factors such as absorption efficiency, thermal stability, and cost-effectiveness, users can make informed decisions that enhance the longevity and reliability of their products.

Further exploration and consultation with industry experts can provide deeper insights into the applications and benefits of each desiccant type. This knowledge not only aids in making practical choices but also contributes to advancements in the fields where these desiccants are utilized, ensuring optimal performance and sustainability.