The distinctions between Distributed Control Systems (DCC) and Enterprise Data Centers (EDC) are pivotal for businesses seeking optimal technological solutions. Both systems play crucial roles in the management and dissemination of information across various industries. Although they cater to similar necessities, their functionalities and implications in the business landscape are distinct.

DCC refers to a control system typically used in industrial processes, where multiple subsystems are controlled by one or more controllers distributed throughout the system. On the other hand, EDC involves centralized management of data, services, and applications essential for corporate IT operations. Understanding these systems is critical for making informed decisions in technology investments.

In today’s rapidly evolving technological environment, both DCC and EDC systems are fundamental in enhancing operational efficiency and data handling capabilities. Their relevance spans across sectors such as manufacturing, utilities, and large-scale enterprises, emphasizing the importance of selecting the right system based on specific business needs and operational criteria.

DCC Explained

Definition and Basics

A Distributed Control System (DCC) is a sophisticated type of automated control system that is structured to manage complex industrial processes. Unlike traditional control systems that are centralized, a DCC distributes control functions across various elements within the system. This architecture allows for more effective and reliable monitoring and control of individual parts of the industrial process.

Key Features

DCC systems offer several defining features that set them apart:

- Redundancy: This ensures that in the event of a failure, another component can take over without disrupting the process.

- Scalability: Systems can be expanded with minimal impact on existing operations.

- Flexibility: They can be adapted to new processes and technologies.

- High Reliability: Due to their distributed nature, they provide robust performance even under demanding conditions.

Applications in Industry

Distributed Control Systems are primarily used in industries where precise and reliable control of various processes is critical. Some common applications include:

- Chemical Plants: Managing the complex chemical reactions and processes safely and efficiently.

- Oil and Gas: Monitoring and controlling extensive pipeline networks and refining processes.

- Pharmaceuticals: Ensuring precise conditions during the manufacturing of medicines.

- Power Generation: Controlling the generation and distribution of power in grids.

EDC Overview

Understanding EDC

An Enterprise Data Center (EDC) is a facility used by organizations to house computer systems and associated components. It is the central point for IT operations and equipment, focused on storing, managing, and disseminating data.

Core Characteristics

EDC systems are characterized by:

- High Security: Protecting data against breaches and intrusions.

- Robust Infrastructure: Engineered to support large scales of data and high-speed communications.

- Energy Efficiency: Designed to minimize energy consumption while maximizing performance.

Usage Scenarios

Enterprise Data Centers are crucial in scenarios where businesses need to manage vast amounts of data securely and efficiently. Typical uses include:

- Large Corporations: Handling employee data, customer databases, and transaction records.

- Financial Institutions: Managing transaction processing and financial data storage.

- Healthcare Providers: Storing large volumes of medical records and patient data securely.

Comparative Analysis

DCC vs. EDC: Core Differences

While both DCC and EDC serve critical roles in modern industry, their core purposes differ significantly:

- Operational Focus: DCCs are designed for continuous, reliable control over manufacturing or industrial processes. EDCs, however, focus on data management and IT services.

- Deployment: DCCs are usually distributed throughout the physical location of the process, while EDCs are centralized locations that can serve multiple locations or even global operations.

Technology and Methodology

The technology used in DCC involves real-time control systems and sensors to manage and monitor industrial processes. EDC, conversely, utilizes servers, storage solutions, and networking infrastructure to manage data.

Impact on User Experience

DCC enhances the operational efficiency of industries by minimizing downtime and optimizing process control. EDCs improve the user experience by offering faster data access, higher data reliability, and robust data protection.

Advantages of DCC

Enhanced Features

DCC systems offer:

- Advanced Process Control: Automated systems optimize the industrial processes.

- Real-Time Monitoring: Immediate feedback and control adjustments.

Cost Efficiency

Deploying a DCC can significantly reduce operational costs by:

- Reducing downtime.

- Minimizing manual intervention.

- Optimizing resource utilization.

User Adoption

The adoption of DCC is facilitated by its:

- Ease of integration into existing processes.

- User-friendly interfaces.

- Training and support provided by vendors.

Benefits of EDC

Agility and Flexibility

One of the key advantages of Enterprise Data Centers (EDC) is their agility and flexibility. These centers allow organizations to respond rapidly to changes in business needs or market conditions. EDCs facilitate:

- Quick Deployment of Resources: Adjusting to increases in data demand or new applications is streamlined.

- Flexibility in IT Solutions: Adapting to new technologies or software updates with minimal disruption.

This flexibility is vital for businesses in fast-paced industries where being able to pivot and adapt can be a significant competitive edge.

Scalability Factors

EDCs are designed to grow with the needs of the organization. Scalability in EDCs involves:

- Expansion Capacity: Easily adding more storage or processing power as needed.

- Modular Design: Scaling up operations without extensive modifications to existing infrastructure.

The ability to scale efficiently protects businesses against the growing pains that can occur with unexpected growth or sudden increases in data processing demands.

Integration Capabilities

EDCs excel in their ability to integrate seamlessly with various technologies and platforms, which is crucial for maintaining the continuity and efficiency of business operations. Integration capabilities include:

- Compatibility with Multiple Standards and Protocols: Ensuring smooth communication between disparate systems.

- Centralized Management Tools: Simplifying the oversight of IT resources and data flows across the organization.

Decision Factors

Choosing Between DCC and EDC

Selecting between a Distributed Control System (DCC) and an Enterprise Data Center (EDC) depends largely on the specific needs of a business. Factors influencing this decision include:

- Nature of Operations: DCC is preferred for industries focused on manufacturing or production, while EDCs are better suited to data-heavy sectors like finance or healthcare.

- Scalability Needs: Consider whether the business anticipates significant growth in data usage or operational complexity.

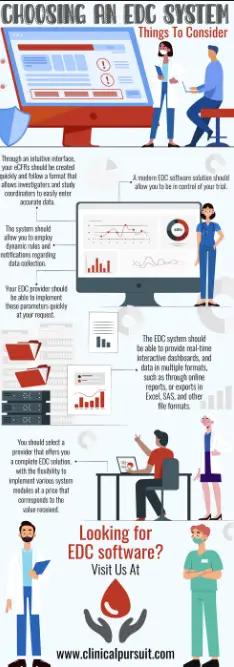

Factors to Consider

When deciding between DCC and EDC, organizations should evaluate:

- Cost Implications: Initial setup and ongoing maintenance costs.

- Technical Requirements: Specific technical needs such as real-time processing or large-scale data storage.

- Business Goals: Alignment with long-term strategic objectives.

Case Studies and Examples

Case studies highlight the practical benefits of DCC and EDC systems:

- Manufacturing Firm: Adopted DCC to enhance process automation, resulting in a 20% increase in production efficiency.

- Financial Services Provider: Utilized EDC to centralize data operations, improving data access times by 30% and enhancing security measures.

Future Trends

Innovations in DCC

Technological advancements in DCC are focused on enhancing efficiency and reliability. Future innovations may include:

- Integration with IoT: Enhancing process control through real-time data from IoT devices.

- Advanced Analytics: Using machine learning to predict system failures or maintenance needs.

Evolution of EDC

As digital demands continue to evolve, so too does the architecture of Enterprise Data Centers. Upcoming trends in EDC include:

- Green Data Centers: Increased focus on sustainability, using renewable energy sources and improving energy efficiency.

- Hyperconverged Infrastructure: Simplifying management and enhancing scalability through software-defined storage solutions.

Predicted Market Developments

The future of DCC and EDC is shaped by ongoing technological progress and changing business needs. Market predictions suggest:

- Greater Adoption of Cloud Services: Both DCC and EDC systems may increasingly integrate with cloud technologies to enhance flexibility and reduce costs.

- Enhanced Security Measures: As cyber threats evolve, both systems will likely incorporate more advanced security protocols to protect critical data and control operations.

Frequently Asked Questions

What is a Distributed Control System?

A Distributed Control System (DCC) is a platform used predominantly in industrial settings like manufacturing plants or refineries, where it helps to automate and streamline complex processes. This system distributes control elements close to plant operations, facilitating precise process control and real-time decision making.

How does an Enterprise Data Center operate?

An Enterprise Data Center (EDC) serves as the backbone of a company’s IT infrastructure, managing large volumes of data, hosting applications, and ensuring uninterrupted service delivery. It centralizes data storage, computation, and networking, thus enhancing organizational efficiency and data security.

What are the main differences between DCC and EDC?

While DCC is tailored for direct control over manufacturing processes or similar operations, EDC focuses more on data and service management across an entire organization. DCC excels in real-time operational control, whereas EDC is designed to support broad data storage, access, and computing services.

Which system is better for improving operational efficiency?

The choice between DCC and EDC depends on the specific needs of a business. DCC is preferable for industries requiring precise and efficient control of physical operations, while EDC is ideal for organizations needing robust data management and IT service continuity.

Conclusion

Choosing between a Distributed Control System and an Enterprise Data Center is a decision that impacts the core operations of any technology-reliant business. Each system offers unique advantages that can significantly enhance operational capabilities, depending on the specific demands of the business environment.

As technology continues to evolve, the importance of understanding these systems and their applications in various industries cannot be overstated. Businesses must assess their specific needs to determine the most suitable system, ensuring that they can leverage the best of technology to foster growth and efficiency.