Polymers are ubiquitous in our everyday lives, shaping various industries from automotive to healthcare. Among the diverse family of polymers, prepolymers and oligomers stand out due to their unique chemical structures and applications. Their distinction, while subtle, has significant implications for their use in various manufacturing processes and products.

Prepolymers are intermediate products used in the production of polyurethanes, characterized by their longer chain lengths and reactive end groups. Oligomers, on the other hand, are shorter polymer fragments that have not yet reached the molecular weight of traditional polymers. They play crucial roles in the formation of plastics, resins, and other polymeric materials.

The significance of prepolymers and oligomers extends beyond their definitions. Their chemical properties dictate their behavior in reactions, influencing everything from the durability of materials to their environmental impact. This foundational understanding is critical for advancing material science and optimizing product performance across multiple sectors.

Definitions

What is a Prepolymer?

A prepolymer is a type of polymer that has not yet fully polymerized. These materials are in a state where they possess reactive groups, typically at the ends of their molecular chains, which are capable of undergoing further reactions to form more complex structures. Prepolymers are pivotal in the manufacture of polyurethanes and other versatile polymers, allowing for controlled reactions that tailor material properties according to specific needs.

What is an Oligomer?

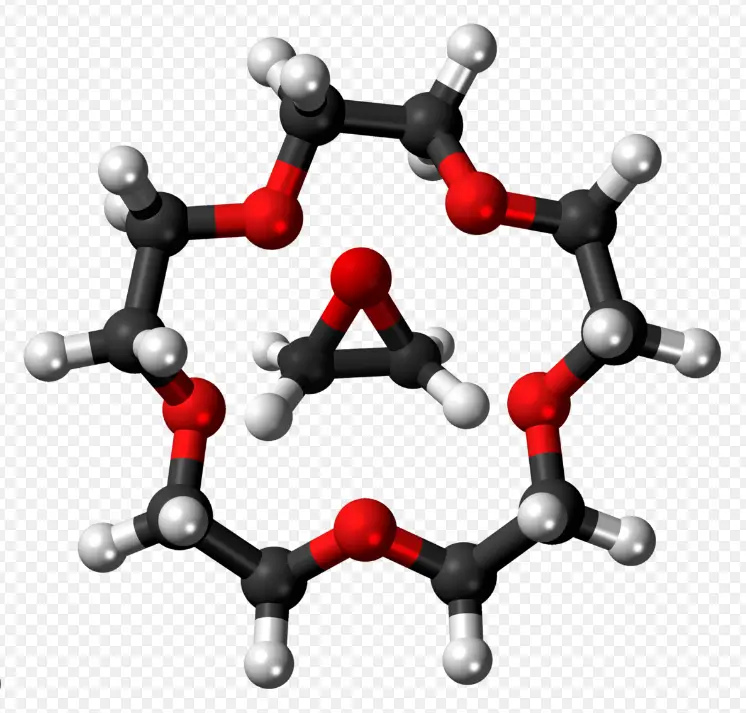

An oligomer refers to a molecular assembly made up of a few repeating units, unlike polymers which consist of many repeats. Oligomers occupy a middle ground between monomers (single units) and long-chain polymers, usually containing between two and twenty monomer units. These structures are crucial in the early stages of polymerization processes and are often used to modify the properties of final polymer products, including their viscosity and melting points.

Chemical Structure

Basic Structure of Prepolymers

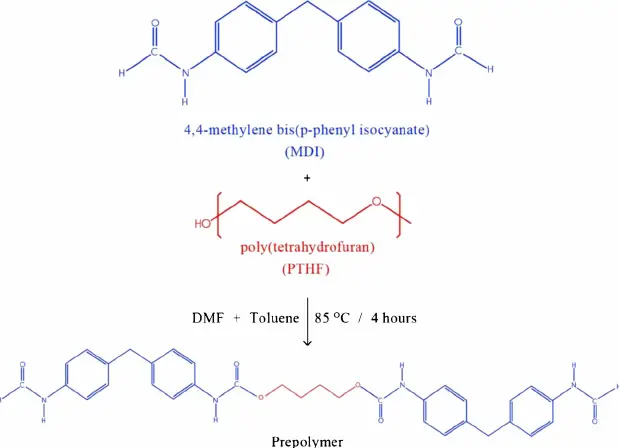

The chemical structure of prepolymers is defined by their active end groups, which are typically isocyanate groups in the case of polyurethane prepolymers. These groups are highly reactive and enable prepolymers to bond with other chemical entities, such as water or polyols, to form stable bonds. This reactivity is crucial for the creation of networks necessary for durable polyurethane materials.

Basic Structure of Oligomers

Oligomers, though similar to prepolymers in being intermediate forms, have a simpler structure with fewer reactive sites. The typical oligomer may have functional groups only at the ends or at strategic positions along the chain. These structures are significant as they determine the oligomer’s ability to integrate into larger polymer matrices, influencing the final material’s properties like flexibility, strength, and resistance to degradation.

Production Processes

How Prepolymers are Made

- Step 1: Synthesis of the base monomer

- Step 2: Reaction of the monomer with a catalyst to create a reactive prepolymer

- Step 3: Purification and testing for quality assurance

Prepolymers are typically produced through a two-step process. First, a monomer with reactive end groups is synthesized. This monomer is then reacted under controlled conditions with a catalyst to promote the formation of prepolymer chains. The resulting material is then purified to remove any unreacted monomers and impurities, ensuring that the prepolymer will perform as expected in subsequent applications.

How Oligomers are Produced

- Step 1: Selecting appropriate monomer units

- Step 2: Controlled polymerization

- Step 3: Termination and extraction of oligomers

The production of oligomers involves selecting specific monomers that will form the desired oligomer structure. These monomers undergo a controlled polymerization process, often involving temperature and pressure adjustments to foster the right reaction environment. Once the desired degree of polymerization is achieved, the reaction is terminated, and the oligomers are extracted for further use.

Key Properties

Properties of Prepolymers

Prepolymers are known for their reactivity and versatility. Due to their reactive end groups, prepolymers can be tailored to have high degrees of cross-linking, which results in materials that are robust, durable, and resistant to chemicals and physical stress. Their properties can be precisely controlled during the manufacturing process, making them ideal for applications requiring specific material characteristics.

Properties of Oligomers

Oligomers exhibit distinct properties such as lower viscosity and greater ease of processing compared to high molecular weight polymers. These characteristics make oligomers particularly useful in applications like paint formulations, where they enhance the flow and spreading qualities of the paint without compromising on the quality of the film formed.

Applications

Uses of Prepolymers

Prepolymers are extensively used in the production of polyurethane foams, which are common in furniture, automotive interiors, and insulation materials. Their ability to form rigid or flexible foams when reacted with other chemicals makes them invaluable in a wide range of industrial and commercial products.

Uses of Oligomers

Oligomers find their applications in the manufacture of composite materials, coatings, and adhesives. Their lower molecular weight makes them ideal for applications requiring controlled flow properties and rapid curing times, such as in the electronics industry for encapsulating components.

Advantages and Disadvantages

Benefits of Prepolymers

Prepolymers offer a range of benefits that make them attractive for various industrial applications:

- Enhanced Performance: Their ability to be customized for specific tasks allows manufacturers to engineer materials with superior mechanical properties such as toughness, elasticity, and resistance to environmental factors.

- Improved Adhesion: Prepolymers can be formulated to enhance bonding characteristics, crucial for applications in coatings and adhesives.

- Efficient Production: Due to their reactive nature, prepolymers reduce curing times and energy consumption during the manufacturing process, leading to more efficient production cycles.

Drawbacks of Prepolymers

Despite their advantages, prepolymers come with several drawbacks:

- Sensitivity to Conditions: Prepolymers can be sensitive to moisture and temperature, which can affect their storage and handling requirements.

- Health Risks: The reactive isocyanate groups in prepolymers can pose health risks, necessitating strict safety protocols during handling.

- Cost: The specialized synthesis and purification processes can make prepolymer-based products more expensive compared to those made with traditional polymers.

Benefits of Oligomers

Oligomers also provide several notable benefits:

- Versatility: They are used to modify the properties of a polymer, such as reducing viscosity, which can enhance processing and application properties.

- Faster Curing Times: Their structure allows for quicker curing, beneficial in fast-paced production environments.

- Energy Efficiency: Oligomers can be synthesized at lower temperatures and require less energy, contributing to more sustainable manufacturing practices.

Drawbacks of Oligomers

However, oligomers are not without their challenges:

- Limited Physical Properties: Due to their lower molecular weight, oligomers may not provide the same strength and durability as higher molecular weight polymers.

- Compatibility Issues: They must be carefully matched with other components in a formulation to ensure optimal performance, which can complicate product development.

- Regulatory Challenges: Some oligomers can be subject to stringent regulations due to their potential environmental and health impacts.

Comparison

Direct Comparison of Properties

When directly comparing the properties of prepolymers and oligomers:

- Molecular Weight: Prepolymers generally have higher molecular weights compared to oligomers, leading to stronger and more durable materials.

- Reactivity: Prepolymers are more reactive, which while beneficial for certain applications, also requires careful handling and storage.

- Usability: Oligomers, with their lower viscosity, are easier to process and apply, particularly in thin film applications like coatings and adhesives.

Comparative Analysis of Applications

The applications of prepolymers and oligomers often overlap, but their differences dictate their suitability for specific uses:

- Prepolymers are preferred in applications requiring robust materials, such as in the automotive and aerospace industries for insulation and structural components.

- Oligomers are favored in applications like paints and coatings, where ease of application and fast curing are beneficial.

Market Trends

Recent Advancements in Prepolymer Technology

Recent advancements in prepolymer technology focus on enhancing their environmental sustainability and safety:

- Bio-based Prepolymers: Development of prepolymers derived from renewable resources, reducing dependency on fossil fuels and lowering environmental impact.

- Non-isocyanate Prepolymers: Innovations aiming to replace hazardous isocyanate groups with safer alternatives that offer similar performance characteristics.

Innovations in Oligomer Production

In the field of oligomers, innovations are geared towards improving their functionality and environmental profile:

- Functional Oligomers: Enhanced oligomers with specific functional groups that cater to niche applications, such as UV-curable coatings and 3D printing materials.

- Green Synthesis Processes: Techniques that reduce solvent use and energy consumption during oligomer synthesis are becoming more prevalent, reflecting the industry’s push towards greener manufacturing practices.

Environmental Impact

Ecological Considerations of Prepolymers

The ecological impact of prepolymers is a growing concern, prompting research into biodegradable and recyclable prepolymer options. Efforts are also being made to minimize the release of harmful byproducts during their production and use.

Ecological Considerations of Oligomers

Similar to prepolymers, the environmental impact of oligomers is significant, particularly in terms of their persistence and potential toxicity. Advances are being made in developing biodegradable oligomers and methods to reduce their ecological footprint through better waste management practices and sustainable synthesis techniques.

Frequently Asked Questions

What are Prepolymers?

Prepolymers are low-molecular-weight polymers that have reactive end groups capable of further polymerization. They serve as precursors in the synthesis of more complex polymer structures, particularly useful in creating customizable polyurethane materials with specific properties.

How are Oligomers Used?

Oligomers are used primarily as building blocks in the synthesis of high molecular weight polymers. They find applications in coatings, adhesives, and resins, where they help control the properties of the final product such as viscosity, curing time, and mechanical strength.

What Distinguishes Prepolymers from Oligomers?

The key difference between prepolymers and oligomers lies in their molecular weight and structure. Prepolymers have longer chains and more reactive sites, making them suitable for applications requiring robust and durable materials. Oligomers, with their shorter chains, are pivotal in applications that benefit from lower viscosity and quicker reaction times.

Are Prepolymers Environmentally Friendly?

The environmental impact of prepolymers depends on their chemical composition and usage. Some prepolymers can be designed to be more eco-friendly, breaking down more easily or requiring less energy in production. However, the overall ecological footprint also depends on their life cycle and disposal methods.

Conclusion

In reviewing the roles and characteristics of prepolymers and oligomers, we uncover the intricacies that define their applications and impact. These materials are not just chemical curiosities but are central to the advancement of modern material sciences. Their proper understanding and utilization can lead to innovations in sustainability and performance that shape future technologies.

The ongoing development in the field of polymer chemistry promises to enhance the capabilities of prepolymers and oligomers. As research continues to evolve, these substances will undoubtedly play pivotal roles in crafting materials that are not only effective but also environmentally considerate and economically viable.