Phenol and nonylphenol, two distinct organic compounds, play significant roles in various industrial applications yet differ considerably in their chemical properties and environmental impacts. Both substances are crucial in the production of numerous commercial products, but their differences necessitate careful consideration when used in manufacturing and other processes. Phenol, a simpler compound, is often overshadowed by its more complex derivative, nonylphenol, known for its unique characteristics and uses.

Phenol and nonylphenol differ primarily in their chemical structure, production processes, and applications. Phenol, also known as carbolic acid, is a basic aromatic compound used extensively as a precursor in the manufacture of plastics and pharmaceuticals. Nonylphenol, on the other hand, is a derivative of phenol consisting of a phenol ring bonded to a nonyl chain, which affects its physical and chemical properties and makes it suitable for use in detergents and industrial cleaning agents.

Understanding the chemical properties of both substances is crucial due to their varying toxicity and environmental impacts. Phenol can be toxic and corrosive, requiring careful handling and specific safety measures. Nonylphenol is particularly concerning from an environmental standpoint due to its persistence and potential to act as an endocrine disruptor, affecting aquatic life even at low concentrations. These differences underscore the importance of stringent regulations and informed use in industrial applications.

Chemical Structures

Description of Phenol

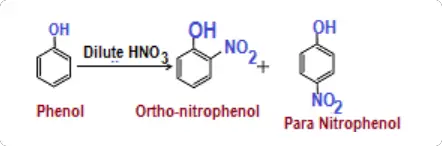

Phenol, also known scientifically as hydroxybenzene, is a basic aromatic organic compound with the molecular formula C6H5OH. It consists of a benzene ring bonded to a hydroxyl group, making it one of the simplest of the phenol class of compounds. At room temperature, phenol appears as a white crystalline solid, often with a distinctive, sweet yet pungent odor. The simplicity of its structure lends phenol to a variety of chemical and industrial applications, particularly as a precursor to more complex compounds.

Description of Nonylphenol

Nonylphenol is a derivative of phenol characterized by the presence of a nonyl chain, which is essentially a nine-carbon tail, attached to the phenol ring. This alteration in structure significantly changes its physical and chemical properties compared to its parent compound, phenol. Nonylphenol is typically oily, light-colored, and solid at room temperature. The addition of the nonyl group makes nonylphenol more hydrophobic (water-repelling) and less biodegradable, contributing to its environmental persistence.

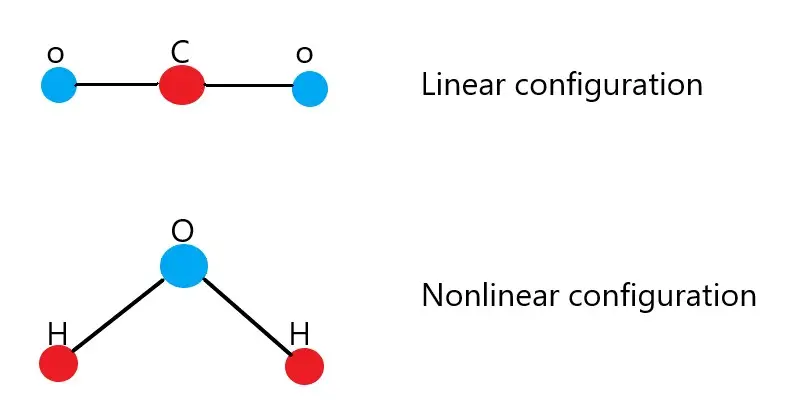

Structural Comparison

Comparing the structures of phenol and nonylphenol reveals significant differences:

- Phenol has a relatively simple structure with high water solubility due to its hydroxyl group.

- Nonylphenol, however, with its bulky nonyl side chain, is less soluble in water but more soluble in oil and fats. These structural distinctions not only affect their physical properties but also influence their chemical reactivity and biological interactions.

Production Processes

How Phenol is Produced

Phenol production predominantly involves the cumene process, which is an industrial scale method:

- Cumene Oxidation: Cumene (isopropylbenzene) is first oxidized by air to form cumene hydroperoxide.

- Acid-Catalyzed Cleavage: The hydroperoxide is then subjected to acid-catalyzed cleavage, producing phenol and acetone as co-products.

This method is favored for its efficiency and the valuable co-production of acetone, widely used as a solvent and in other chemical syntheses.

How Nonylphenol is Produced

The production of nonylphenol typically follows the alkylation of phenol with nonenes in the presence of an acid catalyst:

- Alkylation Reaction: Phenol is reacted with nonenes (propylene trimers) using an acid catalyst, leading to the attachment of the nonyl group to the phenol ring.

- Purification: The reaction mixture is purified to increase the yield of nonylphenol, focusing on removing unreacted phenol and other byproducts.

Comparative Analysis of Production Methods

The cumene process for phenol is highly optimized and efficient, making it a staple in chemical manufacturing. In contrast, the production of nonylphenol involves additional complexity due to the need for specific alkylation conditions and purification steps to achieve the desired nonylated product. This reflects a typical difference in producing simpler versus more complex organic molecules.

Physical Properties

Boiling Points, Melting Points

- Phenol: Boiling point at 181°C, melting point at 40.5°C.

- Nonylphenol: Boiling point ranges from 290°C to 300°C, melting point around 40°C to 46°C depending on the specific isomer.

Solubility and Appearance

- Phenol: Soluble in water, appears as white crystals.

- Nonylphenol: Oily, light-colored solid, insoluble in water but soluble in oils.

Differences in Physical Behavior

The key differences in physical behavior between phenol and nonylphenol can be largely attributed to their solubility properties. Phenol’s higher water solubility makes it more reactive and easier to handle in aqueous solutions, whereas nonylphenol’s oil solubility suits applications requiring hydrophobic properties.

Applications and Uses

Common Uses of Phenol

Phenol is extensively used in:

- Resin Production: For making phenolic resins, an essential component in the production of molded products and insulation materials.

- Pharmaceuticals: As a precursor in the synthesis of many drugs, including aspirin.

- Chemical Industry: In the synthesis of dyes, plastics, and herbicides.

Common Uses of Nonylphenol

Nonylphenol finds its applications primarily in:

- Surfactants: As a key ingredient in the production of nonionic surfactants used in industrial cleaning products.

- Plastic Manufacturing: As a stabilizer in making plastics more durable and heat-resistant.

- Environmental Management: Used in oil recovery and pesticide formulations, though restricted in many regions due to environmental concerns.

Sector-Specific Applications

Both chemicals are pivotal in their respective sectors, with phenol serving critical roles in healthcare and construction, while nonylphenol is important in industrial cleaning and agricultural practices. The specific applications reflect their chemical nature and the sectors’ requirements for particular physical and chemical properties.

Health and Environmental Impact

Toxicity Levels of Phenol

Phenol, while useful in many industrial applications, is toxic to humans and the environment. Its primary route of exposure is through skin contact, inhalation, or ingestion, which can cause a range of acute and chronic health effects. Exposure to phenol can lead to:

- Skin and Eye Irritation: Direct contact can cause severe burns and eye damage.

- Systemic Toxicity: High levels of exposure can affect the central nervous system, leading to symptoms like headache, dizziness, and in severe cases, coma.

- Organ Damage: Chronic exposure has been linked to liver and kidney damage.

Environmental exposure to phenol is also concerning. It is toxic to aquatic life, with the potential to cause long-term adverse effects in aquatic environments.

Toxicity Levels of Nonylphenol

Nonylphenol is recognized for its endocrine-disrupting properties, posing significant risks to wildlife, particularly aquatic organisms. It mimics natural hormones and can disrupt the reproductive systems of fish and other aquatic species. For humans, nonylphenol exposure can lead to similar health issues as phenol, but with added concerns due to its persistence in the environment and ability to accumulate in living organisms.

Regulatory Status and Concerns

Both phenol and nonylphenol are subject to strict regulations across many countries due to their health and environmental risks. For instance:

- Phenol: Regulated in terms of exposure limits and release into the environment.

- Nonylphenol: Banned or restricted in many applications, especially in detergents in the European Union, due to its environmental persistence and toxicity.

Safety and Handling

Handling Precautions for Phenol

Proper safety measures are critical when handling phenol to minimize health risks:

- Personal Protective Equipment (PPE): Use of gloves, goggles, and protective clothing.

- Ventilation: Ensuring good ventilation in areas where phenol vapors might be present.

- Emergency Procedures: Ready access to washing facilities and first aid in case of exposure.

Handling Precautions for Nonylphenol

Due to its toxicity and environmental impact, handling nonylphenol requires even stricter precautions:

- Containment: Use of containment to prevent any environmental release.

- Specialized PPE: Use of respirators in addition to standard PPE to protect against inhalation of particles.

- Spill Management: Immediate response strategies for spills to prevent environmental contamination.

Best Practices in Industrial Settings

Implementing best practices is essential for safe operations when working with hazardous chemicals like phenol and nonylphenol:

- Training: Regular training sessions for workers on the hazards and safe handling procedures.

- Monitoring: Continuous monitoring of air and water quality in and around industrial sites.

- Regulatory Compliance: Adherence to local and international safety and environmental regulations.

Market Trends

Consumption Patterns for Phenol

Phenol consumption has been steady due to its widespread use in resins and other industrial applications. The market is driven by the demand in sectors such as:

- Automotive: For manufacturing composites and insulation materials.

- Electronics: In the production of circuit boards and other components.

Consumption Patterns for Nonylphenol

The use of nonylphenol has seen a decline in regions with strict environmental regulations but continues in areas where regulation is less stringent. It remains in use primarily in:

- Industrial Cleaning Agents: Where its properties are still valued despite the environmental risks.

- Manufacturing Processes: As a stabilizer in plastic manufacturing.

Future Market Projections

The market for phenol is expected to grow moderately, driven by advances in industrial technology and increased demand for phenolic resins. In contrast, the market for nonylphenol is likely to contract further as regulatory pressures increase and safer alternatives become more prevalent. The shift towards environmentally friendly chemicals is expected to reshape the landscape for these traditional compounds.

Frequently Asked Questions

What is phenol used for?

Phenol is primarily used in the production of plastics, particularly in creating phenolic resins, which are essential for manufacturing laminates, insulation, and other composite materials. It is also used in the synthesis of pharmaceuticals and as a precursor in the production of herbicides.

How is nonylphenol produced?

Nonylphenol is produced by the alkylation of phenol with nonenes in the presence of an acid catalyst. This process leads to the formation of nonylphenol, which is used extensively in the manufacture of nonionic surfactants, essential in industrial detergents and cleaning agents.

What are the environmental risks of nonylphenol?

Nonylphenol is considered environmentally hazardous due to its persistence and bioaccumulative nature. It is known to disrupt endocrine systems in wildlife, particularly aquatic organisms, leading to reproductive and developmental issues. As a result, its use and disposal are highly regulated in many countries.

Why is phenol considered hazardous?

Phenol is hazardous due to its corrosive nature and toxicity. Exposure to phenol can cause severe irritation to the skin, eyes, and respiratory system. Ingestion or prolonged exposure can lead to systemic toxicity, affecting the central nervous system, cardiovascular system, and kidneys.

Conclusion

The differentiation between phenol and nonylphenol is vital for their safe and effective use in various industrial and consumer products. While both chemicals are foundational in modern manufacturing processes, their distinct properties necessitate different handling and safety protocols. The contrasting environmental impacts, particularly the higher persistence and toxicity of nonylphenol, highlight the importance of careful management and regulatory oversight to mitigate adverse effects.

As industries and regulations evolve, understanding and addressing the environmental and health implications of these chemicals remain paramount. Continued research and adaptation of safer alternatives and practices will be crucial in minimizing the ecological footprint of phenol and nonylphenol, ensuring their sustainable use in the future.