Membrane filtration and direct inoculation are pivotal methods used in the fields of microbiology, water treatment, and pharmaceuticals for the detection and analysis of microorganisms. Each technique offers a unique approach to isolating and identifying bacteria, viruses, and other microorganisms, catering to specific requirements of accuracy, sensitivity, and application. As the need for more precise and efficient microbial detection methods grows, understanding the differences between these two techniques becomes crucial for professionals across various industries.

The primary difference between membrane filtration and direct inoculation lies in their methodologies and applications. Membrane filtration involves passing a liquid through a filter that captures microorganisms, which are then transferred to a growth medium. Direct inoculation, on the other hand, skips the filtration step, allowing samples to be placed directly onto or into a culture medium. This fundamental distinction impacts the sensitivity, accuracy, and appropriateness of each method for different types of samples and testing needs.

Membrane filtration is renowned for its ability to test large volumes of samples, especially in water quality testing and pharmaceutical manufacturing, where the detection of even a single microorganism is critical. Direct inoculation is favored for its simplicity and speed, particularly in clinical microbiology and food safety testing, where rapid results can be more valuable. Both methods have their place, with the choice between them depending on the specific requirements of the test being conducted.

Core Principles

Membrane Filtration Explained

Basics and Process

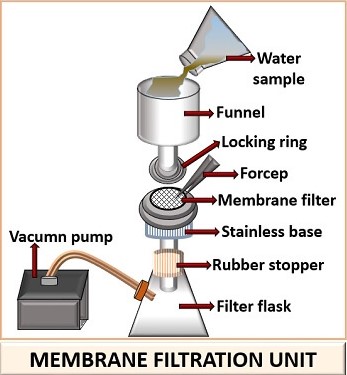

Membrane filtration is a technological process used to separate particles from a liquid for the analysis of microorganisms. It utilizes a membrane filter, a thin layer with specific pore sizes that allow liquid to pass while trapping particles, including bacteria, fungi, and protozoa.

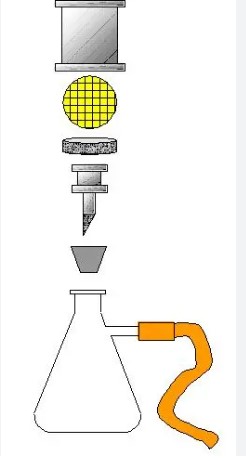

- Step 1: Preparation of the sample. The liquid sample is prepared for filtration, ensuring it’s free from particles that could clog the membrane.

- Step 2: Filtration process. The sample is passed through the membrane filter using a vacuum or pressure system.

- Step 3: Transfer to culture media. The filter, now containing the trapped microorganisms, is placed on or in a nutrient-rich medium.

- Step 4: Incubation. The culture media is incubated, allowing microorganisms to grow and become detectable.

Key Applications

Membrane filtration is widely used in:

- Water Quality Testing: For assessing drinking water and wastewater for harmful pathogens.

- Pharmaceutical Manufacturing: To ensure products are free from microbial contamination.

- Food and Beverage Industry: For microbial analysis to guarantee safety and quality.

Direct Inoculation Defined

Process Overview

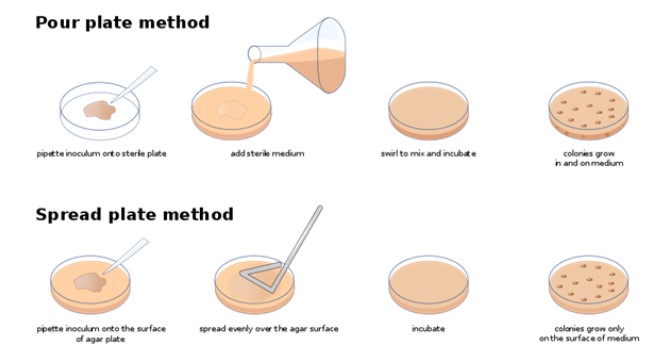

Direct inoculation is a straightforward method where a sample is placed directly onto or into a culture medium without prior separation. This technique is simple and efficient, making it ideal for samples with higher concentrations of microorganisms.

- Step 1: Sample preparation. The sample is prepared, often requiring dilution to manage the concentration of microorganisms.

- Step 2: Inoculation. The prepared sample is applied directly to the culture medium.

- Step 3: Incubation. The inoculated medium is incubated, promoting the growth of microorganisms for analysis.

Primary Uses

This method is primarily used in:

- Clinical Microbiology: For rapid identification of pathogens in patient samples.

- Quality Control in Food and Beverage Industries: To quickly test products for microbial contamination.

Comparative Analysis

Process Differences

Filtration vs. Inoculation Steps

- Membrane Filtration involves additional steps of filtering the sample before analysis, which can isolate microorganisms more effectively.

- Direct Inoculation skips the filtration step, offering a quicker but less sensitive method.

Equipment and Setup

- Membrane Filtration requires specialized equipment, including a filtration apparatus and vacuum system.

- Direct Inoculation can often be performed with simpler lab equipment, such as pipettes and culture dishes.

Accuracy and Sensitivity

Detecting Microorganisms

- Membrane Filtration is highly sensitive, capable of detecting low levels of microorganisms in large volumes of sample.

- Direct Inoculation is less sensitive but efficient for samples with higher microbial loads.

Limitations and Advantages

- Membrane Filtration is limited by the need for specialized equipment and the potential for filter clogging.

- Direct Inoculation offers speed and simplicity but may miss low-concentration samples.

Time Efficiency

Duration of Testing Methods

- Membrane Filtration typically takes longer due to the additional filtration step.

- Direct Inoculation provides faster results, ideal for urgent analysis.

Speed Comparison

Direct inoculation stands out for its rapid turnaround time, crucial in clinical settings or when product safety is at stake.

Applications and Scenarios

Membrane Filtration Use Cases

Water Quality Testing

Membrane filtration is essential for detecting pathogens in drinking and recreational waters, safeguarding public health.

Pharmaceutical Applications

It ensures that pharmaceutical products are free from microbial contamination, critical for patient safety.

Direct Inoculation Scenarios

Clinical Microbiology

Direct inoculation is invaluable for quickly identifying pathogens in patient samples, aiding in the prompt treatment of infections.

Food and Beverage Industry

This method is used for rapid testing of products for microbial safety, ensuring compliance with health standards.

Cost Implications

Initial and Ongoing Costs

The financial aspect of choosing between membrane filtration and direct inoculation involves considering both initial and ongoing expenses. Membrane filtration requires more sophisticated equipment, such as filtration units and vacuum systems, which can represent a significant upfront cost. Direct inoculation, by comparison, needs less specialized equipment, often resulting in lower initial costs.

Equipment and Material Expenses

For membrane filtration, the primary expenses include:

- Filtration apparatus

- Membrane filters

- Vacuum pumps

Direct inoculation’s main expenses are:

- Culture media

- Petri dishes or culture tubes

Maintenance and Operational Costs

Membrane filtration involves additional costs for filter replacement and maintenance of the filtration system. Direct inoculation has fewer ongoing costs, primarily related to the purchase of culture media and disposables.

Cost-Benefit Analysis

Evaluating the return on investment (ROI) and cost-effectiveness of these methods requires considering their benefits in relation to their costs. Membrane filtration, while more expensive, offers high sensitivity and can test large volumes, making it invaluable in scenarios where detecting even a single pathogen is critical. Direct inoculation’s affordability and speed make it suitable for applications requiring rapid results.

ROI Considerations

- Membrane Filtration: Higher initial investment but offers precision and versatility.

- Direct Inoculation: Lower cost and faster results but may require additional tests for low-concentration samples.

Cost-Effectiveness for Various Scales

For large-scale applications, like municipal water testing, the efficiency and comprehensiveness of membrane filtration might justify the higher costs. In smaller settings or when quick decisions are needed, direct inoculation’s cost savings and speed can be more valuable.

Advantages and Challenges

Benefits of Membrane Filtration

Versatility and Sensitivity

Membrane filtration is highly versatile, suitable for a wide range of applications from water testing to pharmaceutical quality control. Its high sensitivity makes it capable of detecting very low levels of contamination.

Applications Range

This method is used across various sectors, demonstrating its broad applicability in ensuring safety and compliance with health standards.

Advantages of Direct Inoculation

Simplicity and Direct Approach

The ease of use and straightforward nature of direct inoculation make it accessible for many laboratories, requiring minimal training.

Speed and Accessibility

Direct inoculation’s fast turnaround times are crucial in clinical settings and industries where decisions must be made quickly.

Challenges and Solutions

Overcoming Common Obstacles

Both methods face their challenges, such as the risk of filter clogging in membrane filtration and the potential for missing low-level contaminants in direct inoculation. Solutions include:

- Regular equipment maintenance

- Proper training of laboratory personnel

- Employing both methods in tandem for comprehensive analysis

Optimizing Techniques

Improvements in technology and methodology can help mitigate these challenges, enhancing efficiency and reliability.

Decision Factors

Choosing Between Methods

Selecting the appropriate method depends on several criteria:

- Sample type

- Required sensitivity

- Speed of results

- Budget constraints

Criteria for Selection

Considering these factors ensures the chosen method aligns with the specific needs of the testing scenario.

Application-Specific Considerations

For example, in pharmaceutical manufacturing, the zero-tolerance policy for contamination may necessitate membrane filtration. In contrast, for routine checks of food products, direct inoculation’s speed may be more beneficial.

Future Trends and Developments

Technological Advancements

Ongoing research and development are likely to introduce new technologies that could make both methods more efficient, cost-effective, and easier to use.

Emerging Applications

As the demand for rapid and accurate microbial detection grows, we can expect to see these methods applied in new and innovative ways, from environmental monitoring to the development of new therapeutic products.

FAQs

What is membrane filtration?

Membrane filtration is a microbiological technique that separates microorganisms from a sample by passing it through a microporous membrane. This method is especially useful for analyzing large volumes of fluid, where the membrane captures the microorganisms, which are then grown on culture media for identification and analysis.

How does direct inoculation differ from membrane filtration?

Direct inoculation is a simpler method where a sample is placed directly onto or into a culture medium without the preliminary step of filtration. It is generally faster than membrane filtration but may be less sensitive in detecting low levels of microorganisms, making it suitable for samples with higher concentrations of bacteria.

When should I use membrane filtration over direct inoculation?

Membrane filtration should be used when testing samples that may contain very low concentrations of microorganisms, such as in pharmaceutical or drinking water quality testing. It’s particularly effective for samples where detecting even a single pathogen is crucial. Direct inoculation is more suited for samples with higher bacterial loads or when quick results are paramount.

Can membrane filtration and direct inoculation be used together?

Yes, in some cases, both methods can be used in tandem to maximize the detection of microorganisms. For example, membrane filtration can concentrate the microorganisms from a large sample volume, and direct inoculation can then be used for rapid testing of concentrated samples. This combination can enhance both sensitivity and speed.

Conclusion

In conclusion, membrane filtration and direct inoculation serve as essential tools in the microbiological analysis, each with unique advantages tailored to specific testing needs. Membrane filtration stands out for its ability to detect minimal quantities of microorganisms in large sample volumes, making it indispensable in fields requiring high sensitivity. Direct inoculation, with its simplicity and rapid turnaround, is invaluable for applications where speed is of the essence. Understanding the distinct qualities and applications of these methods empowers professionals to make informed decisions, ensuring accurate and efficient microbial detection across diverse scenarios.

The choice between membrane filtration and direct inoculation hinges on the specific requirements of the testing scenario, including the sample type, desired sensitivity, and the necessity for rapid results. As advancements continue to shape these methodologies, staying informed about their capabilities and limitations remains crucial for leveraging their benefits to the fullest. This knowledge not only enhances the precision of microbial detection but also supports the overarching goal of safeguarding public health and ensuring the safety of products and services across industries.