Elemental analysis plays a crucial role in various scientific fields, from environmental monitoring to food safety. Techniques such as dry ashing and wet digestion are foundational in preparing samples for such analysis. Each method involves distinct processes aimed at isolating specific elements for further examination, highlighting the diversity of approaches in laboratory procedures.

Dry ashing and wet digestion are two primary techniques for preparing samples in elemental analysis. Dry ashing involves heating samples to high temperatures to remove organic constituents, leaving a residue of inorganic ash. In contrast, wet digestion uses liquid chemicals to decompose the sample, often under heat, to achieve a solution rich in the target elements.

While both techniques aim to prepare samples for accurate elemental analysis, they differ significantly in terms of procedure, safety, and suitability for various sample types. Understanding these differences helps laboratories choose the most appropriate method based on the nature of the sample and the elements of interest.

Dry Ashing

What is Dry Ashing?

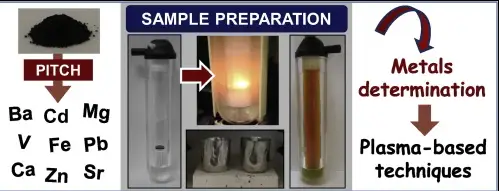

Dry ashing refers to a sample preparation technique used primarily in analytical chemistry where organic materials are decomposed by exposing them to high temperatures in the absence of oxygen. This process leaves behind a residue predominantly composed of inorganic ash, which can be further analyzed for its elemental content.

Key Steps

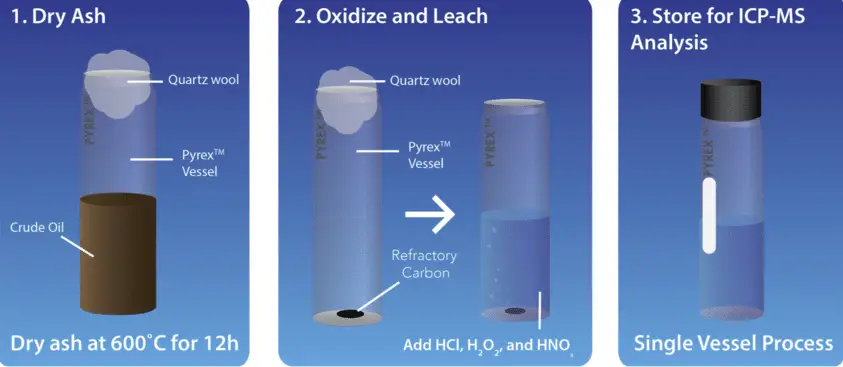

The procedure for dry ashing typically follows these steps:

- Sample Preparation: Samples are cleaned and, if necessary, cut into smaller pieces to ensure even heat distribution.

- Heating: The prepared samples are placed in a furnace and heated to temperatures ranging from 450°C to 800°C.

- Cooling and Collecting Ash: After a specified duration, usually several hours to overnight, the furnace is turned off to allow the samples to cool. The residual ash is then collected for analysis.

Applications and Benefits

Dry ashing is widely used in various fields such as environmental science, metallurgy, and food analysis. The benefits of dry ashing include:

- Minimized Chemical Use: Unlike wet digestion, dry ashing does not require the use of corrosive chemicals.

- Stability for Heat-Resistant Samples: It is ideal for samples that can withstand high temperatures without decomposing.

- Ease of Automation: The process can be easily automated, reducing the need for manual intervention and decreasing the potential for contamination.

Common Challenges

While beneficial, dry ashing comes with its own set of challenges:

- Time-Consuming: The process is generally slower than other methods due to the long heating periods.

- Limited to Certain Sample Types: Not all samples are suitable for high-temperature exposure.

- Loss of Volatile Elements: Elements that vaporize at high temperatures cannot be recovered or analyzed.

Wet Digestion

What is Wet Digestion?

Wet digestion is a technique where chemical solvents, typically acids, are used to decompose organic material in a sample at elevated temperatures and pressures. This method is often preferred for samples that contain volatile elements or are too delicate for high-temperature exposures.

Key Steps

The key steps in wet digestion include:

- Sample Preparation: Samples are precisely weighed and sometimes homogenized.

- Acid Addition: Specific acids, like nitric acid or hydrochloric acid, are added based on the sample type and desired analysis.

- Heating: The sample-acid mixture is heated, often in a closed system to prevent loss of volatile substances.

- Cooling and Filtration: Once the reaction is complete, the mixture is cooled and filtered to obtain a clear solution for analysis.

Applications and Benefits

Wet digestion is essential in fields like biomedicine, agriculture, and food safety. Its advantages include:

- Comprehensive Decomposition: It can effectively break down almost all forms of organic matter.

- Suitability for Volatile Elements: It allows for the analysis of volatile elements that might be lost in dry ashing.

- Adaptability: The method can be adapted to different sample types by varying the acid mixtures and digestion conditions.

Common Challenges

However, wet digestion also faces several issues:

- Safety Risks: Handling strong acids at high temperatures increases the risk of accidents.

- Complex Waste Management: The chemical waste generated needs careful disposal to avoid environmental harm.

- Equipment Cost: The need for specialized, often expensive, equipment to handle the corrosive and pressurized environment.

Comparing Techniques

Efficiency and Accuracy

Both techniques offer high levels of accuracy in elemental analysis, but their efficiency can vary. Wet digestion is often quicker than dry ashing due to faster chemical reactions, albeit requiring more meticulous setup and cleanup.

Time Consumption

Dry ashing is more time-consuming, often requiring several hours to overnight heating, whereas wet digestion can typically be completed in less than a day, including preparation and clean-up time.

Safety Considerations

Wet digestion poses greater safety risks due to the use of corrosive acids and high pressure. In contrast, dry ashing primarily involves managing high temperatures, with fewer chemical hazards.

Cost Analysis

The initial investment in equipment for wet digestion is typically higher than for dry ashing. However, the ongoing costs of chemicals and waste disposal can make wet digestion more expensive over time. Dry ashing, with minimal chemical use, often presents a lower cost for long-term operations.

Equipment and Tools

For Dry Ashing

Dry ashing requires specific equipment to ensure the process is conducted safely and effectively:

- Muffle Furnace: Central to the dry ashing process, used to maintain high temperatures safely.

- Crucibles: Made from materials such as porcelain or quartz, these containers withstand high temperatures and contain the sample during ashing.

- Desiccators: Used to cool the ashed samples in a moisture-free environment to avoid contamination.

- Balances: High-precision balances are essential for measuring residues to ensure accuracy in subsequent analyses.

For Wet Digestion

Wet digestion also relies on specialized tools and equipment to handle corrosive substances and high pressures:

- Hot Plates and Heating Blocks: These provide controlled heating necessary for the digestion process.

- Digestion Vessels: Often made from resistant materials like Teflon to withstand strong acids and high temperatures.

- Fume Hoods: Essential for safely venting fumes produced during digestion.

- pH Meters and Conductivity Meters: Used for measuring the acidity and ionic strength of solutions post-digestion.

Choosing the Right Method

Factors to Consider

Selecting between dry ashing and wet digestion involves several key considerations:

- Sample Composition: Some materials are unsuitable for high temperatures or corrosive chemicals.

- Elemental Analysis Goals: Certain elements are better recovered by one method over the other.

- Available Resources: Equipment and safety facilities can influence the choice of method.

- Regulatory Requirements: Some industries have specific guidelines on how samples should be prepared.

Industry Recommendations

Industry experts often recommend:

- Environmental Samples: Prefer wet digestion for better recovery of volatile heavy metals.

- Food and Agricultural Products: Dry ashing is favored for its ability to process large volumes and its simplicity in handling common minerals.

Case Studies

Example in Environmental Science

In a study examining soil contamination:

- Sample Preparation: Contaminated soil samples underwent wet digestion.

- Analysis: Metals such as lead and arsenic were quantified.

- Outcome: Revealed elevated levels of heavy metals close to industrial sites, informing cleanup efforts.

Example in Food Safety

A food safety laboratory analyzed rice for arsenic content using dry ashing:

- Process: Rice samples were ashed to remove organic matter.

- Detection: Arsenic levels were measured and compared against safety standards.

- Impact: Results informed guidelines on rice consumption and sourcing.

Future Trends

Technological Advancements

Emerging technologies are set to transform both dry ashing and wet digestion:

- Automated Systems: Enhance precision and reduce manual errors.

- Microwave-Assisted Digestion: Offers faster processing times and lower acid usage.

- Real-Time Analysis Integration: Facilitates immediate evaluation of digestion efficiency and completeness.

Research Directions

Ongoing research aims to improve sample preparation techniques:

- Greener Chemistry: Efforts to reduce the use of hazardous chemicals in sample digestion.

- High-Throughput Techniques: Development of methods that can process multiple samples simultaneously, increasing lab efficiency.

- Element-Specific Optimization: Creating tailored protocols for the accurate detection of specific elements, particularly those prone to volatility or loss during conventional preparations.

Frequently Asked Questions

What is Dry Ashing?

Dry ashing is a method used primarily in analytical chemistry where samples are incinerated at high temperatures, causing organic matter to oxidize, leaving behind a residue of inorganic ash. This technique is useful for samples with high mineral content.

How does Wet Digestion work?

Wet digestion involves adding a combination of acids to a sample and heating it, typically in a closed system. This process accelerates the breakdown of organic materials, allowing for the analysis of dissolved metals and minerals.

When to choose Dry Ashing over Wet Digestion?

Choose dry ashing when dealing with samples that are heat stable and require the analysis of solid residues. It’s ideal for materials such as ceramics and metals where volatile elements are not of interest.

What are the safety concerns with Wet Digestion?

Wet digestion can be hazardous due to the use of strong acids and the potential for pressure build-up in closed systems. Proper laboratory safety measures, including the use of fume hoods and pressure-resistant vessels, are crucial.

Can Dry Ashing and Wet Digestion be used together?

Yes, these methods can be complementary. For comprehensive elemental analysis, some laboratories use both techniques on different fractions of the same sample to maximize data accuracy and completeness.

Conclusion

The choice between dry ashing and wet digestion hinges on numerous factors, including the nature of the sample, the elements of interest, and the specific requirements of the elemental analysis. Each method offers distinct advantages and entails particular considerations that must be weighed carefully.

Ultimately, the decision to use dry ashing or wet digestion should align with the analytical goals, resource availability, and safety protocols of the research facility. By selecting the appropriate method, laboratories can ensure accurate, reliable results in their elemental analyses, contributing valuable insights across various scientific domains.