In the realm of chemical synthesis, precipitation techniques are pivotal for separating and purifying chemicals. Coprecipitation and post precipitation are two fundamental methods used extensively across various scientific and industrial domains. Each technique possesses unique characteristics and applications, shaped by their underlying principles and methodologies.

Coprecipitation involves the simultaneous precipitation of a primary substance and one or more co-contaminants within a solution, often used to purify or refine materials. In contrast, post precipitation refers to the sequential precipitation of different substances within the same solution, primarily focused on enhancing purity after an initial precipitation process has occurred. This distinction is crucial for optimizing chemical synthesis and achieving desired material properties.

These techniques not only serve to enhance material purity and functionality but also play a critical role in cost management and process efficiency in industrial settings. Understanding their differences and applications can significantly impact the choice of method in both research and commercial production settings.

Basic Concepts

Definition of Precipitation

Precipitation in chemistry is the process by which a solid forms in a solution during a chemical reaction. Typically, this solid is insoluble or less soluble in the solvent compared to the reactants. When the concentration of one or more reactants reaches a critical level—known as the solubility limit—a solid, known as a precipitate, forms and separates from the solution.

Key Terms and Principles

Solubility: The ability of a substance to dissolve in a solvent.

Supersaturation: A state of a solution that contains more of the dissolved material than could be dissolved by the solvent under normal circumstances.

Nucleation: The initial process that occurs in the formation of a precipitate where the ions in solution start to gather into clusters, leading to the formation of tiny solids.

Growth: The subsequent increase in size of these tiny solids through the addition of more ions from the solution.

Coprecipitation Explained

What is Coprecipitation?

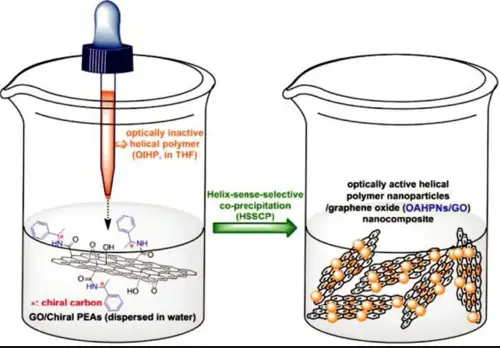

Coprecipitation is a process where a substance crystallizes from a solution and carries along with it impurities or other substances, which are also crystallized but would not precipitate on their own under the existing conditions.

Mechanisms of Coprecipitation

There are mainly two mechanisms in coprecipitation: adsorption and inclusion. In adsorption, impurities attach to the surface of the growing crystals. Inclusion, on the other hand, involves impurities being trapped within the crystal lattice.

Applications in Industry

Coprecipitation is widely used in industries such as:

- Water treatment: to remove contaminants.

- Pharmaceuticals: for purification of compounds.

- Mining: to recover precious metals from ores.

Post Precipitation Overview

Definition of Post Precipitation

Post precipitation is a refining process where a precipitate is formed and then, through additional reactions or adjustments in the chemical environment, further substances precipitate out of the solution. This can enhance the purity of the primary precipitate.

Process Characteristics

Post precipitation often involves altering the pH or introducing additional reagents to induce the precipitation of the remaining dissolved substances.

Industrial Uses

- Chemical manufacturing: to refine end products.

- Environmental management: to remove or recover pollutants.

- Material science: in the synthesis of advanced materials with high purity.

Comparative Analysis

Process Timing and Control

Coprecipitation typically occurs rapidly and does not offer much control over the purity of the precipitate, as the primary and secondary substances precipitate together. Post precipitation, however, can be timed and controlled more precisely since it involves additional steps after the initial precipitation.

Material Purity and Composition

The purity of materials obtained through post precipitation is generally higher than that achieved by coprecipitation. This is because the sequential nature of post precipitation allows for the targeted removal of specific impurities.

Cost-effectiveness and Scalability

While coprecipitation is cost-effective for bulk processes due to its simplicity and speed, post precipitation requires more resources and time, which can increase costs. However, the scalability of post precipitation processes is favorable in industries where high purity is essential, justifying the additional expense.

Advantages of Each Method

Benefits of Coprecipitation

Coprecipitation offers several advantages that make it appealing for various applications:

- Simplicity and Speed: The process is straightforward, allowing for quick and efficient precipitation without the need for complex equipment or conditions.

- Cost-Effectiveness: Due to its simplicity, coprecipitation is less expensive compared to other purification techniques. This makes it ideal for large-scale operations where budget constraints are a concern.

- Enhanced Yield: Coprecipitation can increase the yield of the target substance by co-precipitating it with other substances, thus maximizing the extraction from the solution.

Benefits of Post Precipitation

Post precipitation also presents unique advantages:

- High Purity Levels: This method can achieve higher purity in the final product, as it allows for the selective precipitation of impurities after the initial process.

- Flexibility: Post precipitation provides the ability to adjust process parameters after the first precipitation, offering greater control over the final product’s composition and purity.

- Targeted Purification: Specific impurities can be targeted and removed, which is crucial in applications requiring high precision, such as pharmaceuticals and fine chemicals.

Limitations and Challenges

Coprecipitation Issues

While beneficial, coprecipitation has its limitations:

- Contaminant Co-precipitation: Impurities may precipitate along with the target compound, leading to potential contamination if not controlled properly.

- Limited Control Over Purity: The simultaneous precipitation of materials can limit the ability to achieve high purity, requiring further purification steps.

- Dependency on Conditions: The efficiency of coprecipitation can be highly dependent on the pH, temperature, and other environmental conditions, making it less predictable.

Post Precipitation Drawbacks

Post precipitation also faces several challenges:

- Higher Costs: The need for additional reagents and possibly longer processing times can increase the overall costs of the method.

- Complexity: This method may require more sophisticated equipment and skilled personnel to manage the additional steps involved.

- Scale Limitations: Scaling up post precipitation processes can be challenging due to the precise control needed over the conditions during each stage of precipitation.

Case Studies

Real-world Applications

Water Treatment: In water treatment facilities, coprecipitation is used to remove heavy metals and other pollutants from water. For instance, arsenic and lead are commonly removed through coprecipitation with iron oxides.

Pharmaceuticals: Post precipitation plays a critical role in the pharmaceutical industry to ensure that drugs meet purity requirements. This method is used to refine active pharmaceutical ingredients, removing unwanted by-products after initial synthesis.

Impact on Product Outcomes

Material Science: In the field of material science, coprecipitation has enabled the development of novel composite materials with unique properties, such as improved magnetic materials for data storage applications.

Chemical Industry: In the chemical industry, the use of post precipitation has led to the production of highly pure chemicals that are essential for the synthesis of specialty products, including high-performance polymers and fine chemicals.

Future Trends

Innovations in Precipitation Methods

Ongoing research is focused on enhancing both coprecipitation and post precipitation techniques. Innovations include the development of new reagents that can improve the selectivity and efficiency of these processes. Additionally, advances in monitoring and control technology are making it possible to more precisely control the conditions under which precipitation occurs, leading to better outcomes.

Predictions for Industrial Adoption

The future will likely see increased adoption of advanced precipitation techniques in industries such as renewable energy, where material purity is critical for the performance of devices like solar cells and batteries. Furthermore, the ongoing push for more sustainable manufacturing processes could see these methods being adapted to minimize waste and reduce the environmental impact of industrial activities.

Frequently Asked Questions

What is Coprecipitation?

Coprecipitation is a method where impurities are precipitated alongside a target compound during the formation of a precipitate. This technique is often employed to isolate or purify substances in a solution where the primary and secondary precipitates form simultaneously, enhancing the efficiency of the purification process.

How does Post Precipitation work?

Post precipitation occurs after an initial precipitate has formed. This method involves inducing a secondary precipitation process to refine the purity of the precipitate or to separate different components that were not removed during the first precipitation step. It is commonly used to achieve higher levels of purity in chemical syntheses.

Why choose Coprecipitation over Post Precipitation?

Choosing between coprecipitation and post precipitation often depends on the specific requirements of the process, such as the desired purity, the nature of the impurities, and cost considerations. Coprecipitation is typically faster and less costly but may offer less control over purity compared to post precipitation, which provides finer purification at potentially higher costs.

Can Coprecipitation affect material properties?

Yes, coprecipitation can significantly affect the properties of the materials produced, including their solubility, magnetic properties, and structural integrity. This impact makes it a critical consideration in the formulation and design of materials, especially in industries like pharmaceuticals and materials engineering.

Conclusion

In summary, coprecipitation and post precipitation are essential techniques in chemical processing, each with its strategic advantages and limitations. Understanding these methods facilitates better decision-making in selecting the appropriate technique based on specific industrial needs and material characteristics.

The future of chemical manufacturing and research will continue to rely heavily on these precipitation techniques. Innovations and advancements in these areas are likely to further refine their efficiency and expand their applications, underscoring their importance in scientific and industrial advancements.