In the realm of liquid processing, achieving the desired level of clarity and purity is crucial across various industries, from food and beverage to pharmaceuticals. This necessity has led to the development and application of two fundamental processes: clarification and filtration. Both methods are pivotal in removing particulate matter and ensuring the liquid product meets quality and safety standards.

Clarification and filtration are techniques used to separate solids from liquids, but they operate on different principles and are suitable for varying types of suspensions. Clarification typically involves the settling of particles or the use of agents to facilitate particle aggregation, making them easier to remove. Filtration, on the other hand, employs a barrier or media to physically separate the solids from the liquids based on particle size.

The choice between clarification and filtration depends on several factors, including the nature of the liquid, the type of contaminants, and the desired final product quality. While clarification is often used for larger volumes with lower levels of particulate matter, filtration is favored when dealing with finer particles or when a higher purity level is required. Each process has its own set of equipment, operational principles, and application areas, reflecting the diversity of challenges faced in liquid processing.

Basic Concepts

Clarification Explained

Definition and Purpose

Clarification is a process aimed at removing suspended solids from a liquid to enhance its clarity. This process does not necessarily result in a sterile product but significantly reduces the turbidity, making the liquid more transparent. The primary purpose of clarification is to prepare liquids for further processing, improving product quality and stability.

Common Applications

Clarification finds its applications across various industries. In the food and beverage industry, it’s crucial for wine and beer making, where clarity is a quality attribute. Water treatment also employs clarification to remove contaminants before filtration steps. Additionally, the pharmaceutical industry uses it to clear up solutions and extracts during the manufacturing process.

Filtration Basics

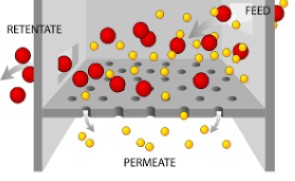

Definition and Mechanism

Filtration involves the physical separation of solids from liquids by passing the mixture through a filter medium that allows only the liquid to pass while trapping the solids. This process can achieve a higher level of purity and clarity compared to clarification, as it can remove much smaller particles.

Key Uses

Filtration is essential in providing safe drinking water, removing harmful bacteria and other microorganisms. In the chemical industry, it’s used to purify raw materials and final products. Air filtration is another critical application, ensuring clean and safe indoor air quality in residential, commercial, and industrial settings.

Process Comparison

Techniques and Equipment

Equipment Used in Clarification

Clarification equipment varies from simple settling tanks, where gravity assists in sedimentation, to more complex systems like centrifuges and flocculators. Centrifuges rapidly spin the liquid, using centrifugal force to separate solids. Flocculators add chemicals to promote particle aggregation, making them easier to remove.

Filtration Tools and Materials

Filtration employs a range of tools and materials, including paper filters, membranes, sand beds, and activated carbon. The choice of filter media depends on the application and the size of the particles to be removed. Reverse osmosis systems represent advanced filtration technology, capable of removing very fine particles and dissolved substances.

Operational Principles

How Clarification Works

Clarification typically involves the following steps:

- Addition of coagulants to bind small particles into larger aggregates.

- Sedimentation, where the aggregated particles settle to the bottom due to gravity.

- Removal of the clear liquid from the top.

Filtration Process Details

Filtration involves:

- Passing the liquid through a filter medium.

- Trapping and retaining the solids on the filter.

- Collecting the filtered liquid from the other side.

Key Differences

Methodology Contrast

Clarification is a physical process enhanced by chemical additives, focusing on the aggregation and removal of larger particles. Filtration, on the other hand, is a mechanical process that physically blocks particles, capable of removing much finer particles from the liquid.

Role of Additives in Clarification

Additives like coagulants and flocculants play a critical role in clarification, improving the efficiency of particle removal. These substances help in forming larger, more settleable particles from colloidal suspensions, which are otherwise difficult to remove.

Efficiency and Use Cases

Situational Efficiency of Both Processes

The efficiency of clarification and filtration depends on the type of liquid and the nature of impurities. Clarification is more efficient for liquids with larger, settleable particles, while filtration is suited for finer particles or when a higher degree of purity is required.

Choosing Between Clarification and Filtration

The choice between clarification and filtration is guided by factors such as:

- Desired purity level

- Volume of liquid to be processed

- Nature of the solids to be removed

Quality and Outcome

Impact on Liquid Quality

Filtration can achieve a higher level of liquid quality in terms of purity and clarity, suitable for applications requiring stringent quality standards. Clarification, while improving clarity, may not remove all microorganisms or fine particles.

Residuals and Waste Considerations

Both processes generate waste in the form of removed solids. However, the nature and quantity of the waste differ, with filtration potentially producing more concentrated waste due to the smaller size of the particles removed. Managing these residuals responsibly is crucial to minimize environmental impact.

Industry Applications

Food and Beverage

Role in Wine and Beer Production

In the wine and beer industries, clarity and stability are paramount for both aesthetics and taste. Clarification processes like cold stabilization, fining, and filtration are vital steps. They remove yeast, proteins, and other haze-forming particles that can affect the final product’s appearance and shelf life. Filtration, particularly, is used to achieve the crystal-clear quality expected by consumers, using fine filters to polish the beverage before bottling.

Water Treatment for Beverages

Water is the cornerstone of the beverage industry, not just as a product but as a critical ingredient. The treatment of water through filtration systems like reverse osmosis ensures that it meets strict purity standards. These systems can remove dissolved salts, organic compounds, and microorganisms, ensuring the water’s flavor and quality align with production needs.

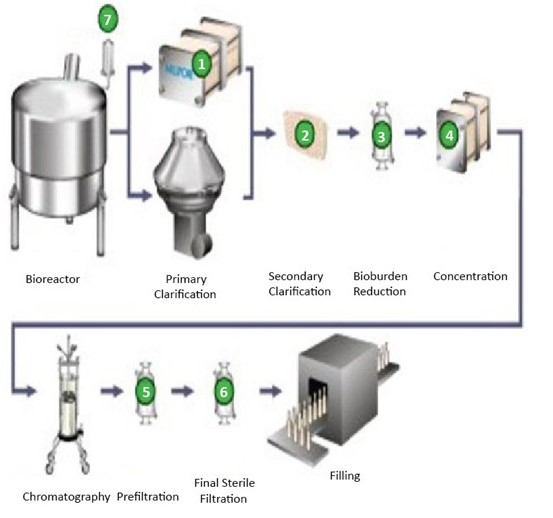

Pharmaceutical and Biotech

Ensuring Drug Purity

In the pharmaceutical sector, the stakes for purity are high. Filtration plays a crucial role in ensuring that drugs are free from particulate contamination and microbial presence. Processes like sterile filtration are non-negotiable steps in the production of injectables and sensitive formulations, safeguarding patient safety and drug efficacy.

Application in Bioprocesses

Biotechnological applications often require both clarification and filtration at different stages. For instance, the production of biologics involves clarification to remove cells and larger debris from culture broths, followed by fine filtration to purify the desired proteins or molecules. These steps are critical in maintaining the integrity and activity of bioproducts.

Environmental Impact

Wastewater Treatment Methods

Wastewater treatment is a vital environmental application of clarification and filtration. Clarification is used to remove large particulates and some organic loads from wastewater, while filtration can tackle finer particles, pathogens, and even dissolved pollutants in advanced treatments. Together, they play an essential role in recycling water and reducing the burden on natural water bodies.

Reducing Industrial Effluents

Minimizing industrial effluents is a growing concern, with both processes aiding in this endeavor. By treating wastewater before discharge, industries can significantly reduce their environmental footprint. Innovations in both clarification and filtration technologies are making it possible to recover more materials and recycle water within industrial processes, promoting sustainability.

Advancements and Innovations

Recent Developments

Technological Advances in Filtration

Filtration technology has seen significant advancements, with developments in membrane technology leading the charge. Nanofiltration and ultrafiltration membranes can now target specific molecules, offering precise separations. This specificity is crucial in industries like pharmaceuticals, where product purity is non-negotiable.

Innovations in Clarification Techniques

Clarification has also benefited from innovation, with new flocculants and coagulants designed for more efficient particle aggregation. Moreover, the advent of automated sedimentation analysis and monitoring tools allows for real-time process optimization, enhancing the efficiency of clarification processes.

Future Prospects

Predicted Trends in Liquid Processing

The future of liquid processing sees an increasing shift towards sustainability and efficiency. Technologies that reduce energy consumption, minimize waste, and recover valuable by-products are in high demand. The development of more efficient, selective, and adaptable filtration and clarification systems will be key to meeting these industry needs.

Potential for Sustainable Practices

The potential for sustainable practices in liquid processing is vast. Innovations like biodegradable filter media and energy-efficient process designs promise to reduce the environmental impact of these essential processes. Moreover, the recovery of materials from waste streams represents a significant opportunity for resource conservation and reuse.

Practical Insights

Selection Criteria

Factors Influencing Process Choice

The selection between clarification and filtration—or a combination of both—depends on several factors:

- Desired purity level and quality of the final product

- Nature and size of the particles to be removed

- Volume of liquid to be processed

- Economic considerations, including equipment and operation costs

Cost, Scale, and Material Considerations

Choosing the right process involves a careful analysis of cost, scale, and material. Large-scale operations may favor clarification for its lower operating costs, while high-value or small-volume products might justify the higher costs of advanced filtration methods.

Troubleshooting Tips

Common Challenges and Solutions

Both processes can face challenges like clogging, efficiency drops, and inconsistent results. Regular maintenance, proper feed pre-treatment, and the selection of appropriate process parameters can mitigate these issues.

Maintenance and Optimization Strategies

Effective maintenance and optimization strategies include:

- Routine cleaning and inspection of equipment

- Process monitoring for early detection of issues

- Optimization of operational parameters based on ongoing performance data

FAQs

What is the main difference between clarification and filtration?

The main difference lies in their operational approach and the size of the particles they target. Clarification is designed for the removal of larger particles and often employs chemical agents to aggregate particles for easier removal. Filtration, however, physically separates particles from the liquid using a filter medium, making it suitable for smaller particles.

When should I choose clarification over filtration?

Clarification is best suited for large volumes of liquid with relatively low levels of particulate matter. It is ideal for applications where the primary goal is to remove larger particles or when the liquid itself can tolerate some degree of turbidity. For instance, in the initial stages of wine production, clarification is often preferred.

Can filtration achieve the same results as clarification?

While both processes aim to remove unwanted particles from liquids, filtration can generally achieve a higher level of purity, particularly with fine particles. It is the preferred method in applications requiring high clarity and purity, such as in pharmaceutical manufacturing and drinking water treatment.

Is one process more cost-effective than the other?

The cost-effectiveness of clarification versus filtration varies based on the application, volume of liquid to be processed, and the level of purity required. Clarification can be more cost-effective for large-scale operations with less stringent clarity requirements, while filtration may incur higher initial costs but is necessary for finer separations.

Conclusion

In conclusion, both clarification and filtration serve essential roles in liquid processing, each with its unique set of advantages, operational principles, and application areas. The choice between these two processes depends on the specific requirements of the task at hand, including the nature of the liquid, the types of impurities present, and the desired outcome in terms of clarity and purity.

Understanding the distinct mechanisms and applications of clarification and filtration is vital for professionals across industries. By selecting the appropriate method, they can ensure the quality and safety of their products, meet regulatory standards, and achieve operational efficiency. As advancements in technology continue to evolve, the capabilities and applications of these processes are likely to expand, further enhancing their importance in liquid processing.