Composite materials are revolutionizing various industries by offering unique advantages over traditional materials like metal and wood. Among these advanced composites, Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) stand out due to their exceptional properties and versatile applications. Each material brings distinct characteristics to the table, influencing their suitability for different uses.

The primary difference between CFRP and GFRP lies in their strength and cost. CFRP is renowned for its outstanding strength-to-weight ratio and stiffness, making it a preferred choice in aerospace and sports equipment. On the other hand, GFRP offers a more cost-effective solution with good strength and is extensively used in construction and automotive industries. These contrasting features dictate their preference in various applications, impacting industries from aviation to building.

Exploring these materials reveals a deeper insight into their composition, manufacturing processes, and performance metrics. While CFRP consists of carbon fiber and a polymer matrix, GFRP is made from fiberglass and a similar matrix. This fundamental variance in fiber type affects everything from their mechanical properties to their environmental impact, guiding industry choice and innovation.

CFRP Overview

Definition of CFRP

Carbon Fiber Reinforced Polymer (CFRP) is an advanced composite material made primarily from carbon fiber and a polymer resin. This material is highly regarded for its exceptional strength and lightweight properties. CFRP integrates the high stiffness and strength of carbon fiber with the versatility of various resins, resulting in a material that can be both incredibly durable and extraordinarily light.

Key Properties

CFRP exhibits several key properties that make it a standout choice in high-performance applications:

- High Strength-to-Weight Ratio: CFRP provides superior strength without adding significant weight, making it ideal for applications where every kilogram counts.

- High Stiffness: The stiffness of CFRP is significantly higher than many metals, which is critical in aerospace and automotive fields.

- Corrosion Resistance: Unlike metals, CFRP does not corrode, offering longer life in harsh environments.

- Fatigue Resistance: CFRP structures are known for their durability and resistance to fatigue, enhancing their lifespan under cyclical loads.

Common Uses

CFRP is extensively used across various industries due to these properties. Common applications include:

- Aerospace: Used in the manufacture of aircraft structures, where its strength and lightweight are crucial.

- Automotive: Employed in high-performance vehicles not just for structural parts but also in the design of aesthetic elements.

- Sports Equipment: From bicycles to golf clubs and fishing rods, CFRP is used to enhance performance and durability.

GFRP Overview

Definition of GFRP

Glass Fiber Reinforced Polymer (GFRP) consists of fiberglass, a type of glass that is extruded into thin strands, woven into a fabric, and then set within a polymer matrix. GFRP is praised for its strength, flexibility, and cost effectiveness.

Key Properties

GFRP also has several important properties:

- Good Tensile Strength: While not as strong as CFRP, GFRP still provides sufficient strength for many applications.

- Flexibility: GFRP is more flexible than CFRP, which can be advantageous in certain manufacturing applications.

- Non-Conductive: GFRP is non-conductive, making it safe for use in electrical insulation applications.

- Chemical Resistance: It offers good resistance against various chemicals, a critical factor in chemical processing industries.

Common Uses

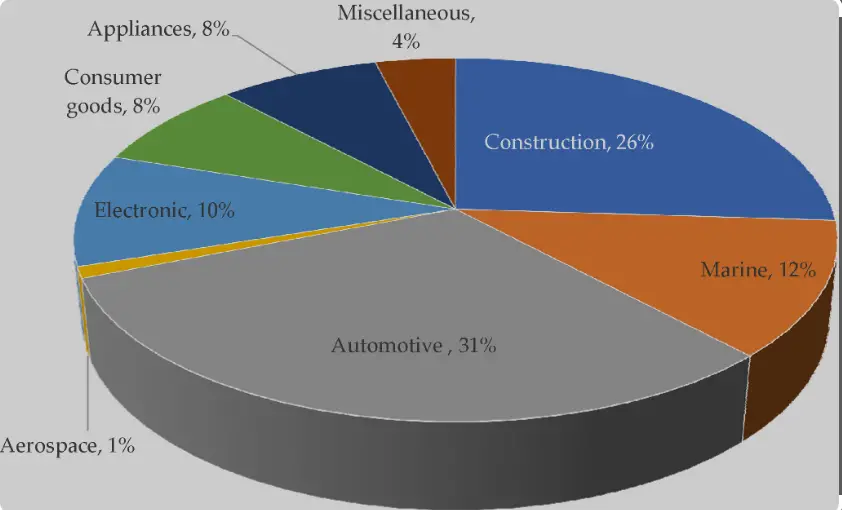

Due to its versatility and lower cost compared to CFRP, GFRP finds usage in a variety of sectors:

- Building and Construction: Used in panels, pipes, and as reinforcing bars in concrete.

- Automotive: Components such as bumpers and body panels are often made from GFRP due to its moldability and robustness.

- Marine: Boats and other marine structures benefit from GFRP’s resistance to water and corrosion.

Material Composition

CFRP Components

The primary components of CFRP include:

- Carbon Fibers: These are typically made from polyacrylonitrile (PAN) and are known for their excellent strength and stiffness.

- Resin Matrix: Epoxy resin is the most common type used, acting as a binder that holds the fibers together and distributes loads among them.

GFRP Components

GFRP is composed of:

- Glass Fibers: These fibers are cheaper than carbon fibers and offer good tensile strength and flexibility.

- Polymer Matrix: Polyester or vinyl ester resins are commonly used with glass fibers to form the composite.

Manufacturing Processes

CFRP Production Techniques

CFRP can be manufactured through several processes, each suited to different end-uses:

- Lay-Up Process: Involves laying carbon fibers in a mold and applying resin either manually or through an infusion process.

- Pultrusion: Fibers are pulled through a resin bath and then through a heated die to cure the resin, creating continuous lengths of CFRP.

GFRP Production Techniques

GFRP manufacturing often uses similar techniques:

- Hand Lay-Up: Simplest form of open molding where fibers are placed in the mold and resin is applied by hand.

- Spray-Up: A chopper gun is used to spray resin and short strands of fibers onto the mold, useful for large or complex shapes.

Performance Comparison

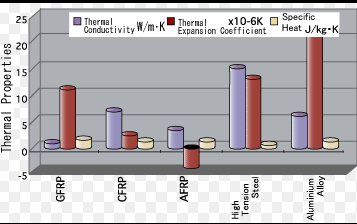

Strength and Durability

CFRP offers higher strength and durability compared to GFRP, making it suitable for high-load applications such as in aerospace and automotive sectors. GFRP, while not as strong, still holds up well under many conditions and is favored in non-critical structures.

Weight and Density

CFRP is significantly lighter than GFRP, which is a critical factor in its use in performance-sensitive applications.

Thermal Conductivity

CFRP generally exhibits lower thermal conductivity compared to GFRP, providing better insulation properties in some applications. However, the specific use case dictates the choice between CFRP and GFRP based on thermal performance.

Cost Analysis

Material Costs

The cost of materials is a crucial factor when choosing between CFRP and GFRP. CFRP is typically more expensive due to the high cost of carbon fiber, which is produced from acrylonitrile, a petroleum-derived product requiring complex processing. On the other hand, GFRP uses glass fibers, which are cheaper and derived from simpler materials such as silica sand. The difference in material costs significantly impacts the final product cost, making GFRP a more budget-friendly option for many industries.

Manufacturing Costs

Manufacturing costs for CFRP and GFRP vary based on the complexity of the manufacturing process and the scale of production.

- CFRP: The production process often involves advanced techniques like autoclave curing, which require significant energy and specialized equipment. This adds to the cost.

- GFRP: Typically involves simpler manufacturing processes like hand lay-up or spray-up, which are less expensive and require less specialized equipment.

Environmental Impact

Lifecycle Analysis

Both CFRP and GFRP have unique environmental footprints that need consideration:

- CFRP: While offering benefits like reduced weight and increased fuel efficiency in vehicles and aircraft, CFRP’s production is energy-intensive and involves significant CO2 emissions.

- GFRP: Although less energy-intensive to produce, the use of non-renewable resources like silica and the emissions from polyester resin production impact its environmental footprint.

Recyclability and Sustainability

Recycling of composite materials like CFRP and GFRP presents challenges due to the difficulty in separating the fiber from the resin.

- CFRP: Newer recycling processes are being developed, such as pyrolysis and mechanical grinding, but are not yet widely implemented.

- GFRP: Typically, GFRP can be ground down and used as a filler material, though this down-cycling does not fully exploit the material’s original value.

Industry Applications

Aerospace and Aviation

CFRP is extensively used in the aerospace sector due to its high strength-to-weight ratio, which significantly reduces the weight of aircraft, resulting in better fuel efficiency and performance. Components like wings, fuselage, and internal elements are increasingly made from CFRP.

Automotive Sector

Both CFRP and GFRP have found their roles in the automotive industry.

- CFRP: Used in high-end sports cars for body parts, frames, and interiors to reduce weight and increase speed.

- GFRP: More common in everyday consumer vehicles for non-load-bearing components such as bumpers and dashboards.

Building and Construction

GFRP is becoming a popular choice in construction due to its corrosion resistance and strength. It is used for reinforcing bars in concrete, roofing, and facade panels where metal components would corrode or add undesirable weight.

Advantages and Limitations

Benefits of CFRP

- Lightweight and Strong: Ideal for applications where weight savings are critical.

- Durability: Highly resistant to fatigue and environmental factors.

Benefits of GFRP

- Cost-Effective: Provides a good balance of cost and performance for less critical applications.

- Versatile: Easy to mold and adaptable to complex shapes.

Limitations of Both Materials

While CFRP and GFRP offer significant benefits, they also have limitations:

- Cost: Especially for CFRP, the high cost can be a barrier.

- Recycling Issues: Challenges in recycling remain a significant concern for environmental sustainability.

Future Trends

Innovations in Material Science

Ongoing research in material science aims to enhance the properties of CFRP and GFRP and overcome existing limitations. Innovations include developing new resin systems that cure faster or at lower temperatures, and fibers that offer greater performance or are derived from renewable sources.

Emerging Market Demands

As the demand for more sustainable and efficient materials grows, both CFRP and GFRP are expected to evolve. The aerospace and automotive industries, in particular, are pushing for materials that offer higher performance with lower environmental impact. The building and construction industry is also seeking more durable and maintenance-free materials.

Frequently Asked Questions

What is CFRP?

Carbon Fiber Reinforced Polymer (CFRP) is a composite material known for its high strength and lightweight properties. It consists of carbon fiber, which provides the strength, embedded in a polymer matrix that binds the fibers together and transfers loads between them.

What is GFRP?

Glass Fiber Reinforced Polymer (GFRP) is made from fiberglass, which is woven into a fabric then bonded together with a polymer resin. GFRP is favored for its flexibility, cost effectiveness, and resistance to corrosion.

How do CFRP and GFRP differ in cost?

CFRP is generally more expensive than GFRP due to the higher cost of carbon fiber compared to glass fiber. This makes GFRP a more budget-friendly option in industries where extreme strength is not a requirement.

Where are CFRP and GFRP commonly used?

CFRP is commonly used in aerospace, automotive, and sporting goods due to its high strength and stiffness. GFRP is often used in building, construction, and automotive industries where a balance between cost and performance is necessary.

What are the environmental impacts of CFRP and GFRP?

Both materials pose challenges in recycling due to the thermosetting polymers used in their matrices. However, research into more sustainable production and recycling processes is ongoing to mitigate their environmental impact.

Conclusion

In conclusion, CFRP and GFRP are cornerstone materials in the realm of modern composites, each playing crucial roles in advancing the capabilities of their respective industries. CFRP, with its superior strength and lightweight, is pivotal in high-performance applications requiring the utmost efficiency. Meanwhile, GFRP continues to be indispensable in sectors seeking a balance between cost and functionality.

As industries evolve and environmental considerations become more pressing, the development and application of these materials will undoubtedly adapt. The ongoing research and innovation in composite technology will further refine their properties and expand their uses, cementing their status as materials of the future.