Chemical reagents play a critical role in the world of chemistry, serving as the backbone of numerous industrial and laboratory processes. Each reagent, depending on its nature and purpose, interacts differently within reactions, leading to varied outcomes. Distinguishing between catalytic and stoichiometric reagents is fundamental for chemists and engineers alike, as each type brings unique properties and applications to the table.

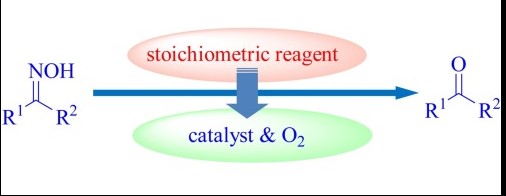

Catalytic reagents are used in minimal quantities and primarily function to accelerate reaction rates without being consumed by the reaction itself. On the other hand, stoichiometric reagents are consumed in the reaction in exact proportions as required by the stoichiometric ratio of the reactants. This essential difference affects both the efficiency and cost of chemical processes.

While catalytic reagents often contribute to more sustainable and cost-effective processes by minimizing waste and energy consumption, stoichiometric reagents offer simplicity and precise control over reaction products. Each type of reagent has its specific advantages and limitations, which are exploited differently depending on the desired chemical process and outcome.

Basics of Reagents

Definition of Reagents

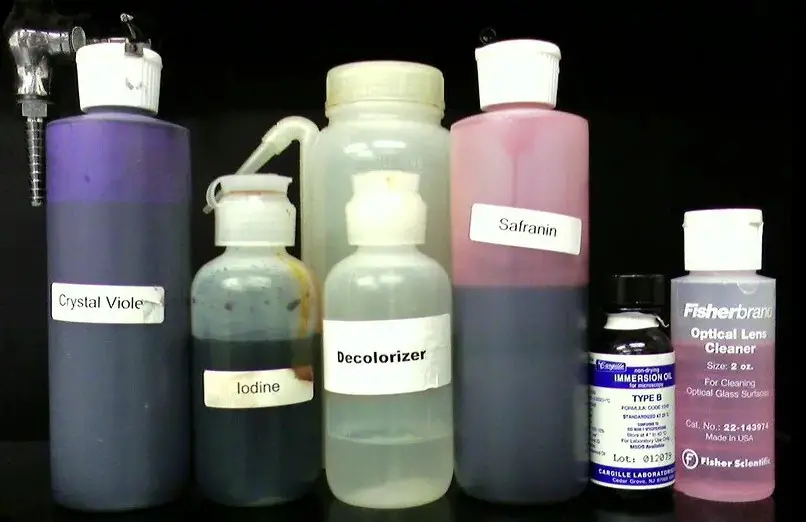

In chemistry, reagents are substances or compounds added to a system to cause a chemical reaction, or to see if a reaction occurs. These substances are essential in both laboratory experiments and industrial processes, playing pivotal roles as reactants, catalysts, or indicators.

Role in Chemical Reactions

Reagents are crucial for initiating and driving chemical reactions. They interact with other substances, altering their chemical structure to produce desired products. Their roles vary from acting as primary reactants that directly participate and are consumed in reactions, to catalysts which help the reaction proceed faster without being consumed.

What are Catalytic Reagents?

Definition and Characteristics

Catalytic reagents are substances that increase the rate of a chemical reaction without being consumed by the reaction itself. They function by providing an alternative pathway for the reaction with a lower activation energy. This characteristic allows for the reagent to be used repeatedly, influencing numerous reactions with a minimal amount.

Examples in Industry

Catalytic reagents have a wide array of applications in industries, particularly in:

- Petroleum refining: where catalysts are used to speed up the cracking process, converting heavy crude oil into gasoline, kerosene, and other petroleum products.

- Pharmaceuticals: catalytic methods are crucial for the synthesis of complex molecules, often providing cleaner and more efficient routes to drug production.

- Environmental technology: catalysts play a key role in reducing pollution, such as in catalytic converters that transform harmful car exhaust gases into less toxic substances.

What are Stoichiometric Reagents?

Definition and Characteristics

Stoichiometric reagents are used in exact proportions dictated by the reaction equation. They completely react and are entirely consumed in the reaction. This precise measurement ensures that the reactants transform into products without leaving any excess.

Common Applications

Stoichiometric reagents are fundamental in:

- Material synthesis: ensuring that products are formed with precise chemical compositions.

- Analytical chemistry: where they are used in titration to determine the concentration of a known reactant.

- Educational demonstrations: to teach the principles of chemical reactions and balancing equations.

Key Differences

Quantity Required

- Catalytic reagents are used in much smaller quantities compared to stoichiometric reagents.

- Stoichiometric reagents are required in amounts exactly matching the stoichiometric ratios in the reaction equation.

Reaction Mechanism

- Catalytic reagents work by providing a different pathway for the reaction with lower activation energy.

- Stoichiometric reagents participate directly and are consumed in the reaction based on the stoichiometric balance of the equation.

Cost Implications

- Using catalytic reagents tends to be more cost-effective over time as they are not consumed and can be used repetitively.

- Stoichiometric reagents may lead to higher operational costs due to the need for precise and often large quantities of chemicals.

Advantages of Catalytic Reagents

Less Material Use

Catalysts require minimal amounts to be effective, significantly reducing the need for raw materials. This not only lowers material costs but also reduces the handling and storage requirements.

Environmental Impact

The use of catalytic reagents often results in cleaner processes by minimizing waste and unwanted by-products. This supports industries in meeting environmental regulations and achieving sustainability goals.

Economic Benefits

The efficiency and durability of catalytic reagents provide substantial economic advantages. They enhance reaction speeds and turnover rates which, in turn, increase production capacity without additional costs for new reagents. This makes processes more economically viable and competitive in the market.

Advantages of Stoichiometric Reagents

Simplicity and Control

Stoichiometric reagents offer a straightforward approach to chemical reactions. By using these reagents in ratios precisely defined by the chemical equation, chemists can maintain strict control over the reaction process. This control is crucial in reactions where the exact proportion of reactants is necessary to achieve the desired product without any deviation.

Predictability and Yield

The predictability of stoichiometric reagents is one of their most valued aspects. When reagents are used in exact stoichiometric amounts, the yield of the product can be accurately predicted based on the initial quantities of reactants. This predictability is essential for industries that rely on consistent and uniform production outputs, such as pharmaceuticals and materials manufacturing.

Choosing the Right Reagent

Factors to Consider

Selecting the appropriate reagent for a chemical process involves several considerations:

- Reaction efficiency: How effectively does the reagent drive the reaction to completion?

- Cost-effectiveness: Is the reagent economically viable for the scale of the operation?

- Availability: Can the reagent be easily sourced and is it available in the required purity?

- Safety: What are the risks associated with handling and storing the reagent?

- Environmental impact: Does the use of the reagent pose any environmental risks?

Case Studies: Successful Applications

- Pharmaceuticals: In drug synthesis, the use of stoichiometric reagents has enabled the production of highly pure medications, as the exact control over reactants ensures the absence of unwanted byproducts.

- Material Science: In the fabrication of alloys and composites, stoichiometric reagents guarantee that the properties of the final products are consistent and meet specific performance criteria.

Challenges and Solutions

Common Issues with Catalytic Processes

While catalytic reagents are highly beneficial, they also come with challenges such as:

- Catalyst poisoning: Impurities in reactants can deactivate catalysts.

- Catalyst recovery: Retrieving catalysts from reaction mixtures can be complex and costly.

- Selectivity: Achieving high selectivity can be difficult in catalytic reactions, where unwanted side reactions might occur.

Overcoming Stoichiometric Limitations

Stoichiometric reagents, although precise, often result in large quantities of waste. Strategies to mitigate these issues include:

- Recycling processes: Developing methods to recover and reuse stoichiometric reagents.

- Process optimization: Refining reaction conditions to reduce excess reagents and waste production.

Future Trends

Research Developments

Ongoing research is focused on enhancing the efficiency and sustainability of both catalytic and stoichiometric reactions. Innovations include:

- Development of greener catalysts: Research into catalysts that are more environmentally friendly and capable of performing under milder conditions.

- Advanced stoichiometric methods: Techniques that allow for more precise control and lower waste production in stoichiometric reactions.

Potential Industry Changes

The chemical industry is poised for significant changes driven by advancements in reagent technology. Potential trends include:

- Increased automation: Automated systems for precise reagent handling and mixing, which reduce human error and improve reaction outcomes.

- Sustainability practices: Greater emphasis on sustainable practices will likely lead industries to favor reagents and processes that align with environmental goals.

Frequently Asked Questions

What are chemical reagents?

Chemical reagents are substances used in chemical reactions to either cause a reaction or indicate the presence of other substances. They can be catalysts, reactants, or substances that provide a suitable environment for a reaction to occur.

How do catalytic reagents work?

Catalytic reagents work by lowering the activation energy of a reaction, allowing it to proceed faster and more efficiently. They participate in the reaction but are not consumed by it, making them reusable in multiple reaction cycles.

What are the benefits of using catalytic reagents?

Catalytic reagents reduce the amount of material needed and decrease waste production, making processes more environmentally friendly and cost-effective. They are key in industries where high efficiency and sustainability are priorities.

Why use stoichiometric reagents?

Stoichiometric reagents are used when precise control over the composition of the reaction products is necessary. They ensure that reactions are complete, with all reactants being fully converted into products, which is crucial in the synthesis of pure substances.

Can catalytic reagents be used in all reactions?

Not all reactions are suitable for catalysis. The choice to use a catalytic reagent depends on the specific requirements of the reaction, including the desired speed, the feasibility of the catalyst in the reaction environment, and cost considerations.

Conclusion

The choice between catalytic and stoichiometric reagents hinges on the specific needs of a chemical process, including factors like cost, efficiency, control, and environmental impact. Catalytic reagents are preferred for their sustainability and efficiency, particularly in large-scale industrial applications, whereas stoichiometric reagents offer unmatched precision and reliability in product formation.

Understanding these differences not only enhances the effectiveness of chemical processes but also guides future innovations in chemical engineering and technology. As the field progresses, the development of new reagents and methods will continue to revolutionize the efficiency and environmental impact of chemical industries worldwide.