Polymers are essential materials used in myriad applications from simple household products to complex biomedical devices. Their unique properties, derived from their molecular structure, make them versatile and indispensable in modern life. Branched and crosslinked polymers, two significant categories within the broad spectrum of polymeric materials, exhibit distinctive characteristics and functionalities.

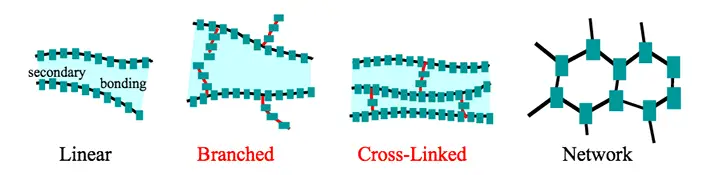

Branched polymers consist of a main chain with one or more subsidiary chains attached, which can affect their melting point, solubility, and strength. Crosslinked polymers, on the other hand, are structured with covalent bonds linking various polymer chains, enhancing their stability and heat resistance. The primary difference between these two lies in their molecular architecture which directly influences their physical and chemical properties.

While both types of polymers are crucial in their rights, their applications vary significantly based on their structural differences. From rubber tires, which rely on the robust nature of crosslinked polymers, to plastic bottles, which take advantage of the lightweight and moldable characteristics of branched polymers, the impact of these materials on daily and industrial applications is profound.

Polymer Basics

Definition and Significance

Polymers are large molecules composed of repeating structural units, typically connected by covalent chemical bonds. Modern society relies heavily on polymers, given their role in countless applications, from clothing and packaging to automotive and construction materials. The versatility of polymers stems from their ability to be molded into complex shapes and tailored for specific strength, durability, and elasticity.

General Properties

Polymers exhibit a range of physical properties that make them suitable for various applications:

- Thermal Stability: Ability to withstand high temperatures without degrading.

- Mechanical Strength: Resistance to deformation under stress.

- Chemical Resistance: Ability to resist degradation by various chemicals.

- Electric Insulation: Effectiveness in preventing the flow of electrical current, making polymers ideal for electronic applications.

Branched Polymers

Structure Explanation

Branched polymers are composed of a main chain with side chains branching off the backbone. This structure can be visualized as a tree with branches spreading out from the main trunk. The branching can occur randomly or at regular intervals along the main chain.

Common Types and Uses

- Low-Density Polyethylene (LDPE): Used for plastic bags and films due to its flexibility.

- High-Density Polyethylene (HDPE): Utilized in the production of bottles and piping due to its strength and rigidity.

Benefits and Limitations

Benefits:

- Flexibility: Easier to process and shape, particularly useful in packaging.

- Lower Melting Point: Facilitates easier processing and recycling.

Limitations:

- Decreased Strength: Less strength compared to linear polymers, which can limit use in load-bearing applications.

- Poorer Stress Resistance: Susceptible to stress cracking under certain conditions.

Crosslinked Polymers

Structure Overview

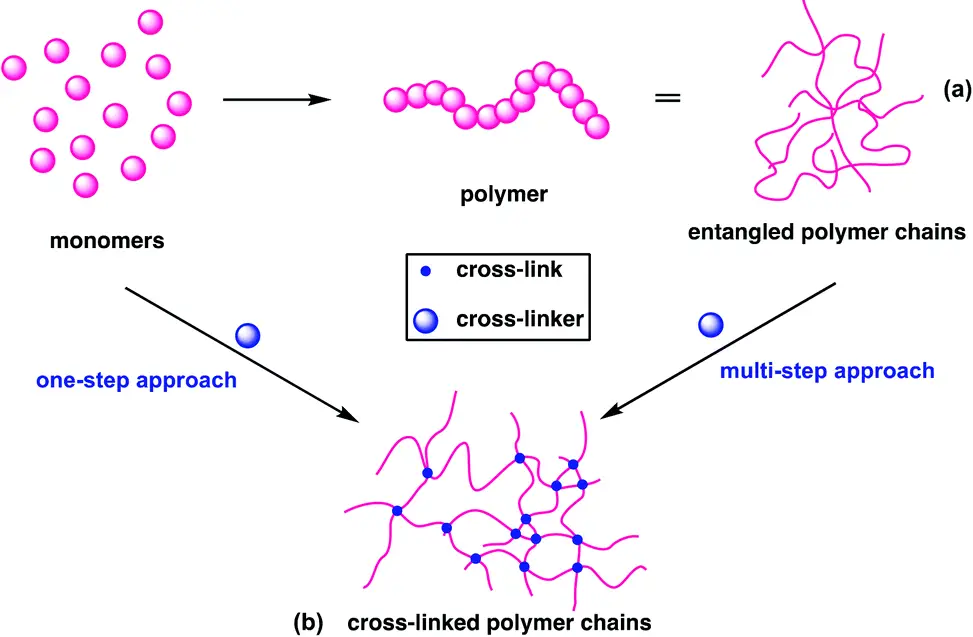

Crosslinked polymers consist of polymer chains interconnected through covalent bonds forming a network. This structure is akin to a net where each junction is chemically bonded, providing a high degree of stability and rigidity.

Examples in Industry

- Epoxy Resins: Used in adhesives and coatings due to their excellent mechanical properties and durability.

- Rubber Tires: The crosslinking in tires provides the necessary toughness and temperature resistance for road use.

Advantages and Drawbacks

Advantages:

- Enhanced Stability: Offers superior dimensional stability and heat resistance.

- Increased Durability: More resistant to chemicals and wear, extending the lifespan of products.

Drawbacks:

- Reduced Flexibility: The rigid network structure can result in less flexibility, which may not be desirable in all applications.

- Complex Processing: Crosslinking can complicate processing, requiring precise control over the conditions to ensure proper bonding.

Key Differences

Structural Variations

The primary distinction between branched and crosslinked polymers lies in their molecular architecture. Branched polymers feature a main chain with additional chains extending outwards, resembling a tree with branches. This structure allows for a degree of movement within the material, impacting its mechanical properties. In contrast, crosslinked polymers are networks of polymers that are chemically bonded to each other at various points, creating a three-dimensional matrix that significantly limits the movement of chains.

Physical Properties

Differences in structure translate directly into variations in physical properties:

- Flexibility and Elasticity: Branched polymers generally offer more flexibility due to their loose branch structures, while crosslinked polymers, with their rigid network, tend to be more brittle unless specifically designed for elasticity.

- Melting Point and Thermal Resistance: Crosslinked polymers often have higher melting points and better thermal stability because of their strong covalent bonds which require more energy to break.

Chemical Behavior

Chemically, the robust nature of crosslinked polymers makes them less reactive and more resistant to solvents and other chemicals compared to branched polymers. This is due to the tightly bound network in crosslinked types, which doesn’t allow molecules of solvents to penetrate easily, thereby maintaining the integrity of the polymer under chemical exposure.

Applications in Industry

Use in Manufacturing

Branched polymers are preferred in manufacturing processes that require malleable and adaptable materials. Their ease of processing makes them ideal for products like:

- Film Packaging: Offers excellent flexibility and is cost-effective for producing wraps and covers.

- Containers and Bottles: Provides the necessary durability and flexibility for everyday consumer products.

Crosslinked polymers are utilized where products need to withstand harsh conditions:

- Automotive Parts: Used in manufacturing parts that must endure extreme temperatures and mechanical stress.

- Electrical Insulations: Ideal for applications requiring robust insulating properties against electrical currents.

Role in Technology

In technology, the unique properties of crosslinked polymers facilitate advancements in:

- Aerospace: Materials that can handle the severe pressure and temperature fluctuations.

- Medical Devices: Utilized in devices requiring sterilization and high chemical resistance.

Branched polymers contribute significantly to:

- Flexible Electronics: Used in the production of flexible screens and wearable technology due to their pliable nature.

Future Perspectives

Innovations and Trends

The future of polymers lies in the ongoing innovation towards materials that are more efficient, sustainable, and capable of performing under extreme conditions. Recent research focuses on developing polymers with self-healing capabilities, enhanced recyclability, and superior performance metrics. Innovations such as nanocomposite polymers and biodegradable polymers are setting trends that promise to revolutionize industries from healthcare to environmental science.

Environmental Impact

The environmental impact of polymers is a critical concern, with emphasis on:

- Recyclability: Branched polymers, due to their simpler structures, are often easier to recycle compared to crosslinked polymers, which can be challenging to break down.

- Biodegradability: Innovations are also geared towards creating both branched and crosslinked polymers that can degrade more efficiently without leaving harmful residues.

Frequently Asked Questions

What Are Branched Polymers?

Branched polymers are characterized by a primary polymer chain with secondary chains branching out from it. This structure can enhance the flexibility and alter the viscosity of the polymer, making it suitable for applications such as packaging materials and non-linear high-density polyethylene.

How Do Crosslinked Polymers Differ?

Crosslinked polymers are polymers where the individual polymer chains are linked together via chemical bonds. This creates a three-dimensional network that provides increased stability and resistance to chemicals and heat, making them ideal for use in automotive parts and heat-resistant appliances.

Why Are Crosslinked Polymers More Stable?

The stability of crosslinked polymers comes from their three-dimensional network structure, which restricts the movement of individual polymer chains. This significantly reduces the material’s ability to flow under heat, thereby enhancing its thermal and mechanical stability.

Where Are Branched Polymers Typically Used?

Branched polymers find extensive use in areas requiring materials with low density and high processability. Common applications include film packaging, bottles, and containers, where their branched structure offers excellent manufacturability and flexibility.

Conclusion

Polymers, particularly branched and crosslinked types, play a pivotal role in various industries due to their tailored properties. The key difference between these polymers lies in their structural makeup, which dictates their functionality and suitability for specific applications. Understanding these differences is crucial for selecting the right material for the right application, ensuring both efficiency and effectiveness.

The exploration of branched and crosslinked polymers opens up a realm of possibilities for future material science innovations. As technology advances, the development of more sophisticated polymer structures could lead to even more specialized applications, further cementing the role of polymers in advancing modern technology and improving daily life.