Polyurethane stands as a cornerstone in the diverse world of polymers, renowned for its adaptability and strength. This versatile material permeates various aspects of everyday life, from simple household items to complex industrial applications. Its unique properties arise from two primary forms: aliphatic and aromatic polyurethane, each with distinct chemical structures and uses.

Aliphatic polyurethane is celebrated for its excellent color stability and resistance to ultraviolet light, making it ideal for outdoor applications where durability is crucial. On the other hand, aromatic polyurethane, though less resistant to UV radiation, offers superior mechanical properties and cost-effectiveness, suited for indoor uses. Understanding these differences is essential for selecting the right type of polyurethane for specific applications, impacting both performance and longevity.

These two types of polyurethane serve distinct purposes based on their chemical makeup. Aliphatic compounds are generally more suitable for surfaces exposed to harsh environmental conditions, while aromatic compounds are often chosen for their strength and economic benefits in protected environments.

Polyurethane Basics

Definition and General Properties

Polyurethane is a versatile type of polymer that consists of organic units joined by carbamate (urethane) links. These polymers are formed through a chemical reaction between a polyol and a diisocyanate or a polymeric isocyanate in the presence of suitable catalysts and additives. The resulting material is highly adaptable, capable of being rigid or flexible, and can take various forms including foams, elastomers, and coatings.

Polyurethane is known for its outstanding flexibility, durability, and resistance to abrasion and solvents. These properties make it an excellent choice for a multitude of applications, ranging from soft furnishings to tough industrial coatings.

Common Applications

- Furniture and Bedding: Used in high-resilience foam seating, mattresses, and upholstery fabrics.

- Automotive Parts: Employed in car interiors for seats, headliners, armrests, and dashboard covers.

- Building Insulation: Spray foam used in walls and roofs to improve energy efficiency.

- Footwear: Used in the soles and insoles of shoes for durability and comfort.

- Coatings and Adhesives: Protective coatings for floors, walls, and other surfaces, and adhesives for various construction materials.

Role in Modern Materials Science

In the realm of materials science, polyurethane plays a pivotal role due to its customizability and broad utility. It supports innovations in various industries by providing materials that are not only effective in their primary function but also enhance sustainability through energy efficiency and resource conservation.

Aliphatic Polyurethane

Chemical Structure

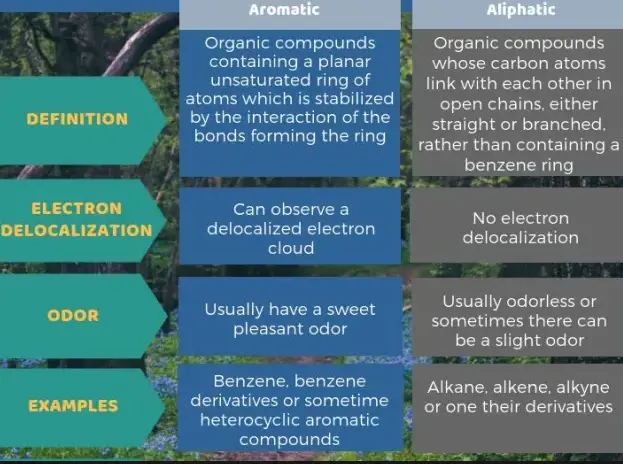

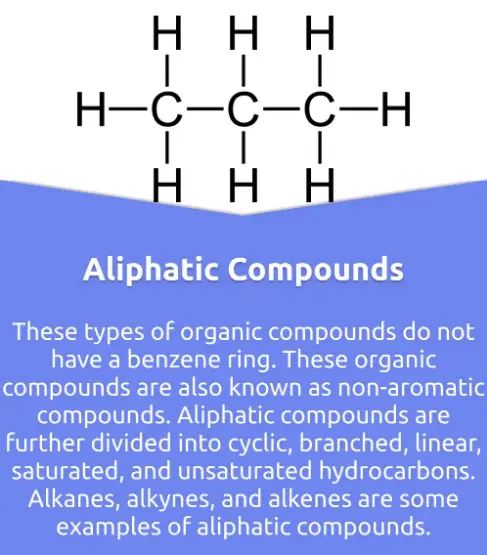

Aliphatic polyurethane is characterized by its aliphatic isocyanate component. This structure does not contain any benzene rings, differing fundamentally from its aromatic counterparts. This molecular difference is crucial in how this type of polyurethane interacts with UV light and other environmental factors.

Key Properties and Benefits

- UV Resistance: Does not yellow or degrade under sunlight, maintaining color and integrity over time.

- Color Stability: Preserves the original color better than other polymers, especially under outdoor conditions.

- Durability: Exhibits excellent mechanical properties, resisting wear and tear in harsh environments.

Typical Uses in Industry

- Automotive Coatings: Used extensively for exterior car parts that are exposed to sunlight and weather.

- Outdoor Furniture: Ideal for garden and patio furniture that requires long-term durability and color retention.

- Protective Coatings: Applied on bridges, buildings, and other structures to protect against weathering and UV damage.

Aromatic Polyurethane

Chemical Structure

Aromatic polyurethane includes aromatic isocyanates, which contain one or more benzene rings. This structure tends to absorb UV light, which can lead to changes in the material’s appearance and properties over time.

Key Properties and Drawbacks

- Cost-Effectiveness: Generally less expensive to produce than aliphatic types.

- Mechanical Strength: Offers robust physical properties suitable for demanding applications.

- UV Sensitivity: The main drawback is its tendency to yellow and degrade when exposed to sunlight, limiting its use in exterior applications.

Typical Uses in Industry

- Foam Products: Widely used in mattresses, seat cushions, and insulation where UV exposure is minimal.

- Interior Finishes: Suitable for indoor applications such as floor and wall coverings, and furniture.

- Industrial Seals and Gaskets: Employed in settings where strong seals are crucial and UV exposure is controlled.

Comparative Analysis

Durability and Longevity

Both aliphatic and aromatic polyurethanes are celebrated for their durability, but they excel in different environments. Aliphatic polyurethane is particularly robust in outdoor settings where it resists weathering and retains its mechanical strength over many years. In contrast, aromatic polyurethane, though strong, is better suited to indoor applications where it is not exposed to UV light which can degrade its properties over time.

Resistance to UV Light

The resistance of aliphatic polyurethane to UV light is one of its most significant advantages. It maintains its clarity and does not yellow, making it ideal for applications like outdoor coatings and automotive finishes. Aromatic polyurethane, however, tends to yellow when exposed to sunlight, which can be a critical drawback for any applications where aesthetic appearance is important.

Color Stability and Aesthetics

Color stability is crucial in applications where the visual appearance of the material impacts the product’s usability or appeal. Aliphatic polyurethane does not discolor easily, which preserves the original aesthetics of the product. Aromatic polyurethane, while strong and effective in many uses, does not offer the same level of color fidelity after prolonged UV exposure.

Cost Considerations

Cost is a significant factor in material selection. Aromatic polyurethane typically costs less than aliphatic variants due to the lower price of aromatic isocyanates. This makes aromatic polyurethane a popular choice for budget-conscious applications within indoor settings where UV stability is less of a concern.

Environmental Impact

Ecological Considerations of Production

The production of polyurethane involves several chemical processes that can be enhanced to reduce environmental impact. Manufacturers are increasingly adopting methods that require less energy and generate fewer byproducts, which reduces the overall ecological footprint of these materials.

Recyclability and Disposal

Polyurethane recyclability is a growing area of interest. Although traditionally challenging to recycle due to its cross-linked structure, developments in chemical recycling techniques are improving the sustainability of polyurethane disposal. These advancements are crucial for minimizing landfill waste and promoting a circular economy.

Comparative Environmental Footprint

When comparing the environmental footprint of aliphatic versus aromatic polyurethanes, it’s essential to consider their entire lifecycle. Aliphatic types, which are more durable and require less frequent replacement, may offer a reduced environmental impact over time compared to aromatic types, which may degrade more quickly and need to be replaced more often.

Industry Applications

Automotive Uses

In the automotive industry, aliphatic polyurethane is used for exterior parts and finishes due to its UV resistance and durability. Aromatic polyurethane finds its use in interior components like foam seating and insulation, where UV stability is not as critical.

Construction and Building Materials

Polyurethane is a key material in construction, particularly in insulation products. Aliphatic types are used in exterior applications for their longevity and resistance to environmental factors, while aromatic types are often used indoors for cost-effective insulation solutions.

Specialty Coatings and Finishes

Specialty coatings that require UV stability and aesthetic preservation, such as those on bridges and outdoor furniture, typically use aliphatic polyurethane. Aromatic polyurethane, however, is suitable for indoor floor and wall coatings where exposure to sunlight is minimal.

Future Trends

Innovations in Polyurethane Technology

The future of polyurethane lies in the development of new formulations that offer greater environmental benefits, enhanced performance, and easier recycling. Innovations include bio-based polyols that reduce reliance on fossil fuels and new catalysts that lower the temperature and energy requirements of production processes.

Emerging Applications

Emerging applications of polyurethane include medical devices and wearable technology, where the material’s flexibility and durability can be leveraged to create new, innovative products that improve user experience and safety.

Sustainability in Polyurethane Production

Sustainability is becoming a cornerstone of polyurethane production. Efforts to minimize the environmental impact of these materials are focused on reducing VOC emissions, using greener raw materials, and enhancing the recyclability of end products.

Frequently Asked Questions

What is Aliphatic Polyurethane?

Aliphatic polyurethane is a type of polymer known for its resistance to sunlight and weather conditions, which prevents yellowing and degradation over time. It’s often used in paints, coatings, and automotive finishes where long-term aesthetic appearance is critical.

What is Aromatic Polyurethane?

Aromatic polyurethane is characterized by its molecular structure which includes aromatic rings, making it less resistant to UV light but more cost-effective. It is commonly used in foams, sealants, and interior finishes where UV exposure is minimal.

How do Aliphatic and Aromatic Polyurethane Differ in Application?

Aliphatic polyurethanes are preferred for applications that require exposure to sunlight and harsh weather, such as exterior paints and coatings. Aromatic polyurethanes are ideal for indoor applications like furniture, bedding, and insulation where UV stability is not a concern.

Why Choose Aliphatic Over Aromatic Polyurethane?

Choosing aliphatic polyurethane over aromatic comes down to the need for UV resistance and color stability. Aliphatic is best for outdoor applications where the material’s appearance and integrity are crucial over long periods.

Can Aromatic Polyurethane Be Used Outdoors?

Aromatic polyurethane can be used outdoors but is not ideal due to its poor UV resistance. It tends to yellow and degrade faster when exposed to sunlight, making it less suitable for exterior applications compared to aliphatic polyurethane.

Conclusion

In summary, aliphatic and aromatic polyurethanes cater to different needs based on their intrinsic properties. Aliphatic polyurethane is indispensable for projects requiring longevity and aesthetic preservation under UV exposure, while aromatic polyurethane offers a cost-effective solution for less demanding interior environments.

Choosing between these materials depends on understanding their distinct benefits and limitations. This knowledge ensures optimal performance and durability of the products made from these versatile polymers, aligning with specific environmental and economic considerations.