Carbon-based materials such as acetylene black and carbon black play crucial roles across various industrial sectors, from manufacturing to electronics. Each type of black carbon material boasts distinct characteristics and production methods, tailored to meet specific needs. This distinction affects everything from conductivity to environmental impact, highlighting the importance of understanding their differences.

Acetylene black and carbon black are both forms of amorphous carbon used extensively in the industry, but they differ significantly in their production processes and physical properties. Acetylene black is produced through the thermal decomposition of acetylene gas, resulting in a carbon black with high purity, conductivity, and surface area. Carbon black, on the other hand, is produced by the incomplete combustion of heavy petroleum products; it is widely used for its reinforcing properties in materials such as rubber.

These materials are pivotal in numerous applications, influencing the performance and durability of products. Acetylene black is preferred in high-power batteries and conductive applications, whereas carbon black is a staple in the automotive tire industry, among others. The selection between the two depends largely on their distinct properties and the specific requirements of the application.

Acetylene Black Basics

Production Process

Acetylene black is created through a specific process known as thermal decomposition. This involves the following steps:

- Acetylene gas, a hydrocarbon, is introduced into a high-temperature furnace.

- The gas decomposes thermally at temperatures around 800°C to 900°C.

- The absence of air during this process prevents combustion, leading to the formation of pure acetylene black instead of burning the acetylene.

This production method is distinctive because it uses acetylene as the sole raw material, which ensures a high degree of purity and structural consistency in the final product. The controlled environment within the furnace is crucial to achieving the desired quality of acetylene black.

Key Characteristics

Acetylene black is known for its:

- High purity: It contains fewer impurities compared to other carbon blacks, which is critical for applications where conductivity and chemical stability are essential.

- High conductivity: Its unique structure allows it to conduct electricity more effectively than most types of carbon black.

- Large surface area: This characteristic enhances its ability to interact with other materials, useful in applications like batteries and capacitors.

- Strong absorption properties: Useful in collecting solar energy and in sensors.

These properties make acetylene black highly valuable in advanced technology applications, particularly in electronics and energy storage.

Carbon Black Overview

How It’s Made

Carbon black is primarily produced by the furnace black process, which includes:

- Feeding heavy petroleum products, such as tar or oil, into a furnace.

- Partially combusting these materials under controlled conditions.

- Collecting the carbon black smoke that results from this combustion.

This method is favored for its efficiency and scalability, making it ideal for producing large volumes of carbon black needed in various industries. Other methods like the lampblack, thermal, and acetylene processes are used but are less common due to specific application requirements or production scale limitations.

Main Properties

Carbon black is notable for its:

- Reinforcing properties: It enhances the strength and durability of materials like rubber.

- Black pigmentation: Widely used as a pigment due to its intense black color.

- UV protection: Offers excellent resistance against ultraviolet light, which helps in prolonging the life of products.

- Electrical conductivity: Although less than acetylene black, it still contributes conductivity in certain applications.

These characteristics make carbon black indispensable in the manufacture of tires, various rubber products, inks, and coatings.

Comparative Analysis

Chemical Structure

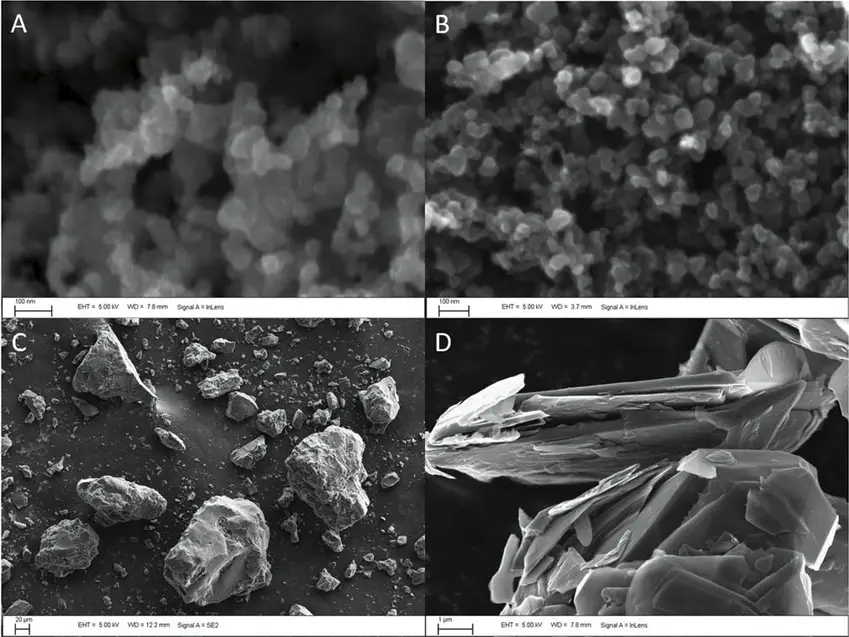

The chemical structure of acetylene black and carbon black differs primarily in the form of their carbon atom links:

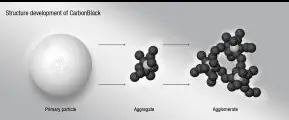

- Acetylene black features a more chaotic, chain-like structure, providing unique electrical properties.

- Carbon black typically exhibits a more clustered, grape-like structure which contributes to its reinforcing capabilities in composites.

These structural differences are key to their respective functional roles in industrial applications.

Physical Differences

Physically, acetylene black and carbon black vary in:

- Particle size: Acetylene black particles are generally larger, which influences their ability to conduct electricity and heat.

- Aggregation: Carbon black particles tend to form more complex aggregates, which affects their dispersibility and mixing properties.

- Surface chemistry: Acetylene black has a cleaner surface, enhancing its interaction with other materials in a mixture.

Applications

Uses of Acetylene Black

Acetylene black is utilized in a variety of high-performance applications due to its superior properties. Key uses include:

- Batteries: It is a critical component in the manufacture of batteries, especially in lead-acid and lithium-ion batteries, where it enhances electrical conductivity and battery life.

- Conductive coatings: Acetylene black is used in the production of conductive paints and coatings, which are applied to electronic devices to prevent electrostatic discharge.

- Electronics: In electronic components, it is used to manufacture capacitors and other energy storage devices due to its high surface area and electrical conductivity.

Uses of Carbon Black

Carbon black has a broad spectrum of applications, primarily due to its reinforcing and pigmentation properties:

- Rubber and tires: It is extensively used in the tire industry, where it provides strength and wear resistance to tires.

- Plastics: Carbon black is added to plastics to enhance their UV protection and to provide pigmentation.

- Inks and coatings: It serves as a pigment in various inks, paints, and coatings, providing deep black coloration and UV protection.

Performance Metrics

Conductivity Comparison

When comparing the conductivity of acetylene black and carbon black:

- Acetylene black exhibits higher electrical conductivity, which makes it preferable for applications requiring efficient current distribution.

- Carbon black has sufficient conductivity for applications like anti-static flooring but is less effective in high-energy environments where acetylene black would be more appropriate.

Durability and Longevity

The durability and longevity of materials incorporating these blacks are crucial:

- In rubber products, carbon black provides significant increases in lifespan and durability, especially in automotive tires.

- In batteries, acetylene black contributes to longer life cycles and enhanced performance over time, essential for high-demand applications like electric vehicles and portable electronics.

Environmental Impact

Emissions in Production

The production processes of acetylene black and carbon black involve different levels of emissions:

- Acetylene black production typically has lower emissions due to its need for purity and the controlled environment in which it is produced.

- Carbon black manufacturing, especially through the furnace method, involves higher levels of CO2 and particulate emissions, which have significant environmental impacts.

Sustainability Factors

Both materials present challenges and opportunities in sustainability:

- Efforts are being made to reduce the environmental footprint of carbon black production by improving process efficiencies and incorporating renewable energy sources.

- For acetylene black, advancements focus on minimizing the use of acetylene and exploring alternative raw materials that could offer similar properties with less environmental impact.

Market Trends

Demand and Supply Dynamics

The demand for both acetylene black and carbon black is influenced by global industrial growth, particularly in the automotive and electronics sectors. Recent trends show:

- Increased demand for acetylene black in high-tech applications.

- Stable demand for carbon black in the tire industry, with innovations aimed at improving product performance.

Future Outlook

Looking ahead, the market for both types of black carbon is poised for evolution:

- Technological advancements in battery technology and electronics will likely increase the demand for acetylene black.

- Sustainability trends will shape the production and application methods for carbon black, potentially leading to cleaner, more efficient processes.

Frequently Asked Questions

What is acetylene black?

Acetylene black is a form of carbon black obtained from the controlled decomposition of acetylene gas, characterized by its exceptionally high purity and conductivity. It is commonly used in battery electrodes and high-performance capacitors due to its ability to enhance electrical and thermal conductivity.

How is carbon black produced?

Carbon black is typically produced by the incomplete combustion of heavy petroleum substances like tar or oil. The process forms a fine black powder, which is then used primarily to reinforce rubber and for pigmentation due to its stability and strength-enhancing properties.

Why choose acetylene black over carbon black?

The choice between acetylene black and carbon black depends on the application’s specific needs. Acetylene black offers superior conductivity and a higher structure, making it ideal for electrical applications, whereas carbon black is favored for its reinforcing qualities in rubber products and its ultraviolet light absorption capabilities.

Are there environmental concerns with producing carbon blacks?

Yes, the production of both types of carbon blacks involves significant environmental considerations. Acetylene black production is less common and can be more controlled, potentially reducing emissions. Carbon black production, however, often involves higher emissions and energy consumption, prompting ongoing research into more sustainable production methods.

Conclusion

The distinct characteristics and applications of acetylene black and carbon black underline the importance of selecting the right material for specific industrial needs. While acetylene black offers enhanced conductivity and purity, making it suitable for electronic applications, carbon black provides critical strength and durability, particularly in the production of tires and rubber goods. Choosing between them necessitates a thorough understanding of their properties and environmental impacts.

In summary, the decision to use acetylene black or carbon black should be informed by their unique attributes and the environmental and economic implications of their production. As industries continue to evolve, the development of more sustainable and efficient production methods will be crucial in mitigating the environmental impacts associated with these essential materials.