Choosing the right material for any application, be it in dentistry, jewelry, or ceramics, requires a deep understanding of the materials available. Two of the most commonly compared materials are zirconia and porcelain, each with its unique set of properties and applications. Their differences span from their chemical composition to their aesthetic appeal, making the choice between them significant for professionals and consumers alike.

Zirconia and porcelain are distinct in their makeup and functionalities. Zirconia, a strong, durable ceramic material, is renowned for its resistance to wear and fracture, making it ideal for high-stress applications like dental implants and crowns. Porcelain, on the other hand, offers unmatched aesthetic qualities with its glass-like translucency and color, preferred in applications requiring a delicate, refined appearance such as veneers and fine dinnerware.

Both materials have carved their niches in various industries due to their specific properties. Zirconia is valued in the medical field for its biocompatibility, while porcelain’s heat resistance makes it a favorite in the culinary and art sectors. Understanding their key differences is crucial for making an informed decision tailored to the specific needs of any application, be it for aesthetic appeal, durability, or a balance of both.

Zirconia Overview

Definition and Properties

Zirconia, or zirconium dioxide (ZrO2), stands out in the world of ceramics for its remarkable strength and durability. This synthetic material has a crystalline structure that endows it with a combination of properties uncommon in traditional ceramics: high fracture toughness, excellent wear resistance, and significant thermal insulation. Its chemical stability under various conditions makes zirconia exceptionally versatile and valuable across numerous applications.

Uses and Applications

The unique properties of zirconia have led to its widespread use in several industries:

- Dentistry: Zirconia is a top choice for dental prosthetics like crowns and bridges. Its strength and color adaptability make it ideal for creating durable, natural-looking dental restorations.

- Jewelry: In the jewelry industry, cubic zirconia, a form of zirconia, is widely recognized as a diamond alternative, prized for its brilliance and clarity.

- Medical Devices: Its biocompatibility makes zirconia suitable for various medical implants, including hip and knee replacements.

- Industrial Uses: Beyond medicine and aesthetics, zirconia’s resistance to wear and high temperatures serves well in manufacturing cutting tools and protective coatings for metals.

Porcelain Overview

Definition and Properties

Porcelain, a type of ceramic made by heating materials, generally including kaolin, in a kiln to high temperatures, combines hardness, translucency, and a white or lightly colored appearance. Historically celebrated for its beauty and rarity, porcelain has evolved from its origins in East Asia to become a staple in both artistic and functional ceramics worldwide. It is renowned for its glass-like surface that can be either glazed or unglazed and its ability to withstand high temperatures while maintaining its aesthetic qualities.

Uses and Applications

Porcelain’s elegance and durability have made it a preferred material for a variety of uses:

- Dentistry: Used for veneers, inlays, onlays, and some types of crowns, porcelain offers a high degree of aesthetic match with natural tooth enamel, thanks to its translucency.

- Tableware and Art: From fine china to decorative sculptures, porcelain is chosen for its beauty and refinement.

- Electrical Insulation: High-grade porcelain serves as an insulator in electrical components due to its excellent thermal resistance.

Key Differences

Physical Properties

Comparing zirconia and porcelain, the differences in physical properties are stark:

- Durability: Zirconia exceeds porcelain in toughness and resistance to fracture. This makes zirconia more suitable for high-load applications such as posterior dental crowns.

- Strength: Zirconia’s strength is notably higher than that of porcelain, which can be more prone to chipping or cracking under pressure.

Biocompatibility

Both materials are biocompatible, making them safe for use in the human body, particularly in dental applications. However, zirconia is often highlighted for its superior strength and minimal wear, contributing to its preference in medical implants over porcelain, which is mainly used for its cosmetic appeal in dentistry.

Aesthetic Comparison

- Color and Translucency: Porcelain wins in terms of aesthetic versatility, offering a closer match to natural tooth enamel due to its translucency and color variability. Zirconia, though versatile, requires more customization to achieve a similar level of aesthetic appeal.

- Applications: The choice between zirconia and porcelain for aesthetic purposes depends on the application’s specific requirements, with porcelain often favored for front teeth restorations and zirconia for areas requiring additional strength.

Cost Implications

The cost of zirconia and porcelain varies depending on the application:

- Dentistry: Zirconia restorations tend to be more expensive than porcelain due to the material’s higher strength and longer lifespan. However, the cost can be offset by the durability and longevity of zirconia-based prosthetics.

- Jewelry and Art: In these applications, the material cost is often less significant compared to the craftsmanship involved, though porcelain items can be more costly due to their intricate designs and labor-intensive production processes.

Maintenance and Longevity

- Zirconia boasts low maintenance and high longevity, particularly in medical and dental applications, where its resistance to wear and staining stands out.

- Porcelain, while durable, requires more careful handling to avoid chipping or cracking. Its lifespan in decorative applications can be extensive with proper care, but in functional uses, especially in dentistry, porcelain may show wear or require replacement sooner than zirconia.

Advantages and Limitations

Zirconia

Advantages

Zirconia stands out for its exceptional strength and durability, positioning it as the material of choice for high-load bearing applications. Key advantages include:

- High Fracture Toughness: Zirconia’s robust structure ensures it can withstand considerable force without cracking, making it ideal for dental implants and crowns.

- Aesthetic Flexibility: While not as translucent as porcelain, advancements in zirconia manufacturing have expanded its color range, allowing for aesthetically pleasing results in dentistry.

- Biocompatibility: Its compatibility with the human body makes zirconia a safe choice for medical implants, reducing the risk of adverse reactions.

- Thermal Insulation: Zirconia’s ability to resist high temperatures without degrading makes it suitable for various industrial applications.

- Minimal Wear: Its resistance to wear ensures longevity, particularly in dental and orthopedic implants.

Limitations

Despite its strengths, zirconia has limitations:

- Cost: The manufacturing process for zirconia is more complex than for traditional ceramics, contributing to higher costs.

- Aesthetic Limitations: While improvements have been made, achieving the same level of translucency and color matching as porcelain can be challenging.

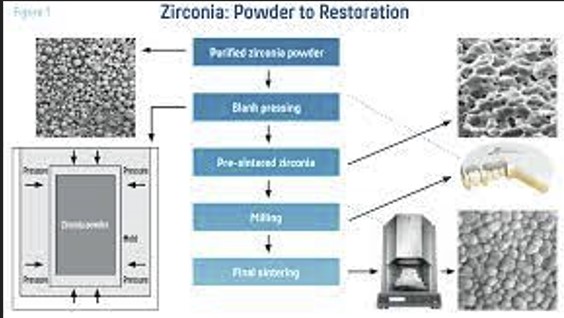

- Technical Requirements: The process of working with zirconia, particularly in dentistry, requires specialized equipment and expertise.

Porcelain

Benefits

Porcelain is celebrated for its aesthetic qualities, offering a blend of beauty and functionality that has been valued for centuries:

- Superior Aesthetics: Its translucency and color matching capabilities make porcelain ideal for applications where appearance is paramount, such as dental veneers and fine china.

- Heat Resistance: Porcelain’s ability to withstand high temperatures without compromising its integrity is beneficial in both artistic and industrial contexts.

- Chemical Stability: It is resistant to most acids and chemicals, ensuring durability in a variety of environments.

Potential Drawbacks

Despite its benefits, porcelain has its drawbacks:

- Fragility: While hard, porcelain can be brittle, making it susceptible to chipping or cracking under pressure or impact.

- Cost of Craftsmanship: The skill required to craft high-quality porcelain items can make them more expensive than alternatives.

- Limited Load-Bearing Capacity: In applications requiring high strength, such as certain dental restorations, porcelain may not be the best choice.

Choosing Between Zirconia and Porcelain

Factors to Consider

When deciding between zirconia and porcelain, several factors come into play, guiding the selection process towards the most suitable material for a given application:

- Application Requirements: Evaluate the physical demands of the application, such as load-bearing capacity and exposure to wear.

- Budget Constraints: Consider the cost implications of each material, including initial expense and long-term maintenance.

- Aesthetic Preferences: Determine the importance of color matching and translucency to the project’s success.

- Durability Needs: Assess the expected lifespan and durability required for the item in its operational environment.

- Technical Capabilities: Take into account the availability of specialized equipment or expertise needed to work with the material.

Expert Recommendations

For professionals navigating the choice between zirconia and porcelain, considering industry standards and professional advice is crucial:

- In Dentistry: For back teeth that require high strength and durability, zirconia is often recommended. Porcelain, due to its superior aesthetic qualities, may be preferred for front teeth where appearance is more critical.

- In Jewelry: Cubic zirconia is a popular choice for those seeking diamond-like clarity at a lower cost, while porcelain offers a unique aesthetic for artisanal pieces.

- In Medical Implants: Zirconia is favored for its biocompatibility and strength, making it a reliable option for various types of implants.

- In Art and Ceramics: Porcelain remains the material of choice for projects requiring fine detailing and a high-quality finish.

Frequently Asked Questions

What is zirconia primarily used for?

Zirconia is widely used in the medical field, particularly in dentistry, for implants, crowns, and bridges due to its exceptional strength and durability. Its biocompatibility and wear resistance also make it suitable for orthopedic applications, such as joint replacements.

How does porcelain compare to zirconia in terms of aesthetics?

Porcelain offers superior aesthetics compared to zirconia, with its glass-like translucency and ability to closely mimic the natural appearance of teeth and delicate ceramics. This makes it a preferred choice in applications where visual appeal is paramount, such as dental veneers and fine china.

Can zirconia be considered more durable than porcelain?

Yes, zirconia is generally considered more durable than porcelain. It has a higher fracture toughness and wear resistance, making it more suitable for applications that require long-term durability, such as dental restorations and some types of industrial ceramics.

Is porcelain or zirconia better for dental applications?

The choice between porcelain and zirconia for dental applications depends on the specific needs of the patient. Zirconia is often chosen for its strength and durability, especially for back teeth crowns and implants. Porcelain, however, is preferred for its aesthetic qualities, making it ideal for front teeth veneers and crowns.

Conclusion

In the comparison between zirconia and porcelain, each material emerges with its strengths, tailored to meet specific needs across various industries. The choice between them should be guided by a clear understanding of their properties, from durability and biocompatibility to aesthetics and cost.

Making an informed decision requires weighing these factors against the application’s specific demands, whether it be for a piece that combines strength and beauty or for one that stands up to daily wear and tear. As technology advances, the capabilities of both materials may evolve, but their distinct characteristics will continue to serve as a guide for choosing the right material for the right application.