Non-Newtonian fluids exhibit behaviors that defy the classical laws of viscosity observed in Newtonian fluids like water or oil, which maintain a constant viscosity regardless of the forces applied to them. This category encompasses a fascinating range of substances, from everyday items like ketchup to industrial materials used in the creation of novel products. Their unique properties open a world of possibilities in various applications, driving innovation and efficiency across multiple industries.

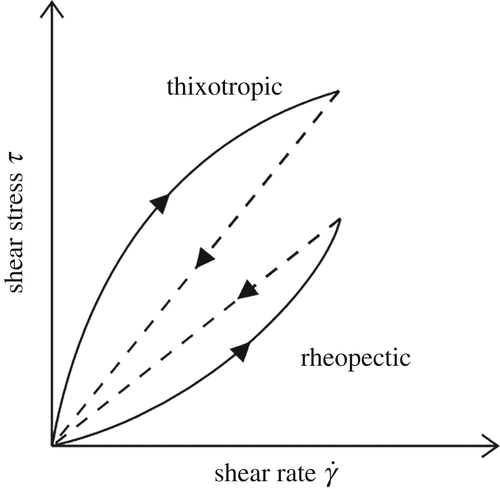

The primary difference between thixotropic and rheopectic fluids lies in how their viscosity changes over time when subjected to a constant shear rate. Thixotropic fluids become less viscous, or thinner, over time under constant stress, whereas rheopectic fluids do the opposite, becoming more viscous, or thicker, under the same conditions. This distinct behavior underpins the unique applications and challenges associated with each type of fluid.

Thixotropic fluids, such as certain gels and creams, find applications in fields ranging from pharmaceuticals to food production, offering the ability to flow easily when shaken, stirred, or otherwise agitated, then return to a more solid state. Rheopectic fluids, though less common, play crucial roles in areas like robotics and wearable technology, where their increasing viscosity under stress can provide shock absorption or increased support dynamically. Understanding these materials’ underlying mechanisms and behaviors illuminates their potential impacts on technology, industry, and our daily lives.

Basic Concepts

Non-Newtonian Fluids

Definition and significance

Non-Newtonian fluids are substances that do not follow Newton’s law of viscosity consistently. In simpler terms, their viscosity—or resistance to flow—changes when an external force is applied. This characteristic sets them apart from Newtonian fluids like water or oil, whose viscosity remains constant regardless of the applied force. Non-Newtonian fluids are crucial in everyday products and industrial applications, from ketchup that flows more easily out of a bottle when shaken to medical gels that must adapt to different pressures during application.

Thixotropic Fluids

Definition

Thixotropic fluids are a type of non-Newtonian fluid that becomes less viscous over time under a constant shear rate. Once the stress is removed, they gradually return to their original viscosity. This means thixotropic materials can be solid-like at rest but become fluid-like when agitated or stressed. Examples include certain paints and clays, which are easy to spread when stirred or applied but retain their shape when left undisturbed.

Rheopectic Fluids

Definition

In contrast, rheopectic fluids are much rarer and exhibit the opposite behavior to thixotropic fluids. They become more viscous, or thicker, under the application of stress. This increase in viscosity occurs over time when a constant stress is applied. Rheopectic substances are less commonly encountered in daily life but have fascinating applications in areas like protective gear and novel materials, where their unique properties can be leveraged for dynamic response to environmental forces.

Key Differences

Time-dependent Behavior

The most striking difference between thixotropic and rheopectic fluids is their time-dependent behavior in response to stress. Thixotropic substances thin out over time under stress, becoming easier to manipulate before eventually returning to their original state. Rheopectic fluids, conversely, thicken over time when stressed, offering a unique mechanism for absorbing and dissipating energy.

Applications

Industrial and everyday examples

Thixotropic and rheopectic fluids find roles in numerous applications, underpinning the functionality of many products and industrial processes. Thixotropic materials, for example, are vital in the manufacture of inks, coatings, and adhesives, where controlled flow and stability are essential. Rheopectic materials, although less common, show promise in innovative technologies like shock absorbers in protective gear, where their ability to become more viscous under impact can provide enhanced protection.

Impact on Industries

The unique properties of thixotropic and rheopectic fluids have a profound impact on industries, driving innovation and improving efficiency. In the pharmaceutical industry, thixotropic gels enable precise drug delivery by flowing easily under pressure but staying in place once applied. In construction, thixotropic additives improve the workability of concrete and mortar. Rheopectic fluids are exploring frontiers in wearable technology and robotics, where their dynamic viscosity can offer adaptive support or resistance based on the user’s needs.

Mechanisms Behind the Behavior

Thixotropy Mechanics

The molecular structure and interactions within thixotropic fluids are key to their behavior. These substances typically contain particles or polymers that form a weak, structured network in their rest state. When subjected to shear stress, this network breaks down, reducing the fluid’s viscosity. The gradual rebuilding of the structure once the stress is removed leads to the recovery of the original viscosity. This behavior is instrumental in applications requiring a temporary reduction in viscosity, such as in the spreading of paints or the extrusion of creams.

Rheopexy Mechanics

Rheopectic fluids operate on a similar principle but in reverse. Under stress, the particles or polymers in these fluids form stronger interactions over time, leading to an increase in viscosity. The strengthening of these bonds under continuous shear stress makes rheopectic substances thicker and more resistant. This mechanism is exploited in areas where increased viscosity upon stress can provide benefits, such as in energy-absorbing layers in protective equipment or in materials that stiffen dynamically for structural support.

Practical Implications

Material Science

The importance of thixotropy and rheopexy in material formulation

In the realm of material science, the concepts of thixotropy and rheopexy play pivotal roles in crafting substances with desired behaviors and properties. These fluid behaviors enable scientists and engineers to design materials that can perform under specific conditions, enhancing both usability and functionality.

For instance, thixotropic additives in paints ensure ease of application with a brush or roller while preventing dripping or sagging once applied. Similarly, rheopectic fluids are being explored for smart materials that strengthen under stress, ideal for protective clothing or dynamically adaptive structures. This tailoring of material properties is essential in sectors ranging from biomedical engineering to aerospace, where precision and adaptability can significantly impact performance and safety.

Engineering and Design

How engineers use knowledge of these fluids in product design

Engineers leverage the unique properties of thixotropic and rheopectic fluids to solve complex design challenges, creating products that are both innovative and practical. In automotive engineering, thixotropic lubricants facilitate smoother operation under normal conditions but thicken to protect components under high stress.

Designers of consumer electronics utilize rheopectic compounds in vibration dampening systems, ensuring that devices can absorb shocks from drops or impacts more effectively. This knowledge enables the development of products that are not only more durable and efficient but also safer and more enjoyable to use.

Environmental Impact

Considerations in sustainability and environmental friendliness

The environmental implications of utilizing thixotropic and rheopectic materials are increasingly coming under scrutiny. Researchers and manufacturers are focused on developing eco-friendly formulations that do not compromise performance.

This includes sourcing biodegradable thixotropic agents for cosmetics and personal care products, reducing the environmental impact of products that are washed away or disposed of after use. Additionally, the advancement in renewable energy technologies benefits from rheopectic fluids in hydraulic systems that can adapt to fluctuating pressures and loads, optimizing efficiency while minimizing waste.

Challenges and Solutions

Measurement and Control

Techniques for accurately measuring and controlling fluid properties

Measuring and controlling the properties of thixotropic and rheopectic fluids present significant challenges due to their time-dependent viscosity changes. However, advanced rheological testing methods have been developed to accurately characterize these behaviors. These include:

- Rotational rheometry, which applies controlled stress or strain to measure viscosity changes over time.

- Oscillatory rheometry, useful for understanding the structural recovery of thixotropic materials after deformation.

These techniques enable scientists to precisely tailor fluid properties to specific applications, ensuring consistent performance and quality.

Overcoming Limitations

Strategies to enhance the performance of thixotropic and rheopectic materials

To overcome the inherent limitations of thixotropic and rheopectic materials, researchers are focusing on innovative formulations and hybrid materials. For example, nano-engineering techniques are being used to create composite materials that combine the desirable aspects of both behaviors, offering adjustable viscosity in response to different stimuli. Furthermore, advancements in polymer science are leading to the development of synthetic molecules that exhibit enhanced thixotropic or rheopectic properties, opening up new possibilities for application in fields as diverse as medicine and construction.

Future Directions

Research Frontiers

Emerging studies on non-Newtonian fluids

The frontier of research in non-Newtonian fluids is rapidly expanding, with new discoveries shedding light on the molecular mechanisms behind thixotropy and rheopexy. Cutting-edge studies are exploring the potential of bio-inspired materials, mimicking the adaptive fluid behaviors found in nature, such as the reversible gel-sol transitions in certain plant exudates or animal secretions. These studies not only deepen our understanding of fluid dynamics but also inspire novel applications in smart materials and bioengineering.

Technological Advancements

Innovations enabling new applications of thixotropic and rheopectic fluids

Technological advancements continue to unlock new applications for thixotropic and rheopectic fluids. 3D printing technology, for example, benefits greatly from thixotropic inks, which must flow through the printer nozzle but quickly solidify to maintain shape once deposited. On the frontier of wearable technology, researchers are developing rheopectic gel-infused fabrics that harden upon impact, offering potential for creating more effective and comfortable protective gear. These innovations demonstrate the vast potential of thixotropic and rheopectic materials to revolutionize industries and improve daily life, highlighting the importance of ongoing research and development in this fascinating field.

Frequently Asked Questions

What are Non-Newtonian fluids?

Non-Newtonian fluids are substances that do not follow Newton’s law of viscosity; meaning their viscosity can change when under force, rather than remaining constant. This unique characteristic allows them to behave differently under various conditions, making them invaluable in numerous applications across medical, culinary, and industrial fields.

How do thixotropic fluids work?

Thixotropic fluids decrease in viscosity when subjected to stress or agitation and gradually return to their original state when the stress is removed. This behavior is due to the breakdown of internal structures within the fluid, making them ideal for applications requiring temporary liquidity, such as in paints and medical ointments.

What makes rheopectic fluids unique?

Rheopectic fluids are unique because they become thicker, or more viscous, under stress. This rare property is seen in very few materials, like some synthetic lubricants or gels, which can absorb energy and provide cushioning or resistance, beneficial in protective gear or dynamic load-bearing applications.

Why are thixotropic and rheopectic fluids important in industry?

Thixotropic and rheopectic fluids are vital in various industries due to their unique behaviors under stress, allowing for innovative solutions to complex problems. Thixotropic fluids are key in manufacturing and processing industries where controlled flow and stability are required, while rheopectic fluids offer potential in developing responsive systems and materials for new technology and protective equipment.

Conclusion

The exploration of thixotropic and rheopectic fluids opens a gateway to understanding the vast potential of non-Newtonian fluids in transforming technology and industry. These materials challenge traditional notions of viscosity and fluid behavior, offering unique properties that can be harnessed for innovative applications, from medical therapies to advanced manufacturing processes.

Their study not only advances our knowledge of material science but also inspires new solutions to longstanding challenges. As research continues to unveil the complexities of these fluids, their integration into new and existing technologies promises to enhance efficiency, safety, and performance across a broad spectrum of applications, underscoring the importance of continued exploration in this dynamic field.