Viscosity is a fundamental property of fluids that describes their resistance to flow. Different fluids respond differently under stress, and their viscosity can change based on how they’re handled or processed. This variability leads to classifications such as thixotropic and pseudoplastic, each describing a unique behavior under stress which is crucial in numerous industrial and everyday applications.

Thixotropic fluids decrease in viscosity when subjected to stress over time, then slowly return to their original state once the stress is removed. In contrast, pseudoplastic fluids also become less viscous under stress but do so immediately and reversibly without the time dependency. These behaviors have significant implications across various fields including manufacturing, pharmaceuticals, and food production.

Understanding these fluid behaviors enhances efficiency and efficacy in applications where precise material manipulation is required. From the foods we eat to the medicines we rely on, the dynamic nature of these fluids impacts their processing and use, influencing everything from texture to efficacy.

Fluid Behavior Basics

Definition of Fluid Viscosity

Viscosity refers to a fluid’s resistance to flow. In simpler terms, it’s a measure of how thick or sticky a fluid is. When you pour syrup, it flows slowly because of its high viscosity, whereas water, with low viscosity, flows quickly. This property is not just a characteristic of fluids like liquids and gases but also influences how these substances are used in various applications, from industrial lubricants to everyday products like shampoos.

Types of Fluid Viscosities

There are several types of viscosity behaviors in fluids, which can broadly be classified based on how they react to being moved or stressed:

- Newtonian Fluids: Their viscosity does not change regardless of the stress applied. Water and air are classic examples.

- Non-Newtonian Fluids: Their viscosity changes when stress is applied. This category is further divided into fluids that thicken under stress (dilatant) and those that thin under stress, including thixotropic and pseudoplastic fluids.

Thixotropic Fluids

Definition and Characteristics

Thixotropic fluids are those that decrease in viscosity over time when under stress, such as stirring or shaking, and then gradually return to their original state when the stress is removed. This behavior is essential in applications where controlled flow is necessary.

Common Examples

Common examples of thixotropic materials include:

- Paints: Easier to apply when stirred and thicken when left to rest.

- Ketchup: Flows more freely from the bottle when shaken.

- Cosmetic gels: Spread smoothly on the skin when applied and then set.

Pseudoplastic Fluids

Definition and Characteristics

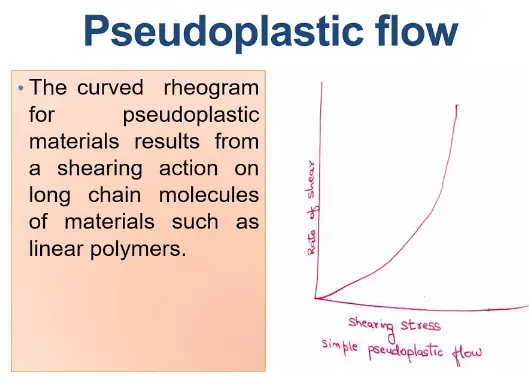

Pseudoplastic fluids exhibit a decrease in viscosity immediately upon application of stress but revert instantly when the stress is removed. Unlike thixotropic fluids, their change in viscosity is not time-dependent but is immediate and reversible.

Common Examples

Examples of pseudoplastic substances are prevalent in various industries:

- Yogurt: Maintains a firm shape in a container but flows easily when stirred or spooned.

- Blood: Flows easily through veins and arteries but can thicken when at rest.

Key Differences

Response to Shear Stress

The primary difference between thixotropic and pseudoplastic fluids lies in their response to shear stress:

- Thixotropic Fluids: Require time to change viscosity when stress is applied and to revert back.

- Pseudoplastic Fluids: Respond immediately to applied stress without delay and revert instantly when stress is removed.

Time Dependence

Another critical aspect is time dependence:

- Thixotropic fluids exhibit a time-dependent viscosity change, meaning their properties are impacted by the duration of the applied stress.

- Pseudoplastic fluids do not show time-dependent behavior, making them ideal for processes requiring immediate fluidity adjustments.

Practical Applications

Understanding these properties is crucial for optimizing various processes:

- Thixotropic fluids are favored in applications like painting or adhesive application, where a gradual return to initial viscosity after application ensures better handling and setting.

- Pseudoplastic fluids are essential in food processing and medical applications where immediate fluidity changes are necessary for mixing, pumping, or injecting.

Industrial Applications

Thixotropic Fluids Uses

Thixotropic fluids are essential in a variety of sectors due to their unique viscosity characteristics that facilitate easier application and stable performance. Key uses include:

- Paints and Coatings: Thixotropy in paints allows for easy application with a brush or roller. As the paint is applied and sheared, it becomes fluid, but it thickens upon resting, preventing drips and improving finish quality.

- Adhesives: Many adhesives are thixotropic to prevent sagging or running during application. This property ensures that adhesives stay in place on vertical surfaces until they cure.

- Personal Care Products: Gels and creams often utilize thixotropic properties to spread smoothly during application and then set without dripping.

Pseudoplastic Fluids Uses

Pseudoplastic fluids find their importance in industries where immediate viscosity adjustment is crucial for processing efficiency. Their applications include:

- Food Production: Many food products like sauces and dressings benefit from pseudoplasticity for easy bottling and mixing while maintaining a thick consistency in the package.

- Pharmaceuticals: Drug delivery systems often require pseudoplastic carriers to ensure easy injection or dispensing followed by rapid thickening to stay at the target site.

- Cosmetics: Lotions and shampoos exhibit pseudoplastic behavior to pour easily and then coat the skin or hair evenly without running off.

Technical Challenges

Measurement Techniques

Accurately measuring the viscosity of thixotropic and pseudoplastic fluids poses significant challenges due to their changing properties under stress. Techniques often employed include:

- Rotational Viscometers: These devices measure the torque required to rotate a spindle at constant speed in the fluid, providing insights into viscosity changes with varying shear rates.

- Rheometers: More sophisticated than viscometers, rheometers can apply controlled stress or strain while measuring the resulting flow properties, crucial for characterizing non-Newtonian fluids.

Handling and Processing

Handling and processing non-Newtonian fluids require specific considerations to maintain product consistency and quality:

- Temperature Control: Since viscosity can be sensitive to temperature, maintaining a controlled environment during processing is vital.

- Shear Management: Excessive shear can permanently alter the properties of thixotropic and pseudoplastic fluids. Equipment and process design must minimize unwanted shear while still achieving necessary fluid movement.

Advances in Research

Recent Findings

Recent advancements in the study of non-Newtonian fluids have led to better understanding and innovations:

- Nano-Additives: The incorporation of nano-sized additives into fluid formulations has been shown to enhance thixotropic and pseudoplastic behaviors, allowing for more precise control over viscosity and flow properties.

- Environmental Sensitivity: New research indicates that some thixotropic and pseudoplastic fluids can be designed to respond to environmental triggers such as pH changes or temperature shifts, expanding their applications in smart materials and responsive technologies.

Future Directions

Looking forward, the field of non-Newtonian fluid dynamics is poised for significant growth with implications across multiple industries:

- Biomedical Applications: Thixotropic and pseudoplastic materials are increasingly important in biomedical engineering, such as in drug delivery systems where controlled release and site-specific targeting are paramount.

- Sustainable Materials: As industries seek more environmentally friendly solutions, advancements in naturally derived thixotropic and pseudoplastic materials are anticipated.

- Advanced Manufacturing Techniques: 3D printing and other novel manufacturing technologies are exploring the use of thixotropic and pseudoplastic fluids to create complex structures that benefit from variable viscosity.

Frequently Asked Questions

What are Thixotropic Fluids?

Thixotropic fluids are substances that become less viscous over time when shaken, stirred, or otherwise stressed. This reversible and time-dependent decrease in viscosity is essential in applications like paints and varnishes, where ease of application and stable storage are both required.

How do Pseudoplastic Fluids Behave?

Pseudoplastic fluids decrease in viscosity under stress but unlike thixotropic fluids, this change occurs immediately and reversibly. This characteristic is crucial in industries like food processing where shear-thinning properties can affect mixing and bottling processes.

Why is Viscosity Important?

Viscosity is critical because it affects how fluids flow and behave under different conditions. High viscosity fluids flow slowly, like honey, whereas low viscosity fluids like water flow quickly. The control of viscosity in manufacturing processes can greatly affect product quality and production efficiency.

What Makes Thixotropic and Pseudoplastic Fluids Different?

The key difference lies in how they respond to time under stress. Thixotropic fluids need time to change viscosity and revert slowly, while pseudoplastic fluids respond and recover immediately. Each type plays a crucial role in their respective applications based on these behaviors.

Conclusion

The distinction between thixotropic and pseudoplastic fluids is more than just academic—it’s a critical factor in the design and optimization of countless products and processes. By understanding these properties, engineers and scientists can tailor materials to behave exactly as needed under specific conditions.

In conclusion, recognizing and exploiting the unique characteristics of these fluid types not only enhances product design but also fosters innovation in material science. As we continue to explore the boundaries of fluid dynamics, the role of viscosity in industrial and consumer products will undoubtedly expand, leading to more sophisticated and tailored material solutions.