Sealants and adhesives play a pivotal role in a myriad of applications, from the assembly of complex machinery to simple household repairs. Among the vast array of materials available, RTV (Room Temperature Vulcanizing) and silicone stand out for their unique properties and versatility. These substances are essential in creating durable, flexible, and weather-resistant seals, yet their distinctions aren’t always clear to the end user.

RTV is a type of silicone that cures at room temperature, transforming from a viscous liquid to a solid rubbery texture. It’s distinguished by its ease of use and ability to form strong, flexible seals that withstand high temperatures and chemical exposures. Conversely, silicone encompasses a broader category of polymers that include RTV as a subset, offering various formulations for diverse applications, each with specific curing methods and physical properties.

The crux of choosing between RTV and silicone lies in understanding their chemical compositions, curing processes, and resultant physical properties. While RTV silicone is prized for its straightforward application and effective sealing capabilities, other silicone forms offer tailored characteristics for specialized uses. The decision hinges on the specific requirements of the application, including the expected environmental conditions and physical stresses the material will face.

RTV: An Overview

What is RTV?

RTV stands for Room Temperature Vulcanizing silicone. This unique material cures or sets into a durable, rubbery state when exposed to the air at room temperature. The term vulcanizing refers to the chemical process that transforms the silicone from a liquid or semi-liquid form into a solid. The key components of RTV silicone include a base of silicone polymers, a vulcanizing agent, and various fillers that improve its properties.

RTV silicone is distinct for its ability to cure without the need for added heat, making it highly versatile and easy to use across various applications. The curing process is initiated when the RTV compound is exposed to moisture in the air, leading to a cross-linking reaction among the silicone polymers. This reaction creates a strong, flexible, and water-resistant material.

Types of RTV

RTV silicones can be broadly categorized into one-part and two-part systems, each with its unique characteristics and uses.

One-Part RTV Silicone

- Cures at room temperature upon exposure to air moisture.

- Easy to use, requiring no mixing or special preparations.

- Ideal for sealing, bonding, and protective coatings.

- Commonly used in construction, automotive, and electronic applications.

Two-Part RTV Silicone

- Consists of a base and a catalyst that must be mixed before use.

- Offers faster cure times and greater flexibility in working time before curing.

- Suitable for more demanding applications where higher performance is needed.

- Used in molding, casting, and high-strength bonding tasks.

These types allow for flexibility in application, depending on the specific requirements of the project, such as cure time, environmental resistance, and mechanical properties.

Common Uses

RTV silicone serves a wide range of industries due to its outstanding flexibility, temperature resistance, and chemical stability. Some of the common applications include:

- Sealing and gasketing in automotive and aerospace components, providing leak-proof seals.

- Electrical insulation, where its dielectric properties protect sensitive components.

- Mold making for artistic and industrial parts, thanks to its ability to reproduce fine details and resist chemicals.

- Adhesion to various materials, including glass, metal, and plastic, in construction and repair tasks.

The diversity of RTV silicone’s applications underscores its utility as a sealant and adhesive with unparalleled versatility.

Silicone Basics

What is Silicone?

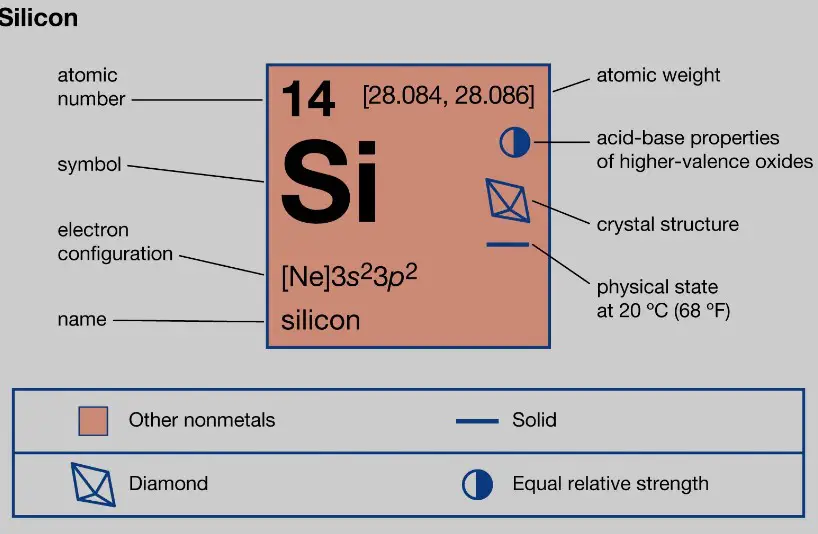

Silicone is a broad term that encompasses a wide range of synthetic polymers known for their rubbery texture, heat resistance, and water-repellent properties. Unlike conventional organic rubbers, silicones possess a backbone of silicon and oxygen atoms, rather than carbon and hydrogen. This unique chemical structure imparts silicone materials with their characteristic durability and stability across extreme temperatures and environmental conditions.

Silicones are not limited to RTV varieties but extend to several other forms, each tailored for specific applications and performance requirements. These materials are celebrated for their versatility, finding roles in everything from medical devices to kitchenware.

Types of Silicone

The world of silicone materials is vast, with each type designed for particular uses based on its physical and chemical properties.

Liquid Silicone Rubber (LSR)

- Highly fluid, allowing for easy molding and casting.

- Cures into a flexible, durable rubber, ideal for medical devices, seals, and kitchen utensils.

High-Temperature Vulcanizing (HTV) Silicones

- Requires heat to cure, resulting in a very heat-resistant product.

- Used in applications that demand extreme temperature performance, such as automotive engine parts and industrial machinery.

Other Forms

- Silicone resins, which form hard, durable coatings and insulators.

- Silicone gels, known for their soft, flexible, and tacky texture, often used in cosmetic and medical applications for cushioning and protection.

Each of these types is engineered to meet specific challenges, whether it’s the need for flexibility, durability, or resistance to harsh conditions.

Common Uses

Silicone’s remarkable properties make it invaluable across a wide spectrum of applications. From industrial uses to household products, silicone’s presence is ubiquitous.

- Medical devices and implants, where its biocompatibility and stability are critical.

- Automotive parts, including hoses, gaskets, and seals, due to its temperature and chemical resistance.

- Cookware and baking molds, favored for their non-stick properties and safety at high temperatures.

- Electronics, where silicone provides insulation, protection, and heat resistance for components.

Key Differences

Chemical Composition

RTV silicone and other silicone materials have distinct chemical structures that determine their properties and applications. RTV silicone is primarily made of polydimethylsiloxane (PDMS), with curing agents that react at room temperature. This composition allows it to vulcanize without additional heat, making it versatile for various settings.

On the other hand, silicones can vary widely in their chemical makeup, including different polymers and crosslinking methods. For example, liquid silicone rubber (LSR) contains a platinum-catalyzed curing system, while high-temperature vulcanizing (HTV) silicones use organic peroxides as curing agents. These differences in chemical structure influence the material’s strength, elasticity, and resistance to environmental factors.

Curing Process

The curing process is a key differentiator between RTV silicone and other types of silicone. RTV silicone cures at room temperature once exposed to atmospheric moisture, which initiates a cross-linking reaction that turns the liquid into a solid. This process is convenient for applications where heating is impractical or undesirable.

In contrast, other silicones, such as HTV and LSR, require heat to initiate the curing process. This need for thermal energy can limit their use in heat-sensitive environments but allows for faster curing times and greater control over the process in industrial settings.

Physical Properties

RTV silicone is renowned for its flexibility, temperature resistance, and durability. It maintains its elasticity over a wide temperature range, from about -60°C to 200°C, making it ideal for applications experiencing thermal expansion or contraction.

Other silicone materials may offer higher temperature resistance or enhanced mechanical properties like tensile strength or tear resistance. For instance, HTV silicones can withstand temperatures up to 300°C, and LSR offers exceptional flexibility and strength, making them suitable for demanding industrial applications.

Application Methods

The application method for RTV silicone typically involves direct application from a tube or cartridge, making it accessible for DIY projects and professional use alike. It can be applied to create seals or bonds without the need for special equipment.

Other silicone forms might require more complex application processes, including molding and casting for LSR or the use of compression molding for HTV silicones. These methods are more commonly found in industrial manufacturing, where precision and volume are critical.

Selection Criteria

When to Use RTV

RTV silicone is the preferred choice in situations where a durable, flexible seal is required, and the application area is exposed to varying temperatures or moisture. It’s ideal for sealing windows, bathrooms, and outdoor fixtures. RTV is also beneficial for electrical insulation and automotive gaskets due to its excellent adhesion and resistance properties.

When to Use Other Silicones

Other forms of silicone are more appropriate when specific physical properties are needed, such as higher temperature resistance, greater mechanical strength, or flexibility. LSR is chosen for medical devices and baby products due to its purity and biocompatibility. HTV silicones are used in aerospace and automotive parts for their superior heat resistance.

Advantages and Disadvantages

RTV Pros and Cons

Advantages of RTV silicone include its ease of use, excellent sealing properties, and versatility across a range of temperatures and environments. It’s also relatively inexpensive and available in various formulations to suit different needs.

However, RTV silicone may not be suitable for high-stress applications where mechanical properties like high tensile strength or tear resistance are crucial. Its cure time can also be a limitation in rapid production environments.

Silicone Pros and Cons

Silicone materials, in general, offer a broad range of physical properties that can be tailored to specific applications, from high-strength industrial parts to flexible medical devices. They are resistant to chemicals, temperature extremes, and UV light, making them durable in harsh conditions.

The downsides include the need for special processing equipment and potentially higher costs for certain types. Additionally, some silicone types may not be compatible with all substrates, requiring surface treatment or special adhesives.

FAQs

What is RTV Silicone?

RTV silicone is a type of silicone that cures at room temperature to form a flexible, durable seal. It’s widely used for sealing, bonding, and insulating in automotive, aerospace, and electronics applications. Its ability to withstand extreme temperatures, pressures, and chemical exposures makes it an ideal choice for challenging environments.

How Does Silicone Differ from RTV?

Silicone refers to a broad group of synthetic polymers, of which RTV is just one type. The main difference lies in their curing processes and applications. While RTV cures at room temperature without needing any added heat, other silicones might require high temperatures or specific conditions to cure. Each type of silicone serves distinct purposes across various industries due to their unique properties.

When Should I Use RTV Over Other Silicones?

Choose RTV silicone when you need a reliable sealant that cures at room temperature without requiring additional heat or equipment. It’s perfect for applications needing quick, efficient seals that can withstand environmental stresses, including temperature fluctuations and moisture. RTV is also preferred for its ease of use in both professional and DIY contexts.

Can RTV Silicone Be Used Outdoors?

Yes, RTV silicone is excellent for outdoor applications due to its UV resistance and ability to withstand extreme weather conditions. It maintains its flexibility and sealing properties in both high and low temperatures, making it suitable for outdoor fixtures, automotive applications, and construction sealing tasks.

Conclusion

Selecting between RTV and silicone involves a nuanced understanding of their distinct properties and the specific demands of the intended application. RTV silicone offers unparalleled ease of use and robust performance under a wide range of conditions, making it a go-to choice for many sealing and bonding tasks. However, the broader family of silicone materials presents a spectrum of options designed to meet specialized requirements, from high-temperature operations to food-grade applications.

Ultimately, the decision rests on assessing the application’s needs against the material’s properties. By considering factors such as temperature resistance, chemical exposure, and physical stresses, one can choose the most appropriate material. Whether it’s the versatile RTV for general-purpose sealing or a specialized silicone for unique applications, understanding the differences ensures the longevity and reliability of the seal or bond formed.