Sonication technology plays a pivotal role in modern scientific research and industrial applications, utilizing sound waves to agitate particles in a sample. This technique is widely applied in fields ranging from biochemistry to engineering, proving essential for processes that require precision and efficiency. Two primary types of sonicators, probe and bath sonicators, facilitate these processes, each offering distinct advantages and operational modes.

The main difference between probe sonicators and bath sonicators lies in their design and application. A probe sonicator works by directly immersing a probe into the sample to deliver intense sonic energy, making it suitable for disrupting cell structures or mixing solutions on a small scale. In contrast, a bath sonicator cleans or processes multiple samples simultaneously through indirect sonication in a water bath, ideal for more delicate tasks requiring uniform treatment.

Understanding the operational distinctions and applications of these devices is crucial for selecting the appropriate sonicator. Each type is tailored to specific tasks, influencing their effectiveness and integration into various workflows. This knowledge not only enhances operational efficiency but also optimizes outcome quality, key considerations for any professional engaged in sonication-dependent activities.

Sonication Basics

What is Sonication?

Sonication refers to the process of applying sound energy, specifically high-frequency ultrasonic waves, to agitate particles in a sample. This method is pivotal in numerous scientific and industrial applications because it facilitates processes such as the dispersion of compounds, emulsification of immiscible liquids, and disruption of cellular structures.

Principles of Sonication:

- Sound Waves: Sonic waves generate rapid pressure changes in liquids, creating microscopic cavitation bubbles.

- Cavitation: These bubbles grow and implode violently, producing intense local heating and high shear forces.

- Effects: The energy from these implosions can break chemical bonds, mix substances, or clean surfaces.

Common Uses in Various Fields

Sonication is indispensable across various disciplines:

- Biology: Extraction of DNA, RNA, and proteins from cells.

- Chemistry: Speeding up reactions by enhancing chemical reactivity.

- Manufacturing: Homogenizing mixtures, such as paints and emulsions.

- Environmental Science: Degradation of pollutants in water.

Types of Sonicators

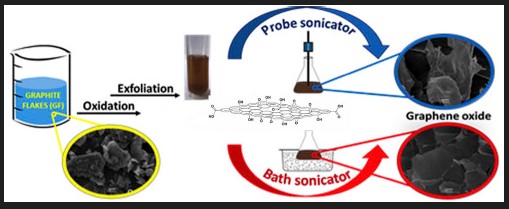

Overview of Probe Sonicators

A probe sonicator, also known as a direct sonicator, operates by immersing a probe directly into the sample. This device is especially effective for intensive disruption tasks like lysing cells or homogenizing tissues on a small scale.

Overview of Bath Sonicators

Bath sonicators function differently by immersing multiple samples, typically contained in test tubes or flasks, into a sonication bath filled with a fluid. This type is more suitable for less intensive tasks such as cleaning lab equipment or processing sensitive biological samples that require uniform treatment.

Probe Sonicators

Design and Operation

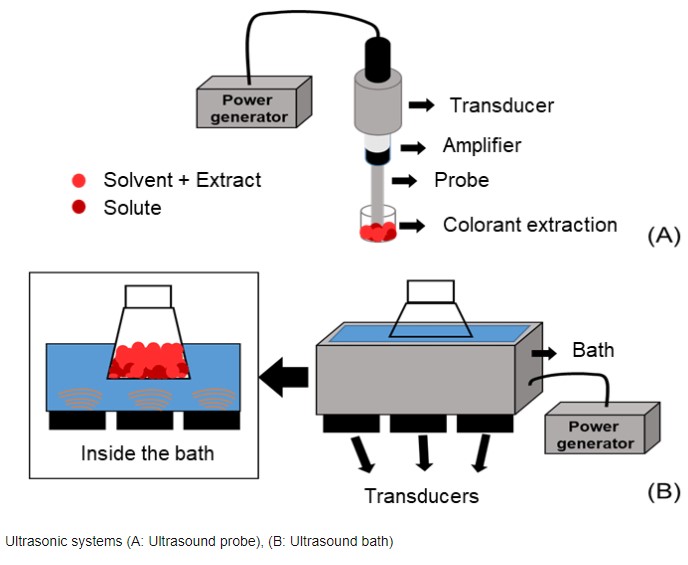

Components:

- Ultrasonic Generator: Produces high-frequency electrical signals.

- Transducer: Converts electrical signals into mechanical vibrations.

- Probe: Delivers vibrations directly to the sample.

Functionality:

- Intensity Control: Allows users to adjust the power level.

- Pulse Operation: Enables intermittent sonication to prevent heat buildup.

Typical Settings and Adjustments

- Amplitude: Adjusting the probe’s vibration intensity.

- Pulse Duration: Controlling the on/off cycle to manage temperature.

- Timer: Setting operation duration to ensure consistent results.

Applications

Laboratory Uses:

- Disrupting cellular membranes for extraction processes.

- Speeding up the reaction by enhancing molecular interactions.

Industrial Uses:

- Homogenizing food products.

- Processing materials in nanotechnology applications.

Advantages in Sample Processing

- Precision: Direct sonication offers precise control over the energy delivered to the sample.

- Efficiency: Rapid processing speeds up experimental and production timelines.

Limitations

Challenges and Drawbacks:

- Heat Generation: Can damage sensitive samples if not properly managed.

- Noise: High decibel levels require protective measures in lab settings.

Bath Sonicators

Design and Operation

Components:

- Water Bath: Contains the fluid that transmits sonic energy.

- Basket: Holds the samples securely during sonication.

Functionality:

- Temperature Control: Maintains a consistent fluid temperature.

- Frequency Adjustment: Tailors the sonic waves to different sample types.

Typical Settings and Adjustments

- Water Level: Ensures optimal transmission of sonic waves.

- Time Settings: Controls the duration of sonication to prevent over-exposure.

Applications

Cleaning Uses:

- Removing contaminants from laboratory glassware.

- Assisting in the decontamination of surgical instruments.

Processing Uses:

- Gentle mixing of pharmaceutical compounds.

- Activation of enzymes in biochemical assays.

Benefits for Delicate Samples

- Uniformity: Ensures even exposure of all parts of the sample to sonic waves.

- Gentleness: Minimizes physical stress to maintain sample integrity.

Limitations

Operational Challenges:

- Cleaning: Requires regular maintenance of the sonication bath.

- Less Control: Difficult to achieve the same intensity of sonication across all samples.

Comparison

Performance Differences

Efficiency Comparisons

When evaluating the efficiency of probe and bath sonicators, it’s crucial to consider the nature of the task at hand. Probe sonicators are highly efficient for direct, intensive applications such as cell disruption or nanoparticle dispersion, where localized, high-intensity energy is beneficial. In contrast, bath sonicators distribute energy more evenly, making them less efficient for tasks requiring concentrated energy but ideal for uniformly processing multiple samples or cleaning delicate instruments.

Effectiveness in Different Applications

Probe sonicators excel in applications requiring precise control over the sonication process, such as in the preparation of emulsions in pharmaceuticals or the breaking down of complex materials in research laboratories. Bath sonicators, on the other hand, are more effective for applications such as the degassing of liquids and cleaning of lab equipment, where gentle, consistent exposure to sonic waves is preferable.

Cost Implications

Initial and Maintenance Costs

Probe sonicators often carry a higher initial cost due to their sophisticated design and powerful output capabilities. They also tend to require more specialized maintenance given their complex mechanical and electronic components. Bath sonicators, while generally cheaper to purchase, involve costs related to the regular changing of the water and cleaning of the bath, which can add up over time.

Cost-Effectiveness for Various Uses

In terms of long-term investments, the choice between probe and bath sonicators should consider usage frequency and operational scope. For labs requiring high-throughput sample processing with minimal sample degradation, the bath sonicator may offer better cost-effectiveness. Conversely, for specialized applications demanding high precision, the probe sonicator may justify its higher cost through superior results and efficiency.

User Experience

Ease of Use and Safety Considerations

Bath sonicators are generally more user-friendly, especially for routine cleaning tasks or when handling fragile samples that could be damaged by direct sonication. They also tend to be safer, as they encapsulate the sonic action within a water bath, minimizing exposure to intense sound waves. Probe sonicators, while offering more control and power, require careful handling to avoid sample overheating and operator exposure to high noise levels.

Learning Curve and Training Requirements

Operating a probe sonicator effectively requires a deeper understanding of sonication principles and more thorough training, particularly to optimize settings like amplitude and pulse duration for different materials. Bath sonicators typically have a gentler learning curve, making them more accessible for routine use in educational and less specialized settings.

Case Studies

Real-world Application: Probe

Detailed Example in a Research Setting

In a recent study conducted at a leading biotechnological research institute, a probe sonicator was utilized to lyse bacterial cells for protein extraction. The process involved:

- Setting the Amplitude: Adjusted to 60% to ensure efficient cell disruption without overheating.

- Pulse On/Off Cycles: 5 seconds on, 10 seconds off, to maintain a low sample temperature.

- Total Duration: 15 minutes per sample, optimizing yield while preventing protein denaturation.

This precise control over the sonication parameters allowed researchers to maximize the yield of intact proteins, critical for subsequent analytical procedures.

Real-world Application: Bath

Detailed Example in a Cleaning Process

A dental clinic adopted bath sonication for the cleaning and sterilization of dental tools. The procedure implemented includes:

- Temperature Setting: Kept at 40°C to enhance cleaning efficiency without damaging the tools.

- Sonication Duration: 30 minutes to ensure thorough removal of debris and pathogens.

- Detergent Use: A mild enzymatic cleaner added to the water to assist in breaking down organic materials.

Frequently Asked Questions

How does a probe sonicator work?

A probe sonicator operates by emitting high-frequency sound waves directly into a sample via a probe that is typically immersed in the medium. This method is highly effective for processing solutions at a microscopic level, resulting in thorough mixing or disruption of cellular structures.

What are the typical uses of a bath sonicator?

Bath sonicators are commonly used for cleaning laboratory instruments and processing fragile biological samples that require gentle, uniform exposure to sound waves. They are also favored in situations where batch processing of samples is necessary.

Can probe sonicators be used for large volumes?

Probe sonicators are generally used for smaller sample volumes as their direct method allows for precise control over the sonication process. For larger volumes, multiple sessions or different types of equipment might be more appropriate.

What are the cost implications of using a bath sonicator?

Bath sonicators tend to be less expensive initially and are cost-effective for processing multiple samples simultaneously. However, they may require more frequent maintenance and use more energy compared to probe sonicators, especially under heavy use conditions.

Conclusion

Choosing between a probe and a bath sonicator should be guided by specific needs such as sample volume, sensitivity, and the desired intensity of sonication. Each type of sonicator offers unique advantages that can significantly affect the efficiency and outcome of scientific or industrial processes. It is essential to evaluate the operational requirements and constraints of each method to make an informed decision.

Ultimately, understanding the distinct capabilities and limitations of both probe and bath sonicators ensures optimal application and integration into various workflows. This knowledge not only enhances operational efficiency but also helps maintain the integrity and quality of the samples being processed, which is paramount in high-stakes environments.