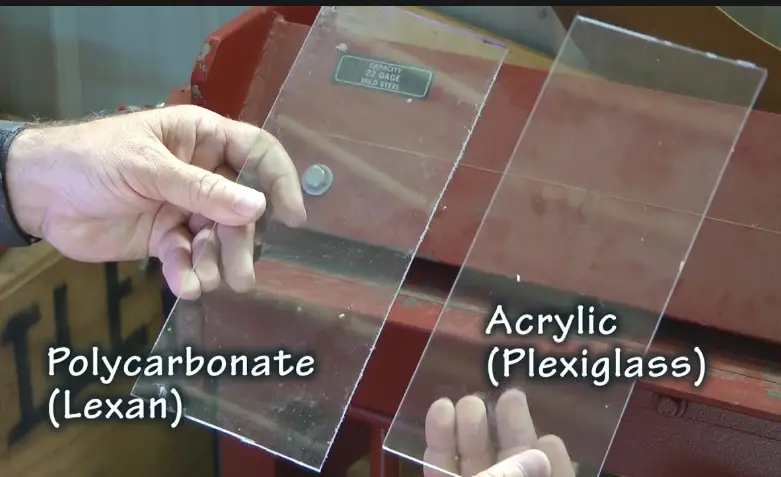

Polycarbonate and plexiglass are two prominent materials widely used across various industries, each possessing unique characteristics and benefits. While they often appear similar to the untrained eye, their distinct properties cater to different needs and applications. A thorough comparison of these materials is essential for anyone considering their use in projects or products.

Polycarbonate is a tough, transparent plastic known for its remarkable impact resistance and heat tolerance, making it ideal for applications requiring durability under stress. On the other hand, Plexiglass, which is a brand name for acrylic, offers excellent clarity and is more scratch-resistant than other plastic materials. It is often used where aesthetics are as important as functionality.

Both materials are celebrated for their versatility and performance in challenging environments. From bulletproof windows to lightweight eyewear lenses, polycarbonate and plexiglass continue to revolutionize industries by offering safe, durable, and cost-effective solutions.

Material Profiles

What is Polycarbonate?

Polycarbonate is a type of thermoplastic polymer that is notably strong and resistant to impact. This material is a part of the polyester family of plastics and features a unique combination of toughness with optical clarity, maintaining transparency while being able to withstand extreme forces. Polycarbonate’s ability to be molded into different shapes and its lightweight nature makes it a versatile choice for a wide range of applications, from bulletproof windows to compact discs.

What is Plexiglass?

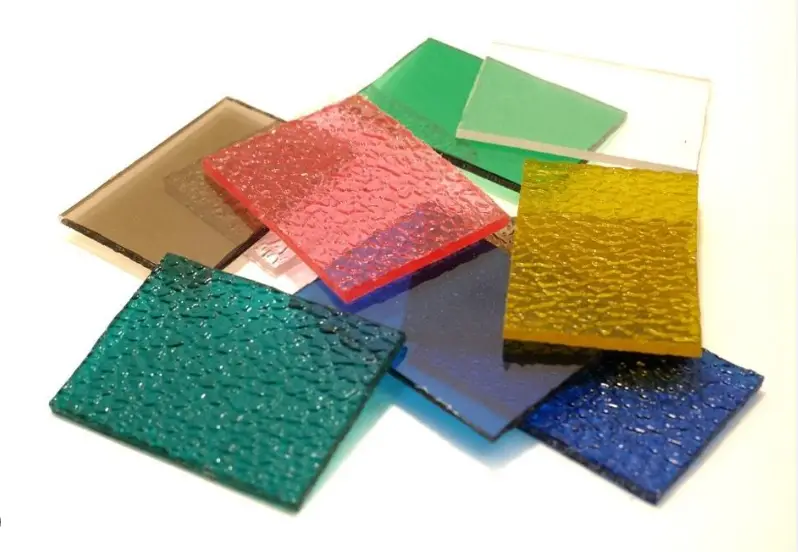

Plexiglass is the commercial name for polymethyl methacrylate (PMMA), commonly referred to as acrylic. This synthetic polymer is renowned for its clarity, being as transparent as the finest optical glass. Plexiglass is shatter-resistant, making it an excellent alternative to glass in areas where safety is a concern. Its ease of handling, cutting, and forming, along with its resistance to ultraviolet light and weathering, makes it popular in signage, window glazing, and displays.

Key Properties

Physical Characteristics

Polycarbonate is characterized by its resilience and strength, capable of bending without breaking. This flexibility makes it useful in applications requiring material that can withstand deformation without fracturing. Plexiglass, on the other hand, though less flexible than polycarbonate, offers greater scratch resistance and can be polished to restore its clear finish if needed.

Durability and Resistance

Both materials are durable, but polycarbonate excels in environments where impact resistance is critical. It can withstand massive forces and is often used in security installations, such as bank teller shields and police riot shields. Plexiglass, while not as tough against impacts, resists weather elements better, maintaining its clarity and resistance to yellowing under sunlight exposure.

Transparency and Light Transmission

Transparency is a hallmark of both materials. Polycarbonate allows about 88% of light to pass through, making it almost as clear as glass. Plexiglass transmits up to 92% of light, providing a clearer view than many types of glass. This property is particularly valuable in applications such as lenses and outdoor signs, where maximum light transmission is desired without sacrificing material integrity.

Production Process

How Polycarbonate is Made

- Bisphenol A and phosgene are reacted in a solution of sodium hydroxide.

- The resulting polymer is precipitated and washed.

- The polymer is then extruded into sheets or molded into shapes, depending on the intended use.

How Plexiglass is Manufactured

- Methyl methacrylate monomer is polymerized, either by batch cell or continuous process.

- The polymer slurry is cast into sheets or forms.

- The material is then thermally treated to improve its durability and to eliminate any residual stresses.

Cost Analysis

Pricing Factors

The cost of both polycarbonate and plexiglass is influenced by factors such as the raw material prices, production complexity, and the scale of manufacturing. Polycarbonate generally tends to be more expensive due to its superior performance characteristics and the complexity of its manufacturing process.

Comparative Cost Effectiveness

While polycarbonate is more costly, its durability and life span can make it a more cost-effective option in the long term for high-risk environments where material failure could lead to significant costs. Plexiglass, being cheaper, is cost-effective for projects where high impact resistance is not critical but optical clarity and resistance to weathering are valued.

Environmental Impact

Ecological Footprint

The ecological footprint of a material refers to the impact it has on the environment throughout its lifecycle, from extraction to disposal. Polycarbonate production requires the use of fossil fuels and generates greenhouse gas emissions, contributing to climate change. However, its durability and longevity can offset some of these environmental costs by reducing the need for frequent replacements.

Recycling and Sustainability

Both polycarbonate and plexiglass can be recycled, but the process is more common and efficient for plexiglass due to its simpler chemical composition. Recycling polycarbonate often involves complex separation processes, and the resulting recycled material may have reduced performance compared to virgin polycarbonate. However, advancements in recycling technologies are continually improving the sustainability of both materials.

Common Uses

Industrial Applications

Polycarbonate is favored in industrial settings for its exceptional strength and impact resistance. It is commonly used in manufacturing components for machinery, safety equipment such as protective goggles and helmets, and automotive parts like headlight lenses and interior trim.

Everyday Products

Plexiglass finds its way into numerous everyday products due to its optical clarity and versatility. From consumer electronics screens to aquariums and interior design elements, plexiglass offers a lightweight and shatter-resistant alternative to glass, enhancing safety without sacrificing aesthetics.

Advantages and Disadvantages

Benefits of Polycarbonate

- Exceptional Strength: Polycarbonate is virtually unbreakable, making it suitable for applications where impact resistance is crucial.

- High Transparency: Despite its strength, polycarbonate maintains excellent clarity, allowing for optimal light transmission.

- Weather Resistance: It withstands UV radiation and extreme temperatures, making it ideal for outdoor use.

Drawbacks of Polycarbonate

- Scratch Prone: Despite its toughness, polycarbonate is susceptible to scratching, which can affect its optical properties over time.

- Costly: The manufacturing process and raw material costs make polycarbonate more expensive than some other plastics.

- Limited Chemical Resistance: It may degrade when exposed to certain chemicals, limiting its suitability for some applications.

Benefits of Plexiglass

- Optical Clarity: Plexiglass offers exceptional transparency, rivaling that of glass, without the weight or fragility.

- Easy to Work With: It can be cut, drilled, and shaped with conventional tools, allowing for customization in various applications.

- UV Resistance: Plexiglass resists yellowing and degradation from UV radiation, maintaining its clarity over time.

Drawbacks of Plexiglass

- Brittleness: While plexiglass is shatter-resistant, it is more prone to cracking than polycarbonate when subjected to impact.

- Scratch Susceptibility: Despite its clarity, plexiglass is prone to scratching, requiring regular maintenance to preserve its appearance.

- Static Buildup: It can accumulate static electricity, attracting dust and requiring frequent cleaning in certain environments.

Maintenance and Care

Cleaning Guidelines

To maintain the clarity and longevity of both polycarbonate and plexiglass, follow these cleaning guidelines:

- Use a mild soap or detergent and lukewarm water to clean the surface.

- Avoid abrasive cleaners or scrubbers that could scratch the material.

- Rinse thoroughly and dry with a soft, lint-free cloth to prevent water spots.

Longevity Tips

- Apply a protective coating or film to reduce scratches and prolong the lifespan of the material.

- Avoid harsh chemicals or solvents that may degrade the surface of polycarbonate or plexiglass.

- Store and handle the materials with care to prevent damage during transportation or installation.

Industry Insights

Market Trends

The demand for polycarbonate and plexiglass continues to grow across various industries, driven by factors such as urbanization, infrastructure development, and the increasing emphasis on safety and sustainability. Advancements in manufacturing technologies and the introduction of new formulations are further fueling market growth.

Future Outlook

As environmental concerns become more prominent, the focus on sustainable materials and recycling initiatives will shape the future of the polycarbonate and plexiglass industries. Innovations in recycling processes and the development of bio-based alternatives offer promising opportunities to reduce environmental impact while meeting the growing demand for durable and transparent materials.

Frequently Asked Questions

What is Polycarbonate?

Polycarbonate is a robust, transparent plastic noted for its high impact resistance, making it suitable for products requiring durability and safety, such as bullet-proof glass and various outdoor applications.

What is Plexiglass?

Plexiglass, known chemically as polymethyl methacrylate (PMMA), is a clear acrylic plastic favored for its superior scratch resistance and clarity, commonly used in display cases, picture frames, and windows.

How do Polycarbonate and Plexiglass Differ?

While both materials are plastic and transparent, polycarbonate excels in impact resistance and heat tolerance, whereas plexiglass offers better scratch resistance and is easier to shape and mold.

Which is More Cost-Effective?

Generally, plexiglass tends to be less expensive than polycarbonate, but the choice between the two should consider the specific needs of the application, such as the required durability and visual qualities.

Can Polycarbonate and Plexiglass be Recycled?

Yes, both materials can be recycled. Polycarbonate is typically recycled into plastic lumber and other structural materials, while plexiglass can be broken down and repurposed into new acrylic sheets.

Conclusion

In conclusion, when selecting between polycarbonate and plexiglass, one must consider the specific requirements of their application. Polycarbonate offers unmatched toughness and heat resistance, suitable for environments where safety and durability are paramount. Plexiglass, with its superior clarity and resistance to weathering, is ideal for aesthetic applications where appearance is highly valued. Understanding these materials’ distinct properties enables informed decisions that ensure both practicality and cost-efficiency in their use.