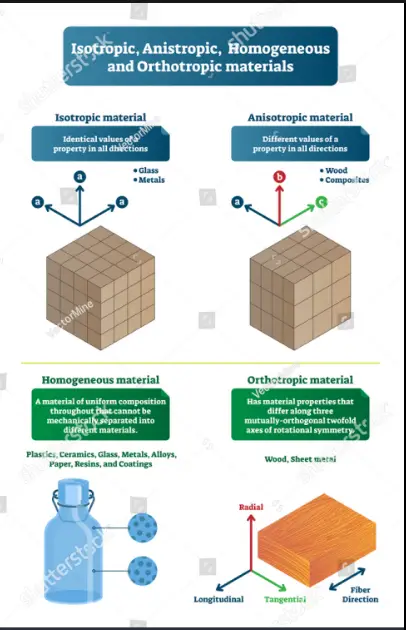

Materials science stands at the forefront of many technological breakthroughs, with its core focus on understanding different material properties essential for varied applications. Among the most crucial distinctions in this field are those between orthotropic and anisotropic materials, terms frequently encountered by engineers and designers. These categories describe how the properties of a material can vary depending on direction—a fundamental concept in creating efficient, durable, and innovative products.

Orthotropic materials have different properties in three mutually perpendicular directions, commonly found in natural and engineered materials like wood and composites. In contrast, anisotropic materials exhibit directional dependence of properties without the restriction to perpendicular axes, seen in crystals and certain synthetic creations. This distinction is vital for selecting the right material for specific engineering applications, affecting everything from durability to thermal conductivity.

Exploring these material types offers insights into their behavior under various conditions, such as mechanical stress and temperature changes. By understanding the inherent properties of these materials, engineers can better predict their performance in real-world applications, leading to more reliable and effective designs.

Basic Concepts

Orthotropic Materials

Definition and Examples

Orthotropic materials are those characterized by having unique and independent mechanical properties in three perpendicular axes. This anisotropy ensures that their physical properties vary when measured along different directions. Common examples include wood, where the material strength and stiffness differ along the grain compared to across or perpendicular to the grain. Engineered products like fiber-reinforced plastics and certain laminated composites also fall into this category, designed to exploit these directional properties for better performance in specific applications.

Key Properties

The key properties of orthotropic materials are primarily defined by their directional dependence. These properties include:

- Elastic modulus, which may vary significantly when measured along different axes.

- Strength, where for example, wood is stronger along the grain than across it.

- Thermal expansion, which can differ in the material’s length, width, and thickness.

These variations are critical for engineers to consider when designing products and structures, ensuring that the material orientation aligns with the expected loads and environmental conditions.

Anisotropic Materials

Definition and Examples

Anisotropic materials differ from orthotropic by having properties that change directionally but are not limited to perpendicular relationships. These materials can exhibit variations in physical characteristics from any direction of measurement. Common examples include metals like steel, where crystalline structures cause properties to vary. Crystals and layered graphene are other prime examples, each offering unique directional properties that are crucial in applications ranging from electronic components to thermal interfaces.

Key Properties

For anisotropic materials, the variance in properties such as electrical conductivity, magnetic permeability, and optical responses is not confined to orthogonal axes. This can be significantly advantageous in fields requiring precise control over material behavior under various operational scenarios. These properties include:

- Conductivity, often exploited in semiconductor and solar panel technologies where directional properties can influence performance.

- Permeability, crucial in magnetic applications where the orientation of material can impact the efficiency and effectiveness of a device.

Comparison of Properties

Structural Behavior

Response to Stress

Orthotropic materials tend to respond predictably along their principal axes, which can be leveraged to optimize structures against predictable loads. Anisotropic materials, however, offer a broader range of stress responses, which can be a double-edged sword—offering more flexibility but requiring more complex predictive models to ensure reliability.

Flexibility and Rigidity

The flexibility or rigidity of a material under load is fundamentally linked to its structural anisotropy. For example, engineered wood or composite beams can be designed to be more rigid along certain axes to support specific types of loads. In contrast, metals may be processed to enhance flexibility in certain directions without compromising overall strength, essential for components like springs and beams.

Thermal Characteristics

Heat Conduction Variations

The way heat is conducted through a material can greatly affect its applications. Orthotropic materials like certain composites are designed so that heat transfer is more efficient in one direction, which can be crucial for thermal management systems in electronics. Anisotropic materials offer varying heat conduction paths, which can be manipulated to create highly efficient heat sinks or insulating layers depending on the orientation of the material.

Applications Based on Thermal Properties

The specific thermal properties of orthotropic and anisotropic materials make them suitable for different applications:

- Orthotropic materials are often used in aerospace and automotive industries where directional thermal properties can help manage heat stress under operational conditions.

- Anisotropic materials find applications in electronic manufacturing, where controlled thermal conductivity can prevent overheating without additional cooling systems.

Practical Applications

Orthotropic Materials in Use

Industry Examples

Orthotropic materials are extensively used in industries where directional strength and stiffness are paramount. For instance, wood is utilized in construction due to its superior strength along the grain, making it ideal for beams and columns. Carbon fiber composites, another example, are prevalent in the aerospace sector. The fibers are aligned to bear loads effectively while minimizing weight, crucial for aircraft performance.

Advantages in Specific Applications

The structured orientation of properties in orthotropic materials allows for optimized performance in tailored applications. In the automotive industry, composite materials are designed to enhance safety and fuel efficiency by reducing weight while maintaining structural integrity. The advantages include:

- Enhanced load-bearing capabilities where needed

- Reduced material usage without compromising performance

- Improved energy efficiency due to lighter weight

Anisotropic Materials in Use

Industry Examples

Anisotropic materials find their use in more varied and technologically advanced applications. In electronics, silicon wafers are an excellent example. The directional properties of silicon allow for precise control over electrical conductivity, essential for semiconductor devices. Another key application is in the field of magnetics, where materials like cobalt-samarium offer superior performance in compact, high-strength permanent magnets.

Advantages in Specific Applications

The ability to tailor properties in anisotropic materials leads to significant advantages in high-tech applications:

- Electronic devices benefit from materials with controlled electrical pathways, improving the efficiency and size of devices.

- Optical systems use crystals with unique refractive properties to enhance the precision and quality of imaging systems.

Challenges and Solutions

Engineering Challenges

Working with orthotropic and anisotropic materials presents unique challenges, primarily related to predicting and managing the behavior of these materials under operational stresses.

Common Issues Faced

One of the main issues is the complexity of design needed to adequately predict and utilize the directional properties of these materials. Additionally, manufacturing consistency can be a challenge, as slight variations in process conditions can significantly alter material properties.

Solutions and Workarounds

Engineers have developed several solutions to overcome these challenges:

- Advanced simulation tools allow for accurate modeling of material behavior under various conditions, helping to predict performance before physical prototypes are built.

- Controlled manufacturing environments ensure consistent quality and properties in produced materials.

Research and Development

Recent Advancements

Recent advancements in the field of material science have led to enhanced understanding and utilization of both orthotropic and anisotropic materials. For instance, the development of 3D printing technologies allows for precise control over material orientation, opening up new possibilities for custom-designed materials with tailored properties.

Future Possibilities

The future of materials science holds promising potential for even greater control and exploitation of material properties. Researchers are exploring the possibilities of nano-engineering materials at an atomic level to achieve unprecedented performance characteristics. This could lead to breakthroughs in various fields, from medicine to quantum computing, where material properties are critical.

Frequently Asked Questions

What are Orthotropic Materials?

Orthotropic materials are those that have different properties in three mutually perpendicular directions. Common examples include wood, where properties like strength and elasticity differ along the grain, across the grain, and through the thickness of the material.

What are Anisotropic Materials?

Anisotropic materials exhibit properties that vary in response to the direction of the applied force or environmental condition, regardless of whether these directions are perpendicular. This behavior is typical in materials like crystals and certain metals, where the atomic alignment influences properties such as electrical conductivity and tensile strength.

How do Orthotropic and Anisotropic Materials Differ in Use?

The primary difference lies in their application suitability. Orthotropic materials are preferred in structured applications like aerospace and construction, where predictable directional properties are crucial. Anisotropic materials are favored in applications requiring varied properties from different angles, such as in electronics and optical devices.

Why is Material Directionality Important in Engineering?

Material directionality is crucial for predicting how materials behave under stress, heat, and other operational conditions. Understanding whether a material is orthotropic or anisotropic helps in designing more efficient and safer structures by aligning the material properties with the directional loads they will encounter.

Conclusion

The distinction between orthotropic and anisotropic materials is more than a technicality; it is a cornerstone of material science that impacts various fields of engineering and design. Recognizing these differences not only aids in the appropriate selection of materials but also enhances the performance and safety of the final products. As technology advances, the exploration of these materials continues to evolve, promising even greater insights and innovations in material science. By leveraging the unique properties of these materials, engineers can craft solutions that meet the increasing demands of modern applications, marking a significant step forward in the development of new technologies and products.