Crystalline materials are integral to a multitude of applications, ranging from everyday electronics to sophisticated aerospace components. Their unique properties and structures make them critical in advancing technology and enhancing product functionalities. The distinction between nanocrystalline and polycrystalline materials, while subtle, has significant implications for their use and performance.

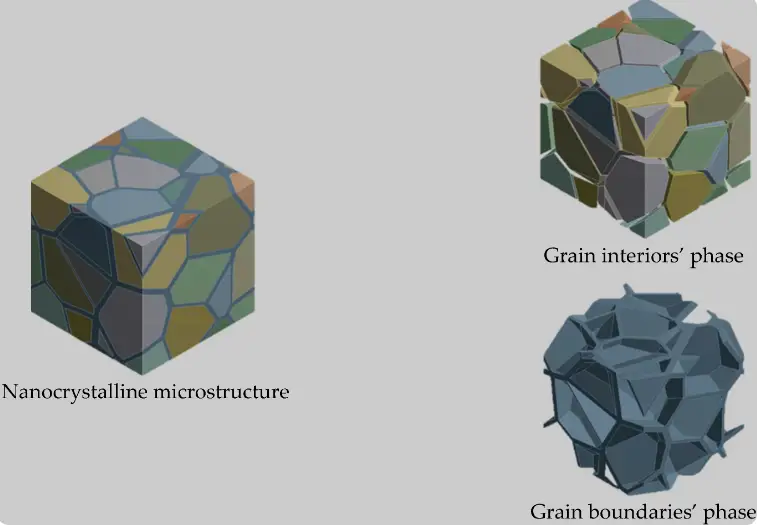

Nanocrystalline materials are characterized by their ultra-fine grain size, typically less than 100 nanometers. Polycrystalline materials, on the other hand, consist of larger, randomly oriented crystals. This fundamental difference in grain size affects their mechanical, electrical, and optical properties, making each suitable for specific applications.

Exploring these materials reveals that their differences extend beyond size, influencing how they are produced, their durability, and their suitability for various industrial uses. Their diverse capabilities enable innovations across a broad spectrum of science and engineering fields, enhancing both existing and emerging technologies.

Basic Concepts

Definition of Crystals

Crystals are solid materials whose constituents, such as atoms, molecules, or ions, are arranged in a highly ordered microscopic structure. This formation results in a crystal lattice that extends in all directions. The precise nature of the lattice, despite its microscopic scale, significantly impacts the material’s properties.

Crystalline vs. Amorphous Structures

Crystalline materials boast an orderly arrangement where the patterns are repeated over long ranges. Amorphous materials, by contrast, lack this order and are characterized by a disorganized arrangement of atoms. This difference in structural organization affects the materials’ properties:

- Transparency: Crystalline materials often are transparent, while amorphous ones may be opaque.

- Strength and Durability: The structured nature of crystalline materials often results in higher strength and durability compared to their amorphous counterparts.

- Melting Point: Crystalline structures generally have well-defined melting points, unlike amorphous materials that soften over a range of temperatures.

Nanocrystalline Materials

Definition and Characteristics

Nanocrystalline materials consist of grains smaller than 100 nanometers. Due to their minuscule grain size, these materials exhibit unique physical and chemical properties:

- Increased Strength: Smaller grain sizes result in a higher surface area to volume ratio, which can significantly enhance the material’s strength.

- Enhanced Reactivity: The increased surface area also enhances the chemical reactivity, making nanocrystalline materials ideal for catalysis.

Formation and Synthesis

The production of nanocrystalline materials involves several methods:

- Chemical Vapor Deposition (CVD): A process where chemicals react to form a fine powder of the target material.

- Ball Milling: Mechanical forces are used to break down bulk materials into nanocrystalline forms.

- Sol-Gel Techniques: Starting from a colloidal solution that forms an integrated network upon gelation.

Polycrystalline Materials

Definition and Characteristics

Polycrystalline materials are composed of multiple crystalline grains randomly oriented. They are characterized by:

- Grain Boundaries: The interfaces between individual grains can impact electrical and thermal conductivity.

- Versatility: These materials are commonly used in various applications due to their general robustness.

Formation and Synthesis

Polycrystalline materials can be synthesized through:

- Solidification: This process involves cooling a liquid until it solidifies, forming multiple crystals of varying sizes and orientations.

- Sintering: Powdered materials are pressed and heated below their melting point to form a solid mass.

Key Differences

Grain Size

- Nanocrystalline: Typically less than 100 nanometers.

- Polycrystalline: Grain sizes can range from a few hundred nanometers to several millimeters.

Physical Properties

The small grain size in nanocrystalline materials results in properties such as:

- Higher Hardness and Toughness: Due to a large number of grain boundaries, which impede the movement of dislocations.

- Distinct Optical Properties: The reduced size can affect the way light interacts with the material, often leading to unique optical properties.

Chemical Properties

- Increased Surface Reactivity: Nanocrystalline materials’ larger surface area to volume ratio enhances their chemical reactivity.

- Catalytic Efficiency: Their nano-size enables superior performance in catalytic applications due to more active sites and shorter diffusion paths.

Applications

Nanocrystalline Applications

Nanocrystalline materials are pivotal in various high-tech applications due to their enhanced properties. Here are some key areas where they are used:

- Electronics: These materials are used in the manufacture of microchips and semiconductors. Their small grain size allows for more compact and efficient components.

- Catalysis: Nanocrystalline materials are effective catalysts in chemical reactions due to their high surface area, enhancing the rate of chemical processes.

- Energy Storage: They are employed in batteries and supercapacitors for energy storage and conversion applications, improving energy density and charge-discharge cycles.

Polycrystalline Applications

Polycrystalline materials are also widely used in several fields:

- Solar Panels: They are commonly used in the production of photovoltaic cells because they offer a cost-effective alternative to monocrystalline silicon cells.

- Metallurgy: Polycrystalline metals and alloys are essential in building and construction for structural applications due to their overall strength and durability.

- Ceramics: Used in various applications from tableware to advanced ceramics in aerospace engineering.

Advantages and Limitations

Benefits of Nanocrystalline

- High Strength and Hardness: The fine grain structure of nanocrystalline materials leads to exceptional strength and hardness, making them suitable for advanced engineering applications.

- Enhanced Electrical Properties: These materials often exhibit superior electrical properties which are crucial in the electronics industry.

- Improved Wear Resistance: Their resistance to wear and erosion makes them ideal for protective coatings and high-wear environments.

Benefits of Polycrystalline

- Cost-Effectiveness: Polycrystalline materials are generally less expensive to produce than their single-crystal counterparts, making them more accessible for a variety of applications.

- Thermal Resistance: These materials can withstand significant temperature variations, making them ideal for high-temperature applications.

- Versatility: They can be used across a broad range of industries, adding to their practicality and utility.

Challenges and Limitations

- Grain Boundaries in Polycrystalline Materials: These can be sites of weakness where cracks initiate, leading to potential failures under stress.

- Size Limitation in Nanocrystalline Materials: While the small size of nanocrystals offers advantages, it can also lead to difficulties in handling and manufacturing on an industrial scale.

- Oxidation and Corrosion: Both nanocrystalline and polycrystalline materials can be susceptible to oxidation and corrosion depending on the environment in which they are used.

Future Prospects

Innovations in Material Science

The future of material science promises significant advancements with the integration of nanocrystalline and polycrystalline materials. Innovations include:

- Self-healing Materials: Research is ongoing into creating materials that can repair themselves using the properties of finely structured crystals.

- Environmentally Friendly Materials: Development of new materials that reduce environmental impact and are more sustainable.

Emerging Technologies

- Quantum Computing: Nanocrystalline materials may play a critical role in the development of quantum computers by providing essential components that operate at the quantum level.

- Flexible Electronics: The development of flexible electronic devices, such as bendable screens and wearable technology, benefits greatly from the flexible properties of polycrystalline materials.

- Advanced Photovoltaics: Both nanocrystalline and polycrystalline materials are key to advancing solar technology, improving efficiency and reducing costs in solar energy systems.

Frequently Asked Questions

What are crystalline materials?

Crystalline materials are solids that have a highly ordered structure, with atoms arranged in a repeating pattern. This arrangement gives them unique physical properties such as high strength and excellent electrical conductivity.

How are nanocrystalline materials synthesized?

Nanocrystalline materials are typically synthesized using techniques like gas condensation, electrodeposition, and mechanical milling, which allow precise control over their microstructure and properties.

What makes polycrystalline materials different from single crystals?

Polycrystalline materials are composed of multiple crystalline grains, which are randomly oriented, unlike single crystals that have a continuous and unbroken lattice structure across the entire sample.

Why are nanocrystalline materials preferred in some applications?

Nanocrystalline materials are preferred for applications requiring high strength and durability in small form factors due to their fine grain structure, which significantly improves hardness and wear resistance.

Can polycrystalline materials be used in electronics?

Yes, polycrystalline materials are widely used in electronics, especially in solar panels, where they provide a cost-effective alternative to single-crystal silicon without significantly compromising efficiency.

Conclusion

The intricate distinctions between nanocrystalline and polycrystalline materials play a pivotal role in their selection for specific applications. The choice between these two types of materials depends on factors such as required strength, durability, and conductivity, tailored to meet the demands of various technological applications.

Understanding their unique properties and the methods of their production helps in optimizing material selection for enhanced performance and sustainability in numerous fields. As technology evolves, the relevance and utilization of both nanocrystalline and polycrystalline materials are expected to grow, driven by ongoing research and innovation.