Manganese dioxide (MnO2) and copper(II) oxide (CuO) stand as pivotal compounds in the vast landscape of inorganic chemistry, each harboring unique properties and a multitude of applications across various industries. These materials, central to technological advancements and environmental solutions, exhibit distinctive physical and chemical behaviors that set them apart from one another and from other compounds.

MnO2 and CuO differ primarily in their chemical composition, physical properties, and the roles they play in industrial applications. MnO2, a black or brown solid, is widely used in batteries, water treatment, and as a catalyst. CuO, a black powder, finds its applications in electronics, catalysis, and pigments. These variations underline the importance of understanding each compound’s unique attributes and applications.

The significance of MnO2 and CuO extends beyond their immediate industrial use, influencing technological innovations, environmental conservation efforts, and the global economy. Their role in advancing energy storage solutions, purifying water, and catalyzing chemical reactions underscores the critical need for a deeper exploration of these materials. This article aims to shed light on the differences between MnO2 and CuO, highlighting their properties, applications, and the impact they have on our daily lives and future technological developments.

Basic Properties

MnO2 Properties

Physical Characteristics

Manganese dioxide (MnO2) is a dark-colored compound ranging from brown to black. It naturally forms as a solid with a crystalline structure that is significant in various technological applications due to its physical robustness. Notably, MnO2 has a density of approximately 5.03 g/cm³, which contributes to its wide use in heavy-weight applications such as battery cathodes.

Chemical Behavior

Chemically, MnO2 is known for its oxidizing properties, making it an essential component in reactions requiring electron transfer. It is relatively stable in air and water but reacts with acids to produce manganese salts and water, showcasing its versatile role in chemical processes.

CuO Properties

Physical Characteristics

Copper(II) oxide (CuO) is recognized by its distinctive black color and powdery texture. It possesses a monoclinic crystal structure, contributing to its unique physical properties, including a high melting point around 1326°C. With a density of 6.31 g/cm³, CuO is heavier than many other metal oxides, which plays a crucial role in its applications in heavy industries.

Chemical Behavior

CuO is a p-type semiconductor material, showing significant importance in electronic applications due to its ability to conduct electricity under certain conditions. It reacts with acids to form copper salts and water and can also act as a catalyst in various chemical reactions, emphasizing its reactive flexibility.

Production Methods

MnO2 Synthesis

Natural Occurrence and Extraction

MnO2 is commonly found in the environment as the mineral pyrolusite, which is the most significant ore for manganese mining. The extraction process involves:

- Mining the ore

- Crushing it to increase surface area

- Leaching with sulfuric acid to extract manganese dioxide

Laboratory Synthesis

Producing MnO2 in the lab can be achieved through several methods, including:

- Oxidizing manganese(II) chloride with potassium permanganate

- Using electrolysis to oxidize manganese compounds

These methods allow for the production of high-purity MnO2, suitable for specific research and industrial applications.

CuO Synthesis

Natural Occurrence and Extraction

Copper(II) oxide is found in the mineral tenorite. The extraction process for CuO generally involves:

- Mining copper ore

- Concentrating the ore via crushing and flotation

- Roasting copper sulfide ores to convert them into oxides

- Reducing the copper(II) oxide to copper metal

Laboratory Synthesis

In the laboratory, CuO can be synthesized by:

- Heating copper(II) nitrate, which decomposes into CuO, nitrogen dioxide, and oxygen

- Directly oxidizing copper in the presence of air at high temperatures

These processes allow for controlled production of CuO, enabling its use in a wide range of research and development activities.

Applications

MnO2 Uses

In Batteries

MnO2 is a key component in alkaline and zinc-carbon batteries, serving as the cathode material. Its ability to undergo reduction-oxidation reactions efficiently makes it ideal for use in batteries, offering high energy density and stability.

In Water Treatment

Manganese dioxide is used in water treatment plants to remove iron and manganese from water. Its oxidizing properties allow it to convert dissolved iron and manganese into insoluble forms, which can be easily filtered out, improving water quality.

As a Catalyst

MnO2 serves as a catalyst in organic synthesis, particularly in oxidation reactions. Its role in the synthesis of various chemicals showcases its versatility and effectiveness in speeding up chemical processes without being consumed.

CuO Uses

In Electronics

Copper(II) oxide is widely used in semiconductor devices and solar cells. Its semiconducting properties make it valuable in the electronics industry, contributing to the development of efficient and compact electronic devices.

In Catalysis

CuO is involved in catalyzing reactions in the production of methanol and synthetic fuels. Its ability to facilitate chemical reactions makes it a critical component in the chemical industry, particularly in processes aiming for green and sustainable chemistry.

In Pigments

Copper oxide finds its use in the creation of glass and ceramics, imparting green, blue, and black colors to the materials. Its application in pigments demonstrates its role in both aesthetic and functional aspects of materials science.

Chemical Reactions

Reactivity with Acids

MnO2 Reaction Specifics

Manganese dioxide (MnO2) reacts with hydrochloric acid (HCl) to produce manganese chloride (MnCl2), chlorine gas (Cl2), and water (H2O). This reaction highlights MnO2’s role as an oxidizing agent, capable of liberating chlorine from hydrochloric acid. This property is essential in applications such as water treatment and bleach production.

CuO Reaction Specifics

Copper(II) oxide (CuO) reacts with sulfuric acid (H2SO4) to form copper sulfate (CuSO4), and water. CuO’s reactivity with acids is a cornerstone in its use in copper extraction and recovery processes. This reaction showcases CuO’s role in producing valuable copper compounds for various industrial applications.

Role in Redox Reactions

As Oxidizing Agents

Both MnO2 and CuO act as oxidizing agents in redox reactions, participating in the transfer of electrons from one species to another. Their ability to accept electrons makes them crucial in chemical synthesis, energy storage, and environmental remediation processes.

Comparison of Reactivity

- MnO2 is particularly effective in reactions requiring the liberation of oxygen or other gases, used extensively in battery technology and chemical synthesis.

- CuO shows a strong ability to catalyze reduction reactions, especially in the formation of copper compounds and in applications requiring electrical conductivity.

Environmental Impact

MnO2 Impact

Toxicity and Safety Measures

MnO2 is generally considered low in toxicity but requires handling precautions to avoid inhalation or prolonged skin contact. In industrial settings, protective gear and adequate ventilation are necessary to mitigate exposure risks.

Environmental Benefits

MnO2 contributes positively to the environment by enhancing water purification processes and air quality through its use in filters and catalytic converters, reducing harmful emissions and contaminants.

CuO Impact

Toxicity and Safety Measures

Copper(II) oxide poses greater environmental and health risks compared to MnO2. Handling CuO requires stringent safety measures, including protective clothing and equipment, to prevent exposure and environmental release.

Environmental Benefits

Despite its toxicity, CuO is beneficial in catalyzing reactions that are crucial for environmental remediation. Its use in solar energy conversion also contributes to renewable energy solutions, offsetting carbon emissions.

Technological Advancements

MnO2 Innovations

Recent Studies and Applications

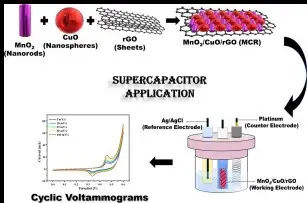

Recent advancements in MnO2 technology focus on enhancing its efficacy in energy storage systems, like supercapacitors and batteries. Studies explore its potential in flexible electronics, promising innovations in wearable technology and electronic devices.

CuO Innovations

Recent Studies and Applications

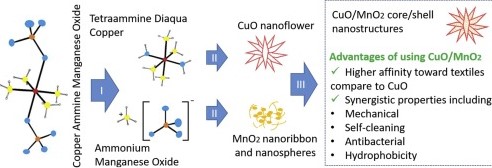

Innovation in CuO use spans nanotechnology and photocatalysis, aiming to leverage its properties for more efficient solar cells and environmental cleanup. Recent research explores CuO nanoparticles for antibacterial applications and water treatment solutions.

Cost and Availability

Market Trends

The demand for MnO2 and CuO has been increasing, driven by their versatile applications. The market trends indicate a growing interest in materials that support sustainable technologies and environmental solutions.

Pricing Comparison

- MnO2 is generally more affordable than CuO, reflecting its abundant availability and lower production costs.

- CuO, due to its specific applications and processing requirements, tends to be pricier, particularly for high-purity forms used in electronics and nanotechnology.

Availability in the Market

- MnO2 is widely available due to its abundant natural occurrence and relatively simple extraction and synthesis processes.

- CuO‘s availability is also high, but the market is more sensitive to changes in copper prices and demand for copper in other applications.

Frequently Asked Questions

What makes MnO2 unique in applications?

MnO2 is particularly valued for its role in dry cell batteries and water purification systems. Its unique electrochemical properties enable it to act as an excellent electron acceptor, making it a key component in alkaline batteries. Additionally, MnO2’s ability to adsorb contaminants from water attributes to its widespread use in water treatment processes.

How is CuO used in electronics?

CuO is utilized in electronics primarily for its semiconducting properties. It serves as a critical component in the production of semiconductors, transistors, and solar cells. The compound’s ability to conduct electricity under certain conditions makes it indispensable in the creation of electronic circuits and devices.

What are the environmental impacts of MnO2 and CuO?

Both MnO2 and CuO have environmental implications that vary based on their application and disposal. MnO2 is generally considered less toxic and can contribute positively to environmental remediation efforts, especially in water treatment. CuO, while useful in many applications, poses greater risks due to its toxicity to aquatic life and potential to cause environmental harm if not properly managed.

Can MnO2 and CuO be synthesized in the laboratory?

Yes, both MnO2 and CuO can be synthesized in the laboratory through various chemical reactions. MnO2 is often produced by the oxidation of manganese compounds, while CuO can be synthesized by heating copper in the presence of oxygen. These processes allow for the production of high-purity compounds for research and industrial applications.

Conclusion

The exploration of MnO2 and CuO reveals a fascinating contrast between two compounds that are integral to modern science and industry. Their distinct properties, coupled with their wide range of applications, not only underscore the versatility of inorganic compounds but also their potential to drive technological and environmental advancements. As we delve deeper into their characteristics and uses, we uncover the immense value these materials bring to our world, from enhancing battery technology to purifying our water sources.

The future holds great promise for the continued exploration and utilization of MnO2 and CuO, as researchers strive to unlock new applications and improve existing technologies. Their role in shaping a sustainable and technologically advanced future cannot be overstated, making the study of their differences and similarities more than just an academic pursuit but a pathway to innovation and environmental stewardship.