Gravimetric and volumetric feeders are both important pieces of equipment used in a variety of industries. This blog post will discuss the differences between the two, as well as their advantages and disadvantages. We will also look at how each type of feeder works and the types of materials that can be fed using these methods.

By the end of this post, readers will have a better understanding of the different types of feeders and how they can be used to meet the needs of their particular application.

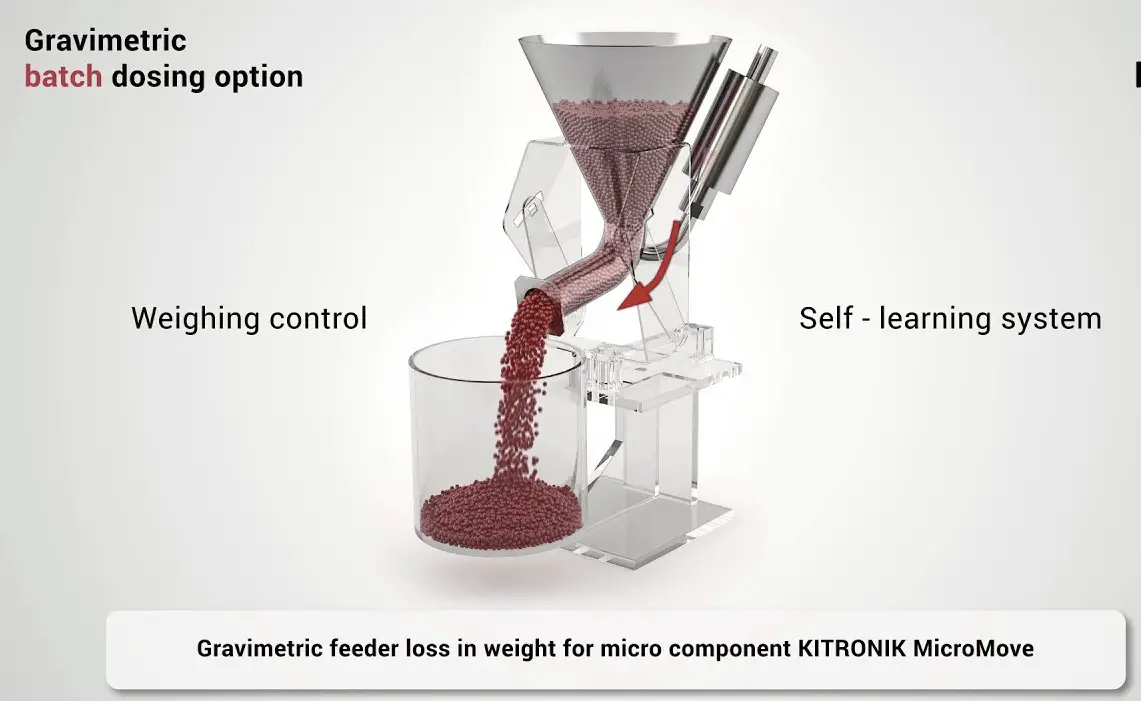

A gravimetric feeder

A gravimetric feeder is a device that precisely dispenses a predetermined amount of material, such as powdered solids, granules, and liquids. Unlike a volumetric feeder, which dispenses a fixed volume of material, a gravimetric feeder uses the weight of the material to determine the amount of material to be dispensed. This allows for more precise control of the amount of material dispersed.

Additionally, gravimetric feeders are often used in applications where accuracy is paramount, such as in pharmaceutical and chemical processes.

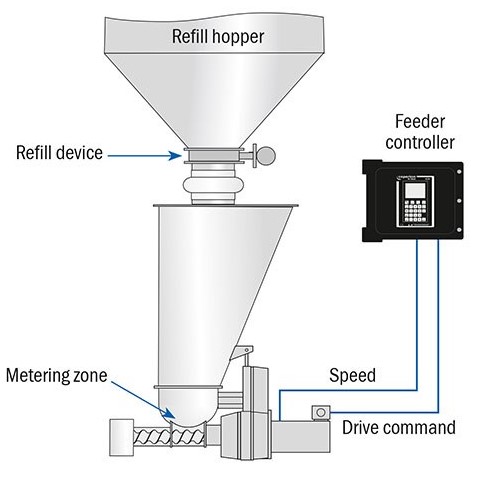

A volumetric feeder

A volumetric feeder is an essential piece of equipment used in many industries for a variety of purposes. It’s designed to accurately and reliably dispense a predetermined amount of material, sometimes over a period of time.

This makes it a great choice for applications where precise amounts of materials need to be delivered in an efficient manner. The key difference between a gravimetric and volumetric feeder is that the former relies on weight measurements while the latter uses volume measurements. A volumetric feeder is generally used when more accuracy is required in the amount of material fed, such as when working with fine powders or liquid materials.

It’s also a more reliable option for long-term applications, since it eliminates the need for frequent calibration of scales.

Comparison of gravimetric and volumetric feeders

The main difference between gravimetric and volumetric feeders lies in the way they measure and dispense materials. A gravimetric feeder measures and dispenses material according to its weight, while a volumetric feeder measures and dispenses material according to its volume.

Gravimetric feeders are typically used in applications that require precise and accurate feeding of a material, while volumetric feeders are usually used when a consistent, predictable and repeatable output is desired. Both types of feeders can be used in a variety of materials handling applications, but they each have their own advantages and disadvantages that need to be taken into consideration when selecting the right feeder for a particular application.

Advantages of gravimetric feeders

Gravimetric feeders are ideal for applications that require precise and consistent material flow. Unlike volumetric feeders, gravimetric feeders measure the actual weight of the material being dispensed, providing accurate and repeatable results. This makes them ideal for a variety of applications, including pharmaceutical, chemical, food and beverage, and powder metallurgy.

With gravimetric feeders, you can more accurately control the rate of material flow and the accuracy of the end product. This makes them ideal for processes that require exact measurements of the material being dispensed.

Additionally, gravimetric feeders are designed to be more efficient than volumetric feeders, resulting in less waste and higher throughput. Finally, they are less prone to clogging, meaning that your production process will be less prone to downtime.

Advantages of volumetric feeders

Gravimetric and volumetric feeders are two types of feeders used in industrial processes. Both have their advantages and disadvantages, and understanding the difference between them can help you decide which one is right for your application. Gravimetric feeders measure the weight of the material being fed, while volumetric feeders measure the volume of the material.

Gravimetric feeders measure the weight of the material being fed, while volumetric feeders measure the volume of the material. Gravimetric feeders are ideal for applications that require precise control of the material’s weight, while volumetric feeders are better suited for applications that require accurate delivery of material in a controlled volume. In general, volumetric feeders are more efficient and economical than gravimetric feeders.

They can also handle a variety of materials, including powders, granules, and liquids, with ease. Volumetric feeders are also more reliable, as they are less prone to material buildup and blockages.

Ultimately, the main difference between gravimetric and volumetric feeders lies in their accuracy and cost-effectiveness.

Final Touch

In conclusion, gravimetric and volumetric feeders are two different types of metering devices used to provide a controlled amount of material to a process. Gravimetric feeders measure the weight of material while volumetric feeders measure the volume of material.

Volumetric feeders, on the other hand, are simpler and require less maintenance. Both types of feeders are used in a variety of industries and applications, and the choice of which type to use depends on the requirements of the process.