Glyptal and Dacron are two synthetic materials widely recognized for their distinct chemical properties and versatile applications across various industries. Initially developed for specific industrial needs, these materials have evolved to become fundamental components in numerous products and manufacturing processes. Each has unique attributes that make it suitable for different environments and requirements.

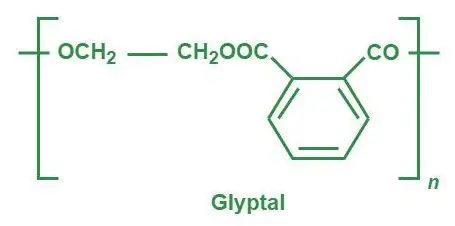

Glyptal, primarily used as an insulating varnish for electric coils, is a polymer made from the reaction between glycerol and phthalic anhydride. Dacron, on the other hand, is a type of polyester known for its strength, durability, and resistance to stretching and shrinking. These materials serve critical roles in everything from electrical engineering to textile production.

The distinction between Glyptal and Dacron lies in their chemical composition, production processes, and resultant physical properties. Glyptal is celebrated for its excellent electrical insulation properties, while Dacron is favored in textiles due to its high tensile strength and durability. Understanding these differences is essential for choosing the right material for specific applications, ensuring optimal performance and longevity.

Glyptal Overview

Definition and Chemical Composition

Glyptal is a type of alkyd resin formed from the esterification of phthalic anhydride and glycerol. This synthetic polymer is known for its excellent adhesion and film-forming properties. It is primarily used as an insulating and protective varnish in electrical applications.

Historical Development and Uses

Glyptal was developed in the early 20th century by General Electric as an insulator for electrical coils and components. Its invention was pivotal in improving the longevity and safety of electrical machines. Over the years, Glyptal has been used in a variety of applications beyond electrical insulation, including as a protective coating for metals against corrosion, and in automotive engines to reduce oil leaks and improve airflow.

Dacron Overview

Definition and Properties

Dacron, commercially known as polyethylene terephthalate (PET), is a polyester known for its strength, resistance to stretching and shrinking, and quick-drying properties. It is lightweight and extremely durable, which makes it a favorite in both textiles and non-textile industries.

Applications in Various Industries

Dacron’s versatility allows it to be used in a wide range of products including clothing, ropes, conveyor belts, and sails for boats. It is also commonly found in home furnishings such as curtains, upholstery, and bedding due to its durability and resistance to abrasions.

Production Processes

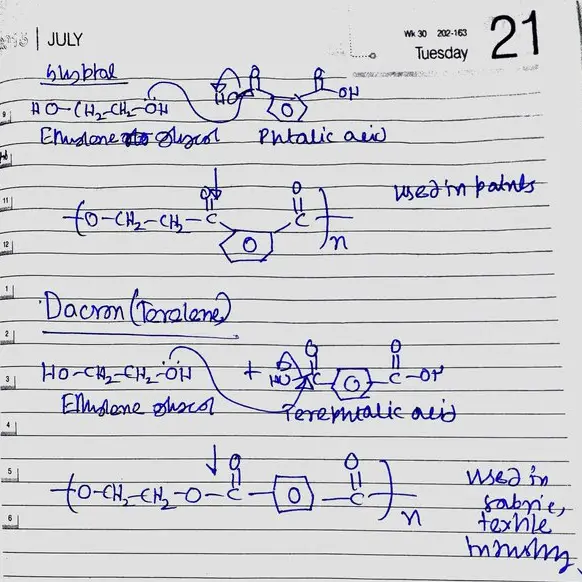

Glyptal Manufacturing Steps

- Esterification Reaction: Phthalic anhydride and glycerol are heated together to form a monoglyceride.

- Polyesterification: The monoglyceride undergoes further reaction under heat to form a polyester resin.

- Additives Incorporation: Various additives are blended into the resin to enhance its properties, depending on the intended application.

Dacron Production Techniques

- Polymerization: Ethylene glycol and terephthalic acid are polymerized to form a polyester.

- Melting and Extrusion: The polymer is melted and extruded through a spinneret to form fibers.

- Drawing and Heat Setting: The fibers are then stretched and heat-treated to achieve the desired strength and dimensional stability.

Physical Properties

Thermal Properties of Glyptal

Glyptal exhibits excellent thermal stability, which makes it suitable for use in high-temperature environments. It can withstand temperatures up to about 120°C without degrading, which is essential for its applications in electrical insulation.

Durability and Strength of Dacron

Dacron is highly valued for its tensile strength and durability. These properties ensure that products made from Dacron can withstand mechanical stresses and prolonged use without significant wear and tear, making it ideal for outdoor and marine applications.

Chemical Characteristics

Resistance to Chemicals in Glyptal

Glyptal is resistant to most solvents, oils, and alkalis, which allows it to serve effectively as a protective coating in various industrial applications, safeguarding materials from chemical corrosion.

Dacron’s Reaction to Environmental Factors

Dacron is generally resistant to most chemicals; however, it can be vulnerable to acidic environments which may cause hydrolysis of the fibers. Despite this, its overall chemical resistance contributes significantly to its longevity in harsh environments.

Common Uses

Industrial Applications of Glyptal

- Electrical Insulation: Used in motors, transformers, and other electrical components.

- Corrosion Protection: Applied on metal surfaces to prevent rust and corrosion.

Everyday Uses of Dacron

- Textiles: Used in clothing for its wrinkle-resistant properties.

- Home Furnishings: Utilized in draperies and carpets where durability is required.

Advantages and Limitations

Benefits of Glyptal in Industrial Settings

Glyptal resin offers several key benefits in industrial applications:

- Electrical Insulation: Its primary use as an electrical insulator helps prevent short circuits and malfunctions in various electrical devices.

- Chemical Resistance: Glyptal’s resistance to chemicals makes it ideal for use as a protective coating on industrial machinery and automotive parts.

- Thermal Resistance: The resin’s ability to withstand high temperatures enhances the durability and lifespan of components it coats.

Advantages of Dacron in Textiles

Dacron polyester is highly valued in the textile industry for its distinct advantages:

- Durability: Known for its strength and durability, Dacron extends the life of clothing and other textile products.

- Moisture Resistant: Its ability to repel water and dry quickly makes it suitable for outdoor and sportswear.

- Ease of Care: Dacron fabrics are wrinkle-resistant and maintain their shape, reducing the need for frequent ironing.

Limitations of Each Material

Despite their benefits, both materials have limitations:

- Glyptal:

- UV Sensitivity: Glyptal degrades when exposed to UV light, limiting its outdoor use without additional protective coatings.

- Brittleness: Over time, Glyptal can become brittle, particularly in cold environments, which may lead to cracking.

- Dacron:

- Environmental Concerns: As a synthetic, non-biodegradable fiber, Dacron contributes to environmental pollution if not properly recycled.

- Heat Sensitivity: Dacron can melt or deform at high temperatures, affecting its use in applications requiring heat resistance.

Environmental Impact

Glyptal’s Ecological Footprint

The production and use of Glyptal have notable environmental impacts:

- VOC Emissions: Glyptal varnishes release volatile organic compounds (VOCs) during application and drying, contributing to air pollution.

- Energy Intensive Production: The manufacturing process is energy-intensive, adding to its carbon footprint.

Dacron’s Recyclability and Sustainability

Dacron’s approach to environmental challenges includes:

- Recycling Programs: Dacron polyester is increasingly being recycled, turning old textiles into new products and reducing landfill waste.

- Sustainable Practices: Advances in production technology are reducing the water and energy consumption needed to produce Dacron, enhancing its sustainability profile.

Market Trends

Demand Trends for Glyptal

Glyptal continues to see demand in specific sectors:

- Electrical and Automotive Industries: Its use in electrical insulation and as a protective coating in automotive applications drives consistent demand.

- Renewable Energy Sector: Glyptal’s insulating properties are beneficial in solar panels and wind turbines, aligning with the growth in renewable energy initiatives.

Growing Uses of Dacron in the Market

Dacron’s market presence is expanding due to its versatile applications:

- Sportswear and Outdoor Gear: Its durability and moisture resistance make it ideal for sportswear and outdoor equipment.

- Home Furnishings: Dacron’s use in home textiles is growing due to its longevity and ease of maintenance.

Future Perspectives

Innovations in Glyptal Applications

Research is focused on overcoming Glyptal’s limitations and enhancing its applications:

- UV Resistant Formulas: Development of UV-stable Glyptal is progressing, aiming to expand its use outdoors without degradation.

- Bio-based Resins: Innovations include creating more sustainable, bio-based resins that could reduce environmental impact and improve biodegradability.

Technological Advancements in Dacron Production

The future of Dacron looks promising with ongoing technological advancements:

- Improved Recycling Techniques: Enhanced recycling methods are being developed to make Dacron production more sustainable.

- High-Performance Fibers: Research into higher-performance Dacron fibers aims to enhance their utility in high-stress environments like aerospace and automotive industries.

Frequently Asked Questions

What is Glyptal Used For?

Glyptal is extensively used as an insulating varnish in electrical applications, particularly for coating electric motor coils and transformer cores. Its excellent adhesion properties and electrical insulation capabilities make it ideal for protecting electrical components from moisture and mechanical damage.

How is Dacron Manufactured?

Dacron is produced through a process called polymerization, where ethylene glycol and terephthalic acid are combined to form the polyester known as polyethylene terephthalate (PET). This material is then melted and extruded through a spinneret to create fibers that are drawn, stretched, and treated to produce the final Dacron fabric.

What Are the Environmental Impacts of Using Dacron?

Dacron, being a synthetic polyester, poses certain environmental challenges, primarily due to its non-biodegradable nature. However, advances in recycling technologies have made it possible to repurpose used Dacron into new textiles, thereby reducing its ecological footprint and encouraging sustainable practices in the industry.

Can Glyptal Be Used in Outdoor Applications?

While Glyptal is highly effective in indoor electrical applications, its use in outdoor environments is limited due to its susceptibility to degradation under UV exposure and extreme weather conditions. Protective coatings and UV inhibitors can enhance its outdoor performance, albeit with some limitations.

Conclusion

The choice between Glyptal and Dacron ultimately depends on the specific requirements of the application at hand. Glyptal excels in environments requiring robust electrical insulation, while Dacron is unmatched in applications demanding strength and durability in fabrics. Both materials showcase the remarkable versatility and adaptability of synthetic polymers in modern engineering and design.

As industries continue to evolve and new technologies emerge, the roles of Glyptal and Dacron are likely to expand and diversify. Continued research and development will further enhance their properties and applications, solidifying their status as indispensable materials in their respective fields. Understanding their unique characteristics enables manufacturers and consumers to make informed decisions, optimizing the performance and sustainability of their products.