Gelatinization and gelation are two fundamental processes widely utilized in various industrial applications, notably in food and pharmaceutical manufacturing. Both involve the interaction of polymers and liquids but serve different functions and result from different conditions. These processes are pivotal for altering the physical properties of substances to achieve desired textures and consistencies.

Gelatinization occurs when starch granules absorb water upon heating, causing them to swell and eventually burst, leading to a viscous paste or gel. This transformation is critical in cooking and baking, affecting the texture and appearance of the final product. Gelation, on the other hand, refers to the formation of a gel from proteins or polymers, where the structure becomes firm and elastic after cooling or setting, which is essential in products like jellies and gels.

The difference between gelatinization and gelation lies in their respective mechanisms and outcomes. Gelatinization is a reversible physical change primarily involving starch, while gelation is often irreversible, forming a network-like structure that can hold solids and liquids in a stable matrix. Understanding these differences is crucial for optimizing product formulations in food science, material engineering, and therapeutic development.

Defining Gelatinization

What is Gelatinization?

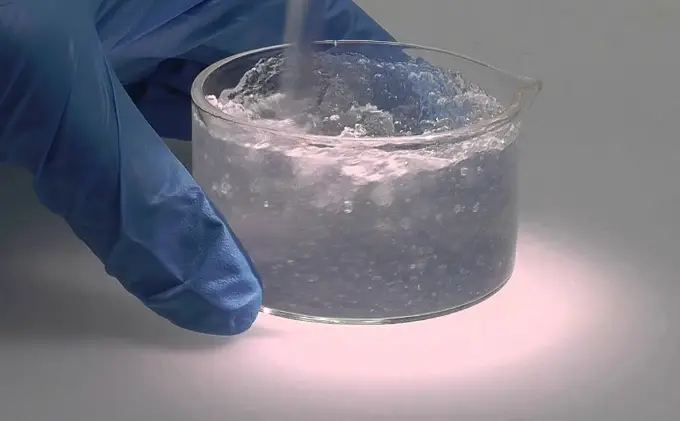

Gelatinization is a thermally activated process where starch granules absorb water and swell upon heating. This process is crucial in various culinary and industrial applications, as it transforms the physical properties of starch into a paste or gel, affecting the texture and functionality of the product.

Key Characteristics

The key characteristics of gelatinization include:

- Swelling: Starch granules absorb water and increase in volume.

- Loss of Crystallinity: The ordered structure of starch breaks down.

- Viscosity Increase: The mixture becomes thicker as granules rupture.

- Translucence: The gel becomes less opaque as starch granules swell.

The Process Explained

Gelatinization involves several steps:

- Water Absorption: Starch granules begin to absorb water when mixed and heated.

- Swelling: As the temperature rises, the granules swell and soften.

- Rupture: At peak temperature, the granules burst, releasing the molecular contents.

- Gel Formation: A thick, viscous gel forms as the mixture cools.

Defining Gelation

What is Gelation?

Gelation refers to the process where polymers, such as proteins or polysaccharides, form a gel. This occurs when fluid colloidal dispersions solidify into a semi-solid state, creating a network that traps water molecules. This process is fundamental in manufacturing products like gels, jellies, and structured foods.

Distinct Features

The distinct features of gelation include:

- Network Formation: Formation of a three-dimensional network that immobilizes liquid.

- Irreversibility: Often irreversible as it involves chemical bonds or strong physical interactions.

- Elasticity: The gel exhibits elastic properties, being firm yet deformable.

Overview of the Process

Gelation typically involves:

- Heating: Polymers are dissolved in a solvent and heated.

- Cooling or Setting: Upon cooling or adding specific reactants, polymers link together.

- Network Creation: A network forms that traps solvent inside, leading to gel formation.

Gelatinization Process

Stages of Gelatinization

The stages of gelatinization are:

- Initial Absorption: Starch and water mix, and heating begins.

- Granular Swelling: The granules swell as they absorb more water.

- Loss of Order: The crystalline regions within granules lose their structured order.

- Viscosity Peak and Rupture: The mixture reaches maximum viscosity; granules rupture.

- Cooling and Gel Setting: As the mixture cools, a gel forms.

Factors Influencing Gelatinization

Several factors influence gelatinization:

- Starch Type: Different starches (corn, potato, rice) gelatinize at different temperatures.

- Water Ratio: More water leads to better swelling and gel formation.

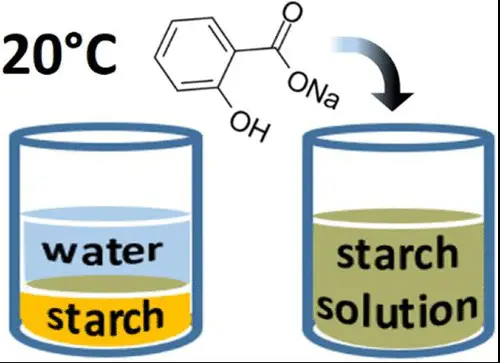

- pH Level: Acidic or alkaline environments can affect the integrity of starch granules.

- Additives: Sugars and salts can alter the temperature and rate of gelatinization.

Role of Temperature and Water

Temperature and water play a critical role in gelatinization:

- Temperature: Higher temperatures speed up the swelling and rupture of starch granules.

- Water: Sufficient water is necessary for the granules to absorb and swell effectively.

Gelation Process

Stages of Gelation

The stages of gelation are:

- Polymer Dissolution: Polymers dissolve in a liquid medium upon heating.

- Cooling and Linking: As the solution cools, polymers begin to connect, forming a network.

- Solidification: The network traps water, and the gel solidifies.

Influencing Factors

Factors that influence gelation include:

- Polymer Concentration: Higher concentrations lead to stronger gels.

- Temperature: Lower temperatures usually promote faster gelation.

- Chemical Reactants: Certain chemicals can catalyze or inhibit gel formation.

Temperature and Time Dependency

Both temperature and time are crucial for gelation:

- Temperature Control: Precise temperature control is needed to balance the rate of gelation and the properties of the final gel.

- Time Management: The duration of heating and cooling affects the structure and firmness of the gel.

Comparative Analysis

Similarities between Gelatinization and Gelation

Both gelatinization and gelation are crucial in transforming the physical properties of substances in various industries, primarily food and pharmaceuticals. Key similarities include:

- Phase Transition: Both processes involve a phase transition from a solid or semi-solid state to a more fluid gel state.

- Water Interaction: Water plays a critical role in both processes, whether it’s being absorbed during gelatinization or helping to form a network during gelation.

- Temperature Dependence: Both processes are highly temperature-dependent, requiring specific thermal conditions to initiate and complete.

- Impact on Product Texture: Each process significantly alters the texture and consistency of the final product, making them essential in texture engineering.

Key Differences Highlighted

While gelatinization and gelation share some fundamental aspects, their differences are distinct:

- Material Involvement: Gelatinization primarily involves starch, whereas gelation can involve a variety of polymers, including proteins and synthetic polymers.

- Mechanism: Gelatinization is a swelling and bursting of starch granules, while gelation is the formation of a network through physical or chemical links.

- Reversibility: Gelatinization can sometimes be reversed by removing water and drying, but gelation often results in irreversible structures.

Applications in Industry

Gelatinization in Food Production

Gelatinization has a profound impact on food production:

- Baking: Enhances the structure and moisture content in baked goods like bread and cakes.

- Sauces and Gravies: Provides the thickening necessary for the desired consistency.

- Pasta and Noodles: Allows for the proper texture and cooking properties essential in these products.

Gelation in Pharmaceuticals

In the pharmaceutical industry, gelation is utilized for its unique properties:

- Drug Delivery Systems: Gels formed through gelation can encapsulate drugs, providing controlled release mechanisms.

- Topical Applications: Gels are used for creams and ointments, offering a suitable medium for skin application.

Other Industrial Applications

Both processes find applications across various industries:

- Textiles: Gelation is used in the finishing of textiles to provide certain textures and finishes.

- Biotechnology: Gelatinization is used in the production of biodegradable materials and packaging.

Practical Implications

Impact on Product Quality

The control and understanding of gelatinization and gelation are essential for ensuring high-quality products:

- Consistency and Stability: Proper use of these processes ensures that foods and pharmaceuticals maintain consistency and stability under varying conditions.

- Texture and Sensory Properties: The texture, appearance, and mouthfeel of food products can be finely tuned to meet consumer expectations.

Examples from Real-World Applications

Real-world applications of gelatinization and gelation demonstrate their broad utility:

- Food Industry: Instant noodles rely heavily on gelatinization for quick cooking times and desirable texture. Jellies and puddings depend on gelation for their firm yet pliable consistency.

- Pharmaceuticals: Hydrogel patches for drug delivery illustrate how gelation can be manipulated to create products that release medicinal compounds over an extended period.

- Cosmetics: Gels in beauty products, often created through gelation, provide a smooth application and extended wear on the skin.

FAQs

What triggers gelatinization?

Gelatinization is triggered by the combination of water and heat. As starch is heated in water, the granules absorb water, swell, and eventually burst, transforming their crystalline structure into a less ordered state, resulting in a thick, viscous paste.

How does gelation occur?

Gelation occurs when certain substances, typically proteins or polysaccharides, are cooled after being heated or when specific chemicals are added. This process results in the formation of a gel-like network that can trap water, creating a firm, structured product.

Are gelatinization and gelation reversible?

Gelatinization can be somewhat reversible, allowing some starches to return to a granular state upon cooling and drying. However, gelation is typically irreversible as it involves the formation of chemical bonds or strong physical interactions that are not easily undone.

Where are these processes used?

Both gelatinization and gelation are crucial in the food industry for products like bread, cakes, puddings, and jellies. Additionally, gelation plays a significant role in pharmaceuticals for creating sustained-release drug formulations.

Conclusion

The processes of gelatinization and gelation are integral to the design and manufacture of a wide range of products across different industries. By understanding the distinct mechanisms and effects of each process, professionals can better tailor the texture, stability, and functionality of products. This knowledge not only enhances product quality but also promotes innovation in developing new applications and improving existing ones.

In summary, the intricate details of gelatinization and gelation not only highlight their importance in industrial applications but also underline the complex nature of material science. As industries strive to meet specific consumer needs, the mastery of these processes becomes a pivotal element in the advancement of food technology and pharmaceutical formulations.