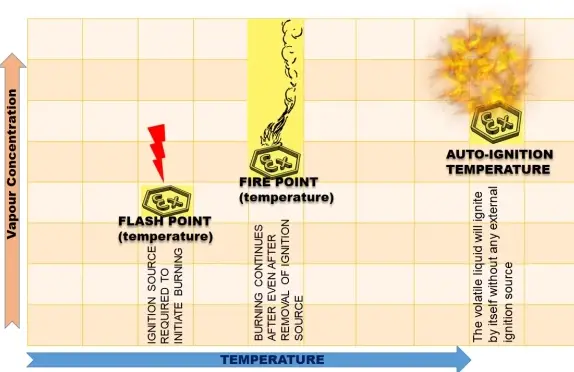

Flash point and auto ignition temperature are critical terms in the fields of chemistry and safety engineering, pivotal for understanding fire hazards associated with various substances. These concepts are fundamental in determining how substances interact with sources of ignition and at what temperatures they might ignite. Each parameter offers distinct insights into the preventive measures necessary for handling flammable materials safely.

The flash point of a substance is the lowest temperature at which its vapors ignite if given an ignition source. Auto ignition temperature, on the other hand, is the temperature at which a material spontaneously ignites without any external ignition source. Understanding these temperatures is crucial for managing fire risks and ensuring safe material handling in numerous industrial settings.

The accurate measurement and comprehension of these temperatures help in designing safer industrial processes, storing materials properly, and preventing fire accidents. They serve as benchmarks in regulations and safety standards globally, affecting industries ranging from petrochemicals to automotive manufacturing.

Flash Point Explained

Definition and Overview

The flash point of a substance is the lowest temperature at which it can vaporize to form an ignitable mixture in air. This critical property is used to classify the flammability and combustibility of liquids. A lower flash point means that the liquid can ignite at a lower temperature, posing a greater fire risk.

Factors Influencing Flash Point

Several factors can affect the flash point of a substance:

- Chemical Composition: The inherent chemical structure of a liquid determines how readily it emits vapors that can ignite.

- Pressure: Increases in ambient pressure can raise the flash point.

- Impurities: Even small amounts of highly volatile impurities can significantly lower a liquid’s flash point.

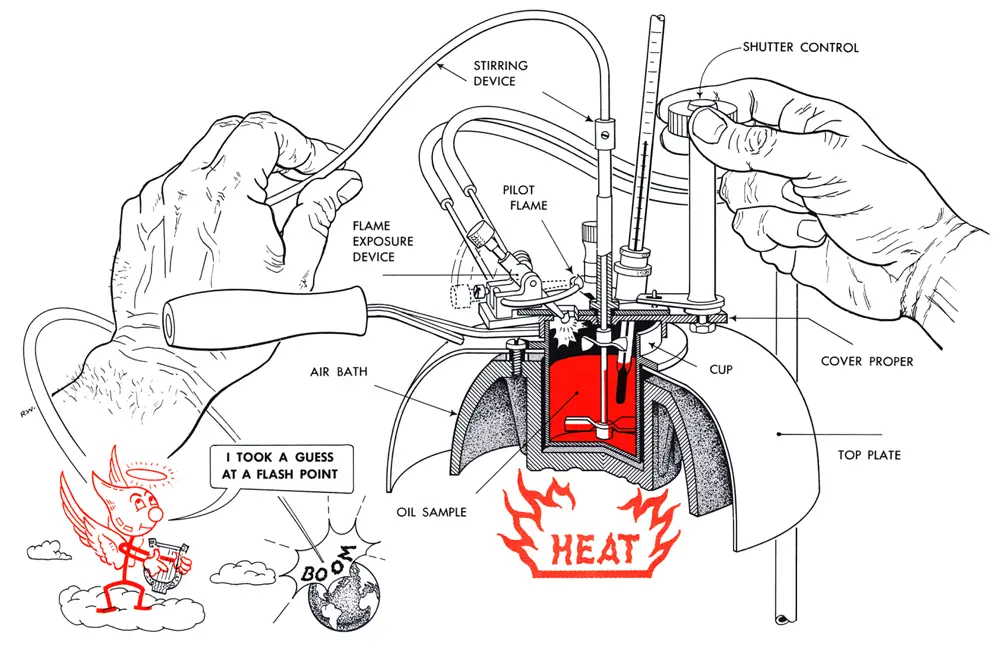

Common Testing Methods

Testing for flash point is performed using two primary methods:

- Open Cup Method: The liquid is placed in an open vessel and heated while an ignition source is passed over the top, until vapors ignite.

- Closed Cup Method: Similar to the open cup, but done in a sealed vessel, providing more controlled and lower flash points.

These methods help determine safe handling and storage practices for flammable liquids.

Auto Ignition Temperature Explained

Definition and Significance

Auto ignition temperature is the temperature at which a material spontaneously ignites without any external ignition source, such as a flame or spark. This temperature is a vital characteristic for assessing the fire hazard of materials, especially in environments where high temperatures can be reached during processes.

Factors Affecting Auto Ignition

The auto ignition temperature of a material can be influenced by:

- Composition: Materials made of more combustible compounds have lower auto ignition temperatures.

- Environmental Conditions: Oxygen concentration and pressure in the environment can alter the auto ignition temperature.

- Physical Form: Finer materials, like powders or dusts, have lower auto ignition temperatures due to their high surface area to volume ratio.

Standard Measurement Techniques

To determine auto ignition temperature, the following standardized methods are commonly used:

- ASTM E659: A method involving heating a small sample in a temperature-controlled oven until it ignites.

- ISO 871: Used for plastics, providing a standard approach to assess their auto ignition temperatures under controlled conditions.

Comparative Analysis

Key Differences Summarized

- Ignition Source: Flash point requires an external source; auto ignition does not.

- Temperature Range: Flash points are generally lower than auto ignition temperatures.

- Application: Flash point is crucial for transport and storage; auto ignition is critical for process safety.

Table Comparison: Flash Point vs. Auto Ignition Temperature

| Property | Flash Point | Auto Ignition Temperature |

|---|---|---|

| Definition | Lowest temperature at which vapors ignite from an external source | Temperature at which material ignites without external source |

| Measurement | Open and Closed Cup methods | ASTM E659, ISO 871 |

| Importance | Essential for safe storage and handling | Key for assessing environmental and process-related fire risks |

Impact on Material Safety

Role in Hazardous Material Handling

Understanding the flash point and auto ignition temperature is crucial for developing safety protocols in industries handling hazardous materials. This knowledge dictates how substances are stored, what kind of fire suppression systems are needed, and the types of containers used for transport.

Examples from Industry

- Petroleum Industry: Petroleum products have varying flash points and auto ignition temperatures, influencing everything from refinery safety measures to the design of storage tanks.

- Chemical Manufacturing: In chemical manufacturing, knowing these temperatures ensures that processes are operated within safe limits to prevent accidental ignitions.

Regulatory Standards

Overview of Global Safety Standards

Global safety standards are crucial for ensuring consistent practices in the handling, storage, and transportation of flammable substances. These standards aim to minimize the risk of fire hazards and enhance safety in various industries. They encompass a range of directives, codes, and guidelines developed by international organizations and regulatory bodies to address the complexities of industrial safety.

Specific Regulations (OSHA, NFPA)

OSHA (Occupational Safety and Health Administration) and NFPA (National Fire Protection Association) are two key bodies that set forth regulations impacting how materials are handled in the workplace, particularly concerning their flash point and auto ignition temperatures.

- OSHA Regulations: OSHA’s guidelines focus on providing a safe working environment. They mandate specific practices for handling chemicals with low flash points and high auto ignition temperatures to prevent workplace injuries and accidents.

- NFPA Codes: NFPA provides codes (e.g., NFPA 30: Flammable and Combustible Liquids Code) that outline the necessary precautions and setups for storing and handling flammable substances. These codes are widely adopted to ensure safety across industries.

Industry Applications

Automotive Industry Use-Cases

In the automotive industry, understanding the flash point and auto ignition temperature is vital for the design and safety of fuel systems and storage solutions. For example, the selection of materials used in fuel lines, the design of the fuel tank, and the specifications for fuel transport are all influenced by these properties.

- Fuel Safety: Ensuring that all materials used in the fuel system meet the required safety standards regarding their flash point and auto ignition temperatures prevents potential fire hazards.

- Battery Safety: In electric vehicles, battery safety is paramount. Manufacturers study the auto ignition temperatures of battery components to prevent thermal runaway and ensure safe operating conditions.

Chemical Engineering and Safety

Chemical engineers must design processes that safely handle substances prone to ignition. Knowledge of flash point and auto ignition temperature informs the development of:

- Safety Measures: Implementation of safety protocols that prevent the approach of temperatures near a substance’s auto ignition point.

- Process Design: Designing chemical processes that operate safely at temperatures well below the critical ignition temperatures of the used chemicals.

Preventive Measures

Best Practices for Handling Materials

To safely handle materials with specific flash points and auto ignition temperatures, industries adopt best practices that include:

- Proper Labeling: Ensuring all materials are correctly labeled with their flash point and auto ignition temperature information.

- Safety Training: Conducting regular safety training for employees to handle flammable substances safely.

- Temperature Control: Implementing strict controls on process temperatures and storage conditions.

Case Studies and Historical Accidents

Studying past accidents provides valuable insights into the importance of adhering to safety standards concerning flash points and auto ignition temperatures. For example:

- The Bhopal Disaster (1984): Improper storage and handling of chemicals with low auto ignition temperatures led to one of the worst industrial disasters in history.

- The Texas City Refinery Explosion (2005): This incident highlighted the critical need for maintaining substances below their flash points during storage and processing.

Frequently Asked Questions

What is Flash Point?

Flash point refers to the minimum temperature at which a liquid generates enough vapor to ignite in the presence of an ignition source. This property is essential for assessing the flammability of liquids and ensuring the safety of their transport and storage.

How is Auto Ignition Temperature Measured?

Auto ignition temperature is typically measured in a controlled laboratory setting using a standardized apparatus. The substance is heated in an environment free from flames or sparks, and the temperature at which it ignites is recorded as the auto ignition temperature.

Why Are These Temperatures Important?

Understanding flash point and auto ignition temperature is crucial for safety management in environments that handle combustible materials. They help determine necessary safety protocols, such as proper storage conditions, handling procedures, and emergency response tactics.

Can Flash Point and Auto Ignition Temperature Be the Same?

While both temperatures relate to a substance’s ignition, they are rarely the same. Flash point occurs at a lower temperature, where minimal vapor is produced, while auto ignition requires a higher temperature for spontaneous ignition without an external source.

Conclusion

In conclusion, the concepts of flash point and auto ignition temperature are integral to industrial safety and chemical engineering. They not only dictate the handling and storage requirements of volatile substances but also underpin many of the safety regulations in place today. By understanding these properties, industries can better protect workers and the public from potential hazards associated with combustible materials.

In a world that relies heavily on the use of chemicals and flammable materials, such knowledge is not just technicality—it is a necessity. Ensuring that this information is well understood and implemented can significantly reduce the risk of fire incidents, promoting a safer industrial environment.