Ethanol and dimethyl ether are two chemical compounds that often feature prominently in discussions about sustainable fuels and industrial solvents. Both substances play crucial roles in various sectors, from automotive to pharmaceuticals, offering distinct benefits and challenges. Each compound’s unique properties and applications make it essential for specific purposes, affecting everything from environmental impact to economic viability.

Ethanol, commonly known as alcohol, is primarily used as a biofuel and solvent, produced through the fermentation of sugars found in agricultural crops. In contrast, dimethyl ether is a clean-burning diesel alternative with applications ranging from aerosol propellants to refrigeration. It is usually produced via the dehydration of methanol, which itself is derived from natural gas.

While both ethanol and dimethyl ether serve as alternatives to traditional fossil fuels, their differences in chemical structure, production methods, and applications highlight the diversity of options available for reducing environmental impact and enhancing fuel security. The choice between these compounds depends on various factors including source availability, desired chemical properties, and the specific application’s environmental regulations.

Basic Properties

Ethanol: Chemical Structure and Sources

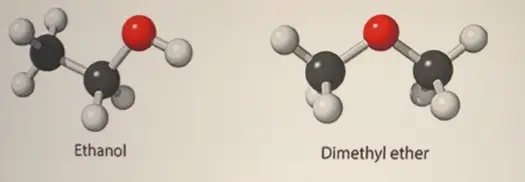

Ethanol, often referred to simply as alcohol, has the chemical formula C2H5OH. It is a volatile, flammable liquid that forms an essential part of alcoholic beverages and is widely used in industrial applications. Structurally, ethanol consists of a hydroxyl group attached to a two-carbon chain, making it the simplest alcohol.

The primary sources of ethanol are agricultural products that contain substantial amounts of sugars or starches. These include:

- Corn: The most common source in the United States, where cornstarch is fermented into ethanol.

- Sugarcane: Used extensively in Brazil, sugarcane ferments directly into ethanol.

- Wheat and barley: Often used in Canada and Europe.

These sources are fermented using yeast, which converts the sugars into ethanol and carbon dioxide, a process that not only produces fuel but also plays a crucial role in the beverage industry.

Dimethyl Ether: Chemical Structure and Sources

Dimethyl ether (DME) is an organic compound with the formula CH3OCH3. It is a colorless gas that is used as an aerosol propellant and a refrigerant. DME is unique because it can be produced from a variety of sources, including:

- Natural gas: Through the dehydration of methanol, which is derived from natural gas.

- Biomass: Using black liquor and other waste products from the wood industry.

- Coal: By gasification, followed by methanol synthesis and dehydration.

DME’s versatility in production from both fossil and renewable sources makes it an attractive alternative fuel.

Production Methods

Ethanol Production Techniques

The production of ethanol involves several key steps:

- Preparation of the feedstock:

- Corn: The corn is milled to break down the starch.

- Sugarcane: The cane is crushed to extract the juice.

- Fermentation:

- Yeast is added to the prepared feedstock. It ferments the sugars present into ethanol and carbon dioxide.

- Distillation:

- The mixture is heated, and since ethanol has a lower boiling point than water, it vaporizes first. The vapors are condensed back into liquid form.

These steps ensure that ethanol is produced efficiently and is ready for use as a biofuel or in other industrial applications.

Dimethyl Ether Production Techniques

Producing DME typically involves the following steps:

- Methanol Production:

- From natural gas or coal, methanol is produced through a process of gasification and synthesis.

- Dehydration:

- The methanol undergoes dehydration, a chemical reaction that removes water molecules, forming DME.

This process allows for the production of DME on a large scale, suitable for its various applications.

Physical Characteristics

Boiling Points and Solubility

- Ethanol has a boiling point of about 78°C. It is completely soluble in water, making it an excellent solvent for organic compounds.

- Dimethyl ether has a much lower boiling point of -24°C and is sparingly soluble in water. However, it dissolves well in organic solvents.

Density and Viscosity Comparisons

- Ethanol is denser than water, with a density of about 0.789 g/cm³ at 20°C. It also has a higher viscosity than water, which is why it feels slightly thicker.

- Dimethyl ether, being a gas at room temperature, has a very low density and viscosity. This makes it ideal for use as an aerosol propellant.

Applications

Ethanol Uses in Industry

Ethanol is versatile in its applications, including:

- Fuel: Blended with gasoline to produce E10 or E85, reducing carbon emissions.

- Solvent: Used in the manufacture of varnishes and perfumes.

- Disinfectant: Ethanol kills bacteria and viruses effectively, making it a key ingredient in hand sanitizers.

Dimethyl Ether Uses in Industry

Dimethyl ether is used widely due to its properties as a clean-burning diesel alternative and its applications include:

- Propellant: In aerosol products due to its low toxicity and good solvency.

- Fuel: As a liquefied gas, it’s used in diesel engines for trucks and buses, providing a soot-free combustion.

- Refrigerant: In air-conditioners and refrigerators, offering an environmentally friendly alternative to traditional refrigerants.

Environmental Impact

Emissions During Production

Ethanol production primarily involves fermentation, a biological process that emits carbon dioxide (CO2). However, these emissions are often considered neutral in the carbon cycle, as the plants used to produce ethanol (like corn and sugarcane) absorb CO2 as they grow. Nevertheless, indirect emissions come from the use of fossil fuels in the cultivation, harvesting, and transportation of these crops.

Dimethyl ether (DME) production, particularly from natural gas, involves steps like gasification and methanol synthesis, which can emit various pollutants including CO2, nitrogen oxides (NOx), and sulfur oxides (SOx). When produced from biomass or coal, the emissions vary based on the feedstock and the technology used.

Effects on Air Quality

Both ethanol and DME influence air quality differently when burned as fuels:

- Ethanol: When blended with gasoline, ethanol can help reduce emissions of tailpipe pollutants like particulate matter (PM) and NOx. However, higher ethanol blends can increase emissions of acetaldehyde, a volatile organic compound.

- Dimethyl ether: As a diesel fuel alternative, DME combustion produces virtually no particulate matter and significantly lower NOx levels, which are beneficial for urban air quality.

Economic Aspects

Cost of Production

The cost of producing ethanol is heavily influenced by the prices of raw materials, especially corn and sugarcane, and the energy required for distillation and dehydration processes. Advances in technology and increased production scale can reduce these costs over time.

Dimethyl ether’s production cost largely depends on the cost of methanol and the infrastructure for DME synthesis. As methanol can be derived from various sources, including natural gas and renewables, the economic feasibility of DME can be highly variable.

Market Trends and Predictions

The ethanol market is mature, especially in countries with strong biofuel mandates such as the USA and Brazil. Future growth is expected to come from countries adopting new biofuel policies and from technological advancements that lower production costs or increase yields.

The market for dimethyl ether is growing, particularly in regions like Asia where it is used as a clean alternative to diesel and as a household fuel. Its adoption is also expected to increase globally as countries seek cleaner combustion technologies to meet air quality standards.

Safety and Handling

Storage Requirements

Ethanol must be stored in specially designed tanks to prevent contamination and support its hygroscopic nature, which can lead to water absorption and fuel dilution.

Dimethyl ether requires pressurized storage tanks similar to those used for liquefied petroleum gas (LPG), as it remains a gas at room temperature but can be liquefied under moderate pressure.

Transportation Regulations

Transporting both ethanol and DME involves strict regulations:

- Ethanol is classified as a flammable liquid, necessitating specific safety measures during transport, including placarding and adherence to road and rail safety regulations.

- Dimethyl ether is classified as a compressed gas, which imposes requirements for pressure vessels and hazard communications for safe handling.

Technological Advances

Innovations in Ethanol Production

Recent innovations in ethanol production focus on improving the efficiency and sustainability of the fermentation and distillation processes. These include:

- Genetic engineering of yeast strains that can ferment sugars more efficiently.

- Development of cellulose-based ethanol, which uses non-food plant materials, reducing the dependency on edible crops.

Breakthroughs in Dimethyl Ether Applications

Technological breakthroughs in DME applications are making it more attractive for a variety of uses:

- Development of DME-dedicated combustion systems that can handle its properties and maximize its environmental benefits.

- Advances in catalyst technologies that improve the efficiency of DME production from methanol, lowering overall production costs.

Frequently Asked Questions

What is Ethanol?

Ethanol, also known as ethyl alcohol, is an organic chemical compound, often used as a renewable fuel additive and solvent. It is produced through the fermentation of sugars by yeast, primarily derived from crop sources like corn and sugarcane.

How is Dimethyl Ether Produced?

Dimethyl Ether (DME) is produced from methanol through a process called dehydration. Methanol itself is obtained from natural gas or biomass, making DME a potentially greener alternative to traditional fossil fuels.

Are Ethanol and Dimethyl Ether Environmentally Friendly?

Both ethanol and dimethyl ether are considered more environmentally friendly compared to conventional fuels. Ethanol can reduce greenhouse gas emissions, while dimethyl ether produces no soot when burned, significantly lowering air pollution.

Can Ethanol Be Used in All Engines?

Ethanol can be used in most modern engines, but typically it is blended with gasoline to create E10 or E85 fuels. Higher concentrations of ethanol may require specific engine modifications to avoid damage.

What Are the Main Uses of Dimethyl Ether?

Dimethyl ether is primarily used as an aerosol propellant and as a refrigerant. Its application as a clean diesel alternative is also growing, thanks to its ability to produce minimal soot during combustion.

Conclusion

Ethanol and dimethyl ether represent two facets of the ongoing quest to develop more sustainable chemical solutions for energy and industrial applications. While both offer benefits that can significantly reduce environmental impact, they cater to different needs and industries based on their chemical properties and production methods. Decisions on their adoption and use must consider these factors to optimize benefits while minimizing drawbacks.

As industries continue to evolve and environmental regulations become stricter, both ethanol and dimethyl ether are poised to play pivotal roles. Their continued development and integration into various sectors are crucial for achieving more sustainable and environmentally friendly solutions across the globe.