Polymers and elastomers are foundational materials that play pivotal roles in various industries, from automotive to healthcare, shaping the functionality and innovation of countless products. Polymers, large molecules composed of repeated subunits, serve as the backbone of plastics, fabrics, and even biological compounds. Elastomers, a specialized class of polymers, stand out for their rubber-like elasticity, allowing them to return to their original shape after being stretched or deformed. This unique property opens a wide range of applications that benefit from flexibility and resilience.

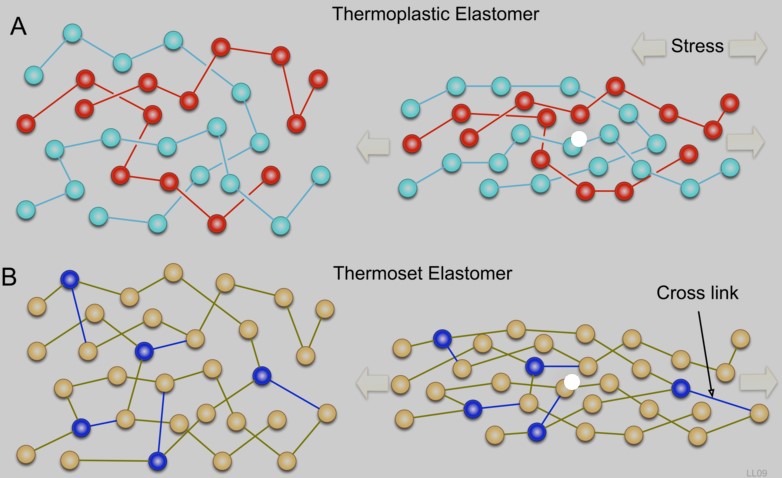

The difference between elastomers and polymers lies primarily in their chemical structure and physical properties. Polymers encompass a broad category of materials with diverse characteristics, including plastics, resins, and elastomers. Elastomers, however, are distinguished by their ability to undergo significant elastic deformation. This key distinction underpins the varied applications and functionalities of each material, with elastomers often being used where flexibility and durability are paramount.

Understanding the distinction between these materials is essential for material scientists, engineers, and product designers. It influences decisions in material selection, product design, and application, ensuring the optimal use of each material’s properties. The interplay between structure and function in polymers and elastomers highlights the importance of material science in advancing technology and innovation.

Polymers Explained

Definition and Characteristics

Polymers are large molecules composed of many repeated subunits, known as monomers. These materials are fundamental to a wide array of applications due to their versatile properties. Characteristics of polymers include durability, flexibility, and resistance to chemicals and environmental factors. The unique aspect of polymers is their ability to exhibit a range of physical properties, which can be adjusted by altering their chemical composition or structure.

Types of Polymers

Polymers can be classified into several types based on their source or synthesis method:

- Natural Polymers: These occur in nature and include cellulose, proteins, and DNA. They are essential for life and offer incredible diversity in function.

- Synthetic Polymers: Manufactured in laboratories and factories, synthetic polymers include plastics like polyethylene, polystyrene, and polyvinyl chloride (PVC). These polymers are designed for specific applications, offering a broad range of properties.

- Biopolymers: A subset of natural polymers, biopolymers are produced by living organisms. Examples include silk, wool, and natural rubber. They are gaining popularity due to their sustainability and biodegradability.

Common Uses and Examples

Polymers are everywhere in our daily lives, with their applications spanning across industries:

- Packaging: Polymers like polyethylene and PVC are widely used in packaging for their durability and flexibility.

- Construction: Polystyrene and polyurethane are used in insulation, piping, and flooring due to their strength and thermal properties.

- Electronics: Polymers are key in the manufacturing of components for computers, phones, and other devices, thanks to their electrical insulation properties.

Elastomers Unpacked

Definition and Properties

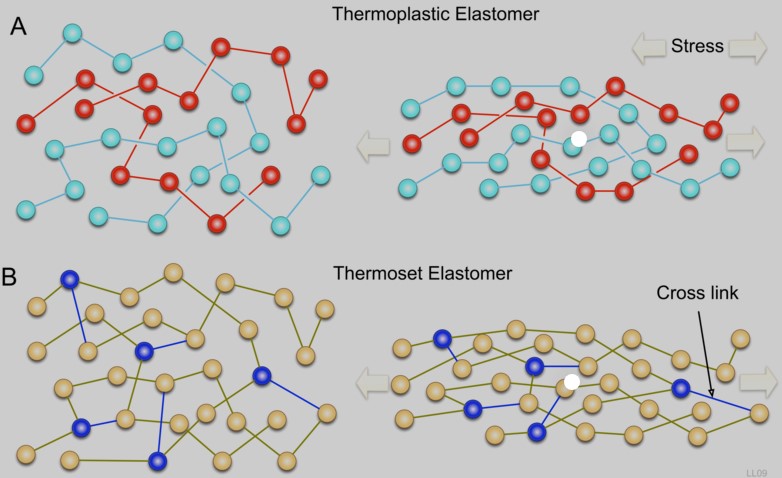

Elastomers are a special class of polymers known for their elasticity. They can stretch significantly and return to their original shape without permanent deformation. This elasticity comes from their molecular structure, which allows the polymer chains to move but return to their initial position due to cross-linking. Key properties of elastomers include high flexibility, resilience, and a broad operating temperature range.

How Elastomers Differ from Other Polymers

The primary difference between elastomers and other polymers is their elastic behavior. While all polymers have some degree of flexibility, elastomers can be stretched to multiple times their original length without breaking. This is due to the cross-links between the polymer chains, which provide the material with its unique elastic properties.

Applications and Examples

Elastomers are critical in various applications where flexibility and durability are essential:

- Automotive: Tires, seals, and gaskets made from elastomers ensure durability and performance under varying conditions.

- Medical Devices: Silicone elastomers are used in a range of medical devices, including tubing, implants, and prosthetics, for their biocompatibility and flexibility.

- Sporting Goods: Items like elastic bands, footwear, and protective gear utilize elastomers for comfort and impact resistance.

Key Differences

Chemical Structure

The chemical structure of polymers and elastomers is a fundamental difference. Polymers can have linear, branched, or networked structures, while elastomers typically have a cross-linked network. These cross-links are crucial for the elastic properties of elastomers, allowing the material to be stretched and return to its original shape.

Physical Properties

In terms of physical properties, elastomers stand out for their elasticity and ability to withstand significant deformation without breaking. Polymers, in general, may be rigid, flexible, or somewhere in between, depending on their molecular makeup and processing.

Thermal Behavior

The thermal behavior of elastomers and polymers also differs. Elastomers can maintain their elastic properties across a wide temperature range, making them ideal for applications exposed to varying environmental conditions. Polymers, depending on their type, may become brittle in cold temperatures or soften in heat.

Applications and Utility

The applications of polymers and elastomers are vast and varied. While polymers are used in everything from packaging to construction and electronics, elastomers are specifically chosen for applications requiring high flexibility and durability, such as in the automotive and medical industries. This distinction in applications highlights the importance of understanding the properties and capabilities of each material to ensure they are used to their fullest potential.

Elastomers in Industry

Elastomers, with their unique elastic properties, are integral to numerous industries. Their ability to stretch and revert to their original shape without damage is critical for applications demanding durability and flexibility.

Automotive Applications

In the automotive sector, elastomers are indispensable. They are used in a variety of components including:

- Tires: Elastomers provide the necessary resilience and durability, ensuring tires can absorb shocks and maintain grip.

- Seals and Gaskets: Essential for preventing leaks in engines and transmissions, elastomers withstand extreme temperatures and pressures.

- Hoses and Belts: Durability and flexibility make elastomers perfect for under-the-hood applications, where they must endure harsh conditions without failing.

These applications highlight elastomers’ contributions to vehicle safety, performance, and longevity.

Medical Uses

The medical field benefits significantly from elastomers due to their biocompatibility and flexibility. Examples include:

- Surgical Gloves: Made from latex or nitrile, these gloves protect both patients and healthcare workers.

- Implants and Catheters: Silicone elastomers are used for their flexibility and resistance to body fluids.

- Prosthetics: Elastomers provide the necessary comfort and adaptability for prosthetic limbs, improving quality of life for amputees.

Elastomers’ unique properties support advancements in medical technology and patient care.

Construction and Infrastructure

Elastomers play a pivotal role in construction and infrastructure, providing solutions that enhance durability and performance:

- Bridge Bearings: Absorb shocks and vibrations, ensuring structural integrity.

- Waterproofing Membranes: Protect buildings from water damage.

- Insulation Materials: Improve energy efficiency and reduce noise.

Their resilience and adaptability make elastomers critical in building and maintaining modern infrastructure.

Polymers in Daily Life

Polymers’ versatility and range of properties have made them ubiquitous in daily life. Their applications span from mundane household items to cutting-edge electronics.

Household Items

In our homes, polymers are everywhere:

- Kitchenware: Non-stick coatings and heat-resistant handles rely on polymers for functionality and safety.

- Furniture: Polymers provide durable finishes and structural components.

- Clothing: Synthetic fibers like polyester and nylon offer durability, flexibility, and ease of care.

The convenience and comfort of modern living are significantly enhanced by polymers.

Electronics and Gadgets

Electronics depend heavily on polymers for both functionality and aesthetics:

- Insulation and Wiring: Protects electrical components and ensures safety.

- Casings and Components: Polymers offer the right balance of strength, lightweight, and design flexibility.

- Displays: Polymers are used in screens for their optical properties and durability.

The ever-evolving tech landscape relies on polymers to push the boundaries of what’s possible.

Packaging Solutions

Packaging utilizes polymers extensively due to their versatility:

- Food Packaging: Keeps food fresh and protects it during transport.

- Protective Packaging: Cushions and protects items during shipping.

- Sustainable Packaging: Biodegradable polymers are increasingly used to reduce environmental impact.

Polymers in packaging combine functionality with sustainability, addressing consumer and environmental needs.

Environmental Impact

The environmental impact of polymers and elastomers is a growing concern, driving research into sustainable practices and materials.

Sustainability of Polymers

The sustainability of polymers is critical, with efforts focused on:

- Biodegradable Polymers: Designed to break down naturally, reducing landfill waste.

- Bio-based Polymers: Made from renewable resources, these polymers decrease reliance on fossil fuels.

These initiatives aim to make polymers more eco-friendly and sustainable.

Recycling and Reusability of Elastomers

Recycling elastomers poses challenges but offers significant environmental benefits:

- Mechanical Recycling: Involves breaking down elastomer products into granules for reuse.

- Chemical Recycling: Breaks down elastomers into their monomers, which can be polymerized again.

Innovations in elastomer recycling are crucial for reducing waste and conserving resources.

Future Trends in Polymer and Elastomer Production

Looking ahead, the production of polymers and elastomers will increasingly focus on:

- Sustainable Materials: Developing new polymers and elastomers that are eco-friendly and sustainable.

- Advanced Recycling Techniques: Enhancing the efficiency and scope of recycling processes.

- Innovative Applications: Expanding the use of polymers and elastomers in renewable energy, biomedicine, and beyond.

The future of these materials is intertwined with the pursuit of sustainability and innovation, promising new solutions to global challenges.

Frequently Asked Questions

What Are Polymers?

Polymers are large molecules made from many repeating units called monomers. These materials are ubiquitous in our daily lives, found in everything from plastic bottles and clothing to biological systems like DNA. Their vast array of properties, including strength, flexibility, and resistance to chemicals, make polymers incredibly versatile in both industrial and personal applications.

How Do Elastomers Work?

Elastomers work by stretching and returning to their original shape due to their molecular structure, which allows them to be highly elastic. This property is attributed to the polymer chains’ ability to extend and recoil, a feature that is critical in applications requiring flexibility and durability, such as tires, seals, and various rubber products.

Why Are Elastomers Unique Among Polymers?

Elastomers are unique among polymers due to their extraordinary elasticity. Unlike other polymers that might be brittle or rigid, elastomers can stretch significantly while maintaining their strength. This uniqueness comes from their cross-linked molecular structure, providing both flexibility and resilience under stress.

Can Polymers Be Recycled?

Yes, many polymers can be recycled, which involves reprocessing materials to reduce waste and environmental impact. However, the recyclability of polymers depends on their type, with some being easier to recycle than others. Advances in recycling technologies continue to improve the efficiency and feasibility of recycling various polymers, including some elastomers.

Conclusion

The exploration of elastomers and polymers reveals a fascinating intersection of chemistry, engineering, and technology that significantly impacts our daily lives and the environment. The distinction between these materials is not just academic but practical, guiding the innovation and application of flexible, durable, and sustainable solutions. As we continue to advance in material science, understanding the nuanced differences between elastomers and polymers becomes increasingly important in designing the next generation of products and technologies.

Recognizing the role of elastomers and polymers in modern society invites a deeper appreciation for the materials that shape our world. From the clothes we wear to the cars we drive, these materials offer a blend of versatility, functionality, and sustainability that will continue to drive human innovation forward. As we look to the future, the continued evolution and application of polymers and elastomers will undoubtedly play a key role in addressing the challenges and opportunities of the 21st century.