Polymers, in their myriad forms, are pivotal materials in modern engineering and design, bridging crucial gaps in industries ranging from automotive to healthcare. Elastomers and plastomers, two fundamental classes of polymers, exhibit distinct characteristics and functionalities which often lead to confusion about their applications and properties.

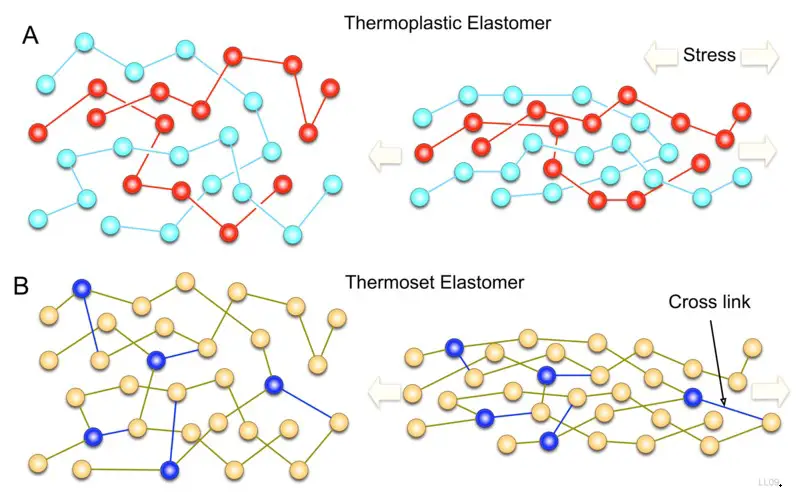

The primary difference between elastomers and plastomers lies in their molecular structure and physical properties. Elastomers are highly elastic materials, capable of significant stretching and returning to their original shape, while plastomers, though flexible, do not possess the same level of elasticity and are generally stiffer.

These materials not only differ in their physical abilities but also in their chemical composition. Elastomers are characterized by a cross-linked structure providing remarkable elasticity, whereas plastomers are linear or slightly branched, offering a balance between plasticity and flexibility. Understanding these distinctions is crucial for selecting the appropriate material for specific applications, influencing everything from everyday items to advanced industrial components.

Basic Definitions

Elastomers

What are Elastomers?

Elastomers are a type of polymer that can stretch significantly and return to their original shape without permanent deformation. They are often referred to as rubbers, both natural and synthetic, and are known for their extraordinary elasticity.

Key Properties

- High Elasticity: Elastomers can stretch up to 500-1000% of their original length.

- Flexibility: They remain flexible and malleable even at low temperatures.

- Durability: Resistant to abrasion and capable of enduring multiple stretching cycles without breaking.

Plastomers

What are Plastomers?

Plastomers are a class of polymers that share properties of both plastics and elastomers, offering moderate elasticity and better processability than conventional plastics. They are softer and more flexible than traditional plastics but less elastic than elastomers.

Key Properties

- Flexibility: While not as elastic, plastomers can flex without breaking.

- Moldability: They can be easily shaped into various forms through common plastic processing techniques.

- Lower Melting Point: Compared to traditional plastics, plastomers often have a lower melting point, which facilitates easier molding.

Chemical Structure

Elastomers

Polymer Chains and Cross-linking

The molecules in elastomers are long chains that are intertwined and connected by cross-links. These cross-links create a network that can be stretched and will always return to its original form.

Impact of Structure on Properties

- Elasticity: The cross-linked structure allows the material to stretch and recover.

- Strength: Cross-links provide strength and prevent the polymer from tearing under strain.

Plastomers

Polymer Chains and Configuration

Plastomer chains are typically linear or slightly branched, without extensive cross-linking, allowing for easier flow when melted and better processability.

Impact of Structure on Properties

- Flexibility: The linear or branched structure without tight cross-links makes plastomers flexible but less elastic.

- Processability: Easier to mold and shape due to their structural configuration which allows them to melt and flow.

Physical Properties

Elastomers

Flexibility and Elasticity

Elastomers are highly flexible and capable of significant extension. This is primarily due to their loosely tied, cross-linked polymer chains.

Temperature Resistance

- High Resistance: Elastomers can maintain their properties over a wide range of temperatures.

- Low Temperature Performance: Retain flexibility and elasticity even in cold environments.

Plastomers

Flexibility and Plasticity

Plastomers exhibit a high degree of flexibility, though not to the extent of elastomers. They can bend and adapt but will not stretch as much.

Temperature Performance

- Moderate Resistance: Plastomers handle moderate temperatures well but may become more rigid in cold or overly soft in heat.

- Versatility: Suitable for applications where variable temperature resistance is beneficial but extreme elasticity is not required.

Applications

Elastomers

Industrial and Commercial Uses

Elastomers are essential in fields requiring durable and stretchable materials. They are pivotal in the manufacturing of automotive tires, where their ability to absorb impacts and provide flexibility is critical. Additionally, they are used in the production of seals and gaskets that require airtight and watertight characteristics in machinery and appliances.

Examples in Daily Life

In everyday life, elastomers make up the soles of most sports shoes, offering both comfort and resilience. They are also used in medical devices like gloves and tubing, where non-reactive and flexible materials are crucial for patient safety and comfort.

Plastomers

Industrial and Commercial Uses

Plastomers blend the properties of plastics and elastomers, making them suitable for applications that demand a light but tough material. They are commonly used in the packaging industry, especially in the creation of cling films and food packaging that require a degree of stretchability and strength to maintain product integrity.

Examples in Daily Life

For everyday uses, plastomers are found in household storage bags and wraps, which are appreciated for their ability to seal food effectively and maintain freshness. They are also used in automotive interiors where flexibility combined with durability is essential.

Manufacturing Processes

Elastomers

Vulcanization

The process of vulcanization involves adding sulfur or other curatives to raw elastomers and heating them. This process creates cross-links between polymer chains, enhancing their elasticity and durability.

Molding Techniques

- Compression Molding: Here, the elastomer is shaped into a preheated mold cavity and then cured under pressure.

- Injection Molding: Elastomer is heated and injected into a mold, where it cures quickly, allowing for mass production of complex shapes.

Plastomers

Extrusion

Extrusion is a key process for forming plastomers. The plastomer material is melted and forced through a die to form long continuous shapes like tubes, films, or sheets, which are then cooled to solidify.

Injection Molding

Injection molding for plastomers involves melting the material and injecting it under pressure into a mold. This process is ideal for producing high-volume, intricate items with precise dimensions.

Environmental Impact

Elastomers

Biodegradability

Elastomers generally show low biodegradability, leading to longer persistence in the environment once disposed of.

Recycling Challenges

- Chemical Cross-linking: Makes elastomers difficult to recycle as they cannot be simply melted and reshaped.

- Material Contamination: Mixed elastomer types can complicate recycling processes.

Plastomers

Environmental Concerns

While plastomers are more versatile in recycling than elastomers, their widespread use, especially in single-use products, contributes significantly to plastic pollution.

Recycling Techniques

- Mechanical Recycling: Plastomers are often reprocessed into granules which can be remolded into new products.

- Chemical Recycling: Where material is broken down chemically back into monomers or other useful chemicals.

Market Trends

Demand Dynamics

The demand for both elastomers and plastomers continues to rise, driven by their versatile applications in emerging markets such as Asia-Pacific, where rapid industrialization and urbanization are ongoing.

Innovations in Material Science

Research is heavily focused on developing new formulations of both elastomers and plastomers that are more environmentally friendly, perform better, and are cheaper to produce. Innovations include bio-based materials and advancements in recycling technologies that could redefine the future landscape of polymer use.

Frequently Asked Questions

What are elastomers used for?

Elastomers are predominantly used in applications requiring flexibility and high elasticity. Common uses include tires, conveyor belts, and shock absorbers. Their ability to withstand repetitive stress makes them ideal for these dynamic applications.

What are plastomers used for?

Plastomers find their applications in products where a combination of flexibility, moldability, and lightness is necessary. These include food packaging films, plastic wraps, and automotive parts. Their adaptable nature makes them suitable for a wide range of manufacturing techniques.

How do elastomers differ from plastics?

While both elastomers and plastics are polymers, elastomers are known for their extreme elasticity, derived from their cross-linked molecular structure. Plastics, which include plastomers, may not exhibit such high levels of elasticity but offer greater rigidity and form stability.

Can elastomers and plastomers be recycled?

Elastomers pose significant challenges in recycling due to their cross-linked structure, which cannot be easily re-melted. Plastomers, on the other hand, are more amenable to recycling processes like melting and reshaping, depending on the specific type and purity.

Conclusion

Elastomers and plastomers play indispensable roles across various sectors due to their distinct physical and chemical properties. The ability of elastomers to revert to their original shape after stretching makes them ideal for dynamic environments, whereas plastomers serve well in static applications where flexibility and moldability are required. Recognizing these differences not only enhances material selection for specific applications but also pushes the boundaries of innovation in material science. As industries continue to evolve, the tailored use of these polymers will be critical in developing sustainable and efficient solutions.