The evolution of synthetic fibers has significantly shaped the fabric industry, offering materials that blend durability with versatility. Among these innovations, Dacron and Polyester stand out as prominent figures, each possessing unique characteristics that cater to various needs. Their development marked a turning point in textile manufacturing, providing alternatives to natural fibers with enhanced performance and utility.

Dacron and Polyester are both synthetic fibers, but they differ primarily in their applications and physical properties. Dacron, a trade name for a type of polyester, is often used in sails, thread, and batting due to its high tensile strength and resistance to stretching. Polyester, widely recognized for its versatility, is used in clothing, home furnishings, and industrial applications. Despite their similarities, the distinction lies in their specific utility and physical attributes, which cater to different demands in the textile industry.

The fabric industry’s leap towards synthetic fibers like Dacron and Polyester was driven by the pursuit of materials that could offer consistency, durability, and ease of maintenance. These fibers embody the modern textile industry’s goals, offering solutions that are not only practical but also adaptable to a wide range of applications. As we explore their differences and similarities, it’s clear that Dacron and Polyester have cemented their places as indispensable materials in both everyday items and specialized products.

Synthetic Fibers Overview

History

The journey of synthetic fibers begins in the late 19th and early 20th centuries, marking a pivotal era in the textile industry. The quest for materials that could mimic silk led to the first synthetic fiber, rayon, introduced in the 1890s. This was a groundbreaking development, providing an affordable alternative to luxury materials.

However, the true revolution came with the invention of nylon in the 1930s. Developed by Wallace Carothers and his team at DuPont, nylon was the first fiber made entirely from petrochemicals. This marked the dawn of the synthetic fiber age, as nylon’s success prompted further research and development in synthetic textiles.

Rise of Synthetic Fibers

The popularity of synthetic fibers soared after World War II. The demand for durable, lightweight, and easy-to-care-for fabrics led to the introduction of more synthetic materials, including polyester, acrylic, and spandex. These fibers offered unique properties such as resistance to wrinkles, stains, and moisture, reshaping fashion and home furnishings.

Types

Common Synthetic Fibers

- Polyester: Widely used due to its durability and resistance to shrinking and stretching.

- Nylon: Known for its strength and elasticity, ideal for stockings and sportswear.

- Acrylic: Often used as a wool substitute, acrylic is soft, warm, and lightweight.

- Spandex: Highly elastic, making it perfect for stretchable clothing.

Characteristics Overview

Synthetic fibers share some common characteristics, including strength, durability, and resistance to chemicals. They tend to be more affordable than natural fibers and offer greater versatility in their applications. However, their environmental impact is a growing concern due to non-biodegradability and reliance on fossil fuels for production.

What is Dacron?

Definition

Dacron is a trade name for a type of polyester fiber. It is recognized for its significant tensile strength and resistance to stretching, making it a popular choice in various applications.

Description and Origin

Developed in the 1950s by DuPont, Dacron was introduced as a part of the burgeoning family of synthetic fibers. Its invention aimed to offer a material that could provide higher strength and longer lifespan compared to existing fibers like rayon and nylon.

Properties

Physical Characteristics

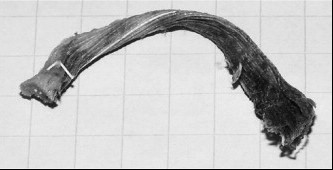

Dacron fibers are smooth, lightweight, and resistant to moisture. They have a high melting point, making them suitable for applications that require heat resistance.

Durability and Usage

Dacron’s durability makes it ideal for products that endure heavy wear and tear, such as sails, tents, and outdoor furniture. It’s also used in thread and batting for quilts due to its ability to retain shape and structure over time.

What is Polyester?

Definition

Polyester is a category of polymers made from ester groups in their main chain. As a textile, it’s one of the most widely used synthetic fibers in the world.

Description and Origin

Polyester’s history dates back to the early 20th century, but it became popular in the 1950s as a high-quality, affordable alternative to natural fibers. Its development was driven by the desire for more durable and maintenance-free materials.

Properties

Physical Characteristics

Polyester fibers are versatile, strong, and resistant to shrinking and wrinkling. They can be engineered to mimic natural fibers, offering a soft feel similar to cotton, wool, or silk.

Applications and Versatility

Polyester’s applications are broad and diverse. It is used in:

- Clothing: From everyday wear to high-performance sportswear.

- Home Furnishings: Including curtains, upholstery, and beddings.

- Industrial Uses: Such as car tire reinforcements, hoses, and ropes.

The ability to blend polyester with other fibers increases its utility, making it a staple in the textile industry for various products that demand durability, flexibility, and ease of maintenance.

Dacron vs Polyester

The textile industry often uses the terms Dacron and Polyester interchangeably, yet they hold distinct characteristics that set them apart. Understanding these differences is crucial for manufacturers, designers, and consumers alike, enabling informed decisions based on performance needs and application requirements.

Chemical Composition

Molecular Differences

At the molecular level, Dacron is a type of polyester, making it a subset within the broader polyester family. Polyester refers to a category of polymers made of ester functional groups in their main chain, while Dacron is a branded version of polyethylene terephthalate (PET), designed with specific performance characteristics in mind. This distinction is crucial for applications where the material’s chemical resistance, strength, and flexibility are paramount.

Physical Properties

Strength, Elasticity, and Moisture Absorption

- Strength: Dacron fibers are engineered for high tensile strength, making them ideal for applications requiring rigidity and durability. Polyester, in general, offers robust strength but with variations depending on the specific formulation.

- Elasticity: Polyester fabrics can be made with varying degrees of elasticity. Spandex, for instance, is a type of highly elastic polyester. Dacron, however, is designed to resist stretching, maintaining its shape over time.

- Moisture Absorption: Polyester has low moisture absorption, which contributes to its quick-drying properties. Dacron similarly repels water, making it suitable for outdoor and marine applications.

Durability and Maintenance

Lifespan and Care Instructions

Both Dacron and general polyester fabrics are celebrated for their longevity and ease of maintenance. They resist shrinkage, wrinkling, and most chemicals, making them easy to care for. Specific care instructions can vary, but most polyester and Dacron items can be machine washed and dried, although high temperatures should be avoided to prevent damage.

Environmental Impact

Production Process and Recyclability

The environmental footprint of synthetic fibers like Dacron and Polyester is significant, with their production relying heavily on fossil fuels. However, advances in recycling technologies have made it possible to recycle these materials, reducing the need for virgin resources and lowering the environmental impact. Dacron and Polyester can be broken down and transformed into new fibers or other products, promoting a circular economy in the textile sector.

Cost Comparison

Price Points and Affordability

One of the advantages of synthetic fibers like Dacron and Polyester is their affordability compared to natural fibers. The cost-effectiveness of polyester has made it ubiquitous in the global textile market, from high-end fashion to everyday wear. Dacron, being a specialized type of polyester, might carry a premium over generic polyester materials, especially in niche applications where its specific properties are required.

Applications

Dacron Applications

Specific Uses in Various Industries

Dacron’s unique properties make it suitable for a wide range of applications. In the marine industry, it’s used for sails due to its strength and resistance to water and UV radiation. The medical field utilizes Dacron in vascular grafts and other implants, benefiting from its durability and biocompatibility. Additionally, it serves as an excellent material for outdoor gear, including tents and sleeping bags, where its lightweight and durable nature are essential.

Polyester Applications

Broad Applications and Innovations

Polyester’s versatility extends far beyond clothing. It’s a key material in the production of home furnishings, such as curtains, carpets, and upholstery, offering aesthetic flexibility along with practical benefits like ease of care and durability. In the automotive industry, polyester fibers reinforce tires and are used in seat belts and airbags. Technological advances have also led to the development of specialized polyester fabrics with added functionalities, such as flame retardancy, antimicrobial properties, and enhanced UV resistance.

Choosing Between Dacron and Polyester

Factors to Consider

When deciding between Dacron and Polyester, consider the specific needs of your application:

- Strength and Durability: Dacron might be preferable for high-stress applications.

- Elasticity and Flexibility: Choose specific types of polyester if elasticity is a key requirement.

- Cost-Effectiveness: General polyester fabrics usually offer a good balance between performance and price.

Expert Recommendations

Insights from Industry Professionals

Industry experts suggest evaluating the end use of the product when choosing between Dacron and Polyester. For outdoor and marine applications, Dacron’s robustness and UV resistance make it the superior choice. For clothing and home furnishings, polyester’s versatility and affordability are highly advantageous. Ultimately, the decision should be based on a careful consideration of the material’s physical properties, environmental impact, and cost, alongside the specific demands

FAQs

What is Dacron used for?

Dacron is predominantly used in applications that require high tensile strength and minimal stretching. This includes sails for boats, various types of threads, batting for quilts, and even in medical devices like heart valve prostheses. Its durability and resistance to wear make it ideal for products that demand long-lasting performance.

How is Polyester different from Dacron?

While Dacron is a specific type of Polyester known for its strength and resistance to stretching, Polyester in a broader sense is used in a wider array of products due to its versatility. This includes clothing, home furnishings like curtains and bed sheets, and industrial materials. Polyester’s adaptability comes from its ability to be engineered in different forms to suit various applications.

Can Dacron and Polyester be recycled?

Yes, both Dacron and Polyester can be recycled, which contributes to reducing the environmental impact of textile waste. Recycling processes transform these fibers into new materials, extending their lifecycle and promoting a more sustainable approach to textile production and consumption.

Is Polyester more durable than Dacron?

Durability between Dacron and Polyester varies depending on the specific application and the way the material is processed. Generally, Dacron is praised for its high tensile strength in applications like sailing equipment, while Polyester’s durability is recognized in clothing and furnishings, where it can withstand frequent use and washing.

Conclusion

The journey through the world of synthetic fibers reveals a landscape where Dacron and Polyester play pivotal roles. Their emergence as staples in the textile industry reflects a broader trend towards materials that offer both performance and practicality. As we’ve explored, each has its niche, with Dacron excelling in applications requiring robustness and Polyester shining in its adaptability and widespread use.

Understanding the nuanced differences between Dacron and Polyester enhances our appreciation for the advancements in textile technology. These materials, through their diverse applications and contributions to durability and efficiency, underscore the innovative spirit of the fabric industry. As we continue to value the qualities that each fiber brings to the table, their significance in daily life and specialized fields alike remains undisputed, weaving together the fabric of our modern world.