Sterilization processes play a pivotal role in ensuring the safety and efficacy of products in the food safety and pharmaceutical industries. These procedures are designed to eliminate or deactivate all forms of life and other biological agents from a product or surface. The precision and effectiveness of these processes are critical, with two key parameters standing out: the D value and the Z value. Each serves as a cornerstone in the establishment of sterilization standards, yet their roles and implications differ significantly.

The D value, or Decimal Reduction Time, refers to the time required at a specific temperature to reduce the microbial population by 90% or one log10. In contrast, the Z value represents the temperature change needed to achieve a tenfold change in the D value. These metrics are indispensable in designing and evaluating sterilization processes, offering insights into the thermal resistance of microorganisms and the efficiency of heat treatment methods.

Understanding the difference between the D value and the Z value is crucial for professionals in fields where sterilization is a concern. These values not only influence the choice of sterilization parameters but also impact the overall safety, quality, and shelf life of the treated products. By tailoring sterilization processes based on the D and Z values, industries can achieve optimal results, ensuring products are safe for consumption or use while maintaining their integrity and effectiveness.

Basics of Sterilization

Sterilization is a process essential in many industries, notably in healthcare, food production, and pharmaceuticals. Its primary goal is to eliminate all forms of life and other biological agents from a particular environment or product. This includes bacteria, viruses, fungi, and spore forms, which are known for their resilience and ability to cause contamination. The importance of sterilization cannot be overstated; it is critical for ensuring the safety and efficacy of medical devices, maintaining the sterility of surgical instruments, ensuring food safety, and preserving the integrity of pharmaceutical products.

Common Methods

Sterilization methods can be broadly categorized into physical and chemical processes, each with its mechanisms and applications.

- Physical sterilization methods include:

- Heat sterilization, which uses high temperatures to destroy microorganisms.

- Filtration, which physically removes microbes from liquids or gases.

- Radiation, utilizing gamma rays, electron beams, or X-rays to sterilize items.

- Chemical sterilization methods involve:

- The use of ethylene oxide, a gas that can penetrate packaging and products to kill microorganisms.

- Liquid chemical sterilants that are effective for items that cannot withstand heat sterilization.

Heat sterilization is particularly noteworthy due to its widespread use and effectiveness. It can be further divided into moist heat (such as autoclaving) and dry heat methods. Moist heat sterilization is effective because water conducts heat better than air, allowing for quicker and more efficient sterilization at lower temperatures. Dry heat sterilization, on the other hand, is used for materials that might be damaged by moist heat or for materials that are impenetrable to moisture.

Key Parameters

When discussing sterilization, two critical parameters often come into focus: the D value and the Z value. Understanding these parameters is crucial for designing effective sterilization processes.

D Value Explained

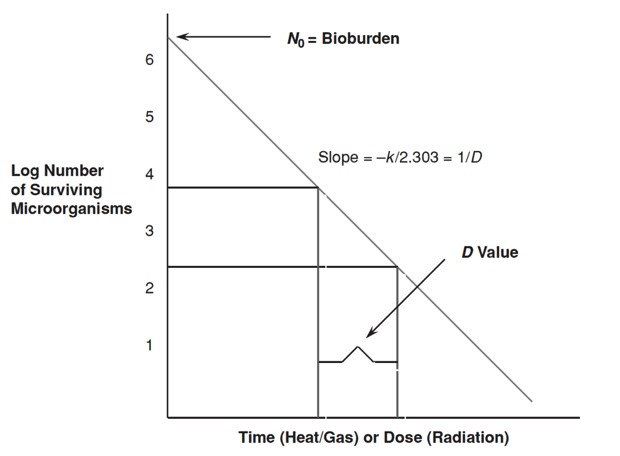

The D value, or Decimal Reduction Time, is a measure of the time required to reduce a microbial population by 90% at a specific temperature. It is a critical indicator of microbial resistance to sterilization processes. The D value allows for the comparison of the resistance of different microorganisms to various sterilization methods. Calculating the D value involves:

- Exposing a microbial population to a sterilization process.

- Measuring the time it takes to achieve a one-log reduction in the population.

This parameter is significant because it provides a basis for designing sterilization cycles that are capable of effectively reducing the microbial load to safe levels.

Z Value Unpacked

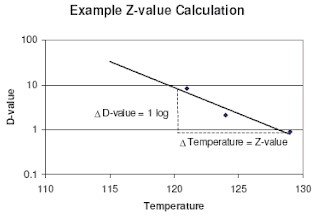

The Z value represents the temperature change required to achieve a tenfold change in the D value. In simpler terms, it indicates how much the temperature needs to increase to make the sterilization process ten times faster. The Z value is a measure of the thermal resistance of a microorganism and is calculated by:

- Determining the D values at different temperatures.

- Using these values to calculate the slope of the line in a semi-logarithmic plot of D value versus temperature.

The Z value is crucial for adjusting sterilization processes in response to variations in microbial resistance or changes in sterilization conditions.

D Value Detailed

Calculation

Calculating the D value involves several steps and considerations. It’s important to understand that the D value varies based on the type of microorganism, the sterilization method used, and the specific conditions of the sterilization process, such as temperature and humidity. The steps include:

- Preparing a microbial culture of known concentration.

- Exposing this culture to the sterilization process.

- Sampling the culture at regular intervals.

- Determining the time at which the population has been reduced by 90%.

Factors influencing the D value include the type of microorganism, the presence of protective mechanisms within the microorganisms (such as spores), and the environmental conditions during sterilization.

Applications

The D value is applied across various industries to ensure the efficacy of sterilization processes. For instance:

- In the food industry, it helps in designing pasteurization and canning processes to ensure food safety without compromising nutritional and sensory qualities.

- In healthcare, it guides the sterilization of medical devices and surgical instruments, ensuring they are safe for use.

- In pharmaceuticals, it assists in the development of sterilization procedures for medications and vaccines, ensuring they remain effective and free of microbial contamination.

Importance

The significance of the D value in effective sterilization cannot be understated. It directly relates to the safety standards required in industries where sterility is a non-negotiable aspect of product quality and safety. The D value provides a scientific basis for sterilization protocols, ensuring that they are both efficient and effective in eliminating harmful microorganisms. By understanding and applying the D value, industries can safeguard against the risk of contamination, thereby protecting consumers and patients alike.

Z Value In-depth

Understanding the Z value is crucial for any industry that relies on thermal sterilization processes. This parameter offers a deep dive into the thermal resistance of microorganisms, providing insights necessary for optimizing sterilization practices.

Calculation

The formula for calculating the Z value involves understanding the relationship between temperature changes and their effect on the D value. The Z value is calculated using the following steps:

- Measure the D value at at least two different temperatures.

- Plot these D values on a semi-logarithmic graph against temperature.

- Calculate the slope of the line, which directly gives the Z value.

The key variables in this calculation include the D values at different temperatures and the temperature difference between these measurements. The formula encapsulates how sensitive a microorganism’s death rate is to temperature changes, offering a numerical expression that’s invaluable in process optimization.

Applications

The Z value’s role in process optimization cannot be overstated. It helps industries adjust sterilization temperatures to improve efficiency without compromising product safety. For instance:

- In the food industry, it informs adjustments in cooking and pasteurization temperatures to ensure microbial safety while retaining food quality.

- In pharmaceuticals, it assists in optimizing the sterilization of products sensitive to heat, ensuring they are safe and effective for use.

Importance

The importance of the Z value extends to its impact on thermal processing efficiency and product safety. A precise understanding of the Z value allows for:

- More efficient sterilization cycles, reducing energy consumption and processing time.

- Enhanced safety protocols, ensuring that products meet rigorous safety standards.

Comparing D and Z Values

Understanding the differences and interrelations between the D value and Z value is essential for effective sterilization.

Key Differences

- The D value measures the time needed to reduce a microbial population by 90% at a specific temperature.

- The Z value reflects the temperature change needed to achieve a tenfold change in the D value.

These differences highlight the distinct roles each parameter plays in sterilization.

Interrelation

The D value and Z value are interconnected in that the Z value can significantly affect the calculation and application of the D value. For instance:

- A low Z value indicates that small changes in temperature can greatly accelerate microbial death rates, potentially allowing lower temperatures to be used in sterilization processes.

Decision Making

When it comes to decision making in industry settings, understanding both D and Z values is critical. Guidelines for selecting sterilization parameters include:

- Assessing the thermal resistance of target microorganisms through the Z value to choose an effective sterilization temperature.

- Using the D value to determine the duration of the sterilization process at the chosen temperature.

Practical Applications

Case Studies

Real-world applications of D and Z values highlight their significance across various sectors:

- Food Industry: A canned food manufacturer uses D and Z values to adjust processing times and temperatures, ensuring the destruction of Clostridium botulinum spores while preserving food quality.

- Healthcare: A hospital sterilizes surgical instruments by applying specific D and Z values to eliminate resistant bacteria, ensuring patient safety.

Challenges and Solutions

Optimizing D and Z values presents challenges, including:

- Variability in microbial resistance: Different strains of microorganisms can exhibit varied resistance, complicating the establishment of universal sterilization parameters.

Solutions include:

- Conducting thorough microbial assessments to tailor sterilization processes to the specific resistance profiles of microorganisms present.

Frequently Asked Questions

What is the D value in sterilization?

The D value, or Decimal Reduction Time, is a critical parameter in sterilization that measures the time required to reduce the viable microbial population by 90% at a specific temperature. It provides a quantifiable measure of a microorganism’s resistance to a sterilization process, serving as a benchmark for ensuring the efficacy of sterilization methods.

How is the Z value used in sterilization?

The Z value in sterilization indicates the temperature change necessary to achieve a tenfold change in the D value. It is a key factor in assessing the thermal resistance of microorganisms and is crucial for optimizing sterilization processes. By understanding the Z value, industries can adjust temperature settings to enhance the effectiveness of heat treatments, ensuring thorough sterilization.

Why are D and Z values important in food safety?

D and Z values are essential in food safety as they guide the design and validation of thermal processing methods to ensure the destruction of pathogenic microorganisms. They help in determining the appropriate sterilization conditions needed to achieve product safety without compromising quality, ultimately protecting consumers from foodborne illnesses.

Can D and Z values vary between microorganisms?

Yes, D and Z values can significantly vary between different microorganisms due to variations in their thermal resistance. Each microorganism has unique characteristics that affect its susceptibility to heat, making it necessary to determine specific D and Z values for the target pathogens in a given sterilization process.

Conclusion

The intricacies of sterilization processes underscore the vital roles of D and Z values in achieving safety and efficacy in products. These parameters are not just numbers but are critical tools that guide industries in designing, validating, and optimizing sterilization methods. By understanding and applying these values, professionals can ensure that their products meet the highest standards of safety and quality.

In conclusion, the differentiation between the D value and Z value is more than a technicality; it is a fundamental aspect of product safety and efficiency. As industries continue to evolve and face new challenges in sterilization, the importance of these values will only grow. Professionals equipped with this knowledge will be better prepared to make informed decisions, ensuring the well-being of consumers and the success of their products in the market.