Electrochemical reactions are central to various scientific and industrial processes, and understanding the dynamics of these reactions, particularly polarization, is critical. Polarization, which occurs in two primary forms—anodic and cathodic—plays a significant role in the corrosion behavior of metals. Each type of polarization has distinct characteristics and implications that are vital for material engineers and corrosion scientists.

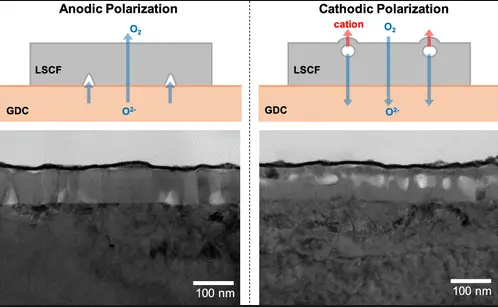

Anodic polarization involves the oxidation of the metal surface, leading to material loss and degradation, whereas cathodic polarization, by contrast, involves a reduction reaction that can sometimes protect the metal from further corrosion. The fundamental difference lies in the electrochemical mechanisms driving each process, making it crucial to distinguish between them to effectively manage corrosion and material longevity.

The significance of these processes extends beyond academic interest, influencing the practical choices in material design, protective coatings, and corrosion management strategies across industries. Recognizing the distinct behaviors of anodic and cathodic polarization helps in selecting appropriate materials and methods for preventing corrosion, thus extending the life of components in harsh environments.

Anodic Polarization

Definition and Basics

Anodic polarization refers to the electrochemical process where an anode in a galvanic cell undergoes increased oxidation. This process results in the metal at the anode losing electrons more rapidly than under normal conditions. Anodic polarization is a key factor in the corrosion and deterioration of metals, making it a critical area of study in materials science and engineering.

Mechanisms and Behavior

The primary mechanism behind anodic polarization involves the movement of electrons from the anode to the cathode within an electrolytic solution. This electron flow leads to the oxidation of the metal at the anode, forming metal ions that can dissolve into the surrounding environment. The rate at which this occurs can be influenced by the electrochemical potential and the environmental conditions.

- Electron flow: Electrons move from high to low potential.

- Oxidation: Metal at the anode loses electrons and oxidizes.

- Ion formation: Oxidized metal forms ions that may dissolve or form compounds.

Key Factors Influencing Anodic Polarization

Several factors can significantly impact the rate and extent of anodic polarization:

- Electrolyte composition: Salts, acids, and bases in the environment can enhance conductivity.

- pH levels: High acidity or alkalinity can accelerate corrosion.

- Temperature: Higher temperatures increase reaction rates.

- Metal type: Different metals have different inherent electrochemical properties.

Examples in Industry In the oil and gas industry, pipelines are often subject to anodic polarization, leading to corrosion-related failures. Similarly, marine structures face constant threats from seawater, a potent electrolyte that accelerates anodic polarization.

Cathodic Polarization

Definition and Fundamentals

Cathodic polarization occurs when the cathode in an electrochemical cell becomes more resistant to reduction. This process is often utilized to protect the metal from corrosion, as it prevents the cathode from absorbing more electrons and undergoing further chemical reactions.

Mechanisms and Behavior

At the cathode, reduction reactions typically involve the gain of electrons by metal ions, which can lead to the deposition of a protective layer on the metal’s surface. This layer can effectively shield the metal from corrosive elements.

- Electron gain: Metal ions at the cathode gain electrons.

- Reduction: The reduction process forms a protective deposit.

- Protection: This deposit shields the metal from further attack.

Influencing Factors

Cathodic polarization is influenced by:

- Current density: Higher currents can enhance protection.

- Electrolyte conductivity: Better conductivity can improve the efficiency of cathodic protection.

- Impurities: Certain impurities can hinder the protective processes.

Industrial Applications Cathodic polarization is widely used for protecting underground storage tanks, ship hulls, and buried pipelines through techniques such as cathodic protection, where sacrificial anodes are employed to undergo corrosion instead of the protected metal.

Comparing Anodic and Cathodic

Similarities Overview

Both anodic and cathodic polarization are integral to understanding corrosion and protection mechanisms in metals. They both involve essential electrochemical reactions and are influenced by similar environmental factors.

Detailed Differences

While anodic polarization often leads to corrosion, cathodic polarization generally protects against it. Anodic involves oxidation, and cathodic involves reduction.

Table Summary: Side-by-Side

| Feature | Anodic Polarization | Cathodic Polarization |

|---|---|---|

| Primary Reaction | Oxidation | Reduction |

| Typical Outcome | Corrosion, metal loss | Protection, metal preservation |

| Influential Factors | Electrolyte, pH, temperature | Current density, electrolyte |

| Industrial Use | Corrosion study, risk assessment | Corrosion prevention, structural protection |

This comparative analysis highlights the contrasting yet complementary roles that anodic and cathodic polarization play in the life and durability of metal structures across various industries.

Impact on Material Selection

Metals and Alloys

The choice of metals and alloys in construction and manufacturing is heavily influenced by their susceptibility to anodic and cathodic polarization. Materials are selected based on their ability to withstand specific environmental conditions without significant degradation. Stainless steel, aluminum, and titanium are common choices for their resistance to corrosion, directly linked to their behavior under polarizing conditions.

Influence on Durability

Durability of materials in corrosive environments hinges on their polarization characteristics. Metals that exhibit favorable cathodic polarization are preferred for environments where they are prone to aggressive agents, as this can significantly extend the lifetime of the material through reduced corrosion rates.

Selection Criteria Based on Polarization

Selecting materials for a specific application involves evaluating their polarization behavior:

- Corrosion rate: How quickly does the material corrode under anodic conditions?

- Protective potential: Does the material exhibit cathodic properties that can inhibit corrosion?

- Environmental resistance: How does the material behave in different pH levels or temperatures?

Measurement Techniques

Tools and Methods

The assessment of anodic and cathodic polarization requires precise tools and methods:

- Potentiostats: Control the potential of an electrode to study its polarization.

- Galvanostats: Maintain a constant current to observe changes in electrode potential.

- Electrochemical impedance spectroscopy (EIS): Analyzes the impedance of a system over a range of frequencies to determine corrosion rates.

Interpretation of Results

Results from these measurements must be interpreted to provide actionable insights:

- Polarization curves: Graphs that show the relationship between electrode potential and current density.

- Corrosion rates: Calculated from polarization data to predict material lifespan.

- Passivation behavior: Identification of conditions under which materials form protective oxide layers.

Recent Technological Advancements

Advancements in digital imaging and automated data analysis have improved the precision of polarization measurements, enabling more accurate assessments of material performance in corrosive environments.

Case Studies

Case Study 1: Marine Applications

In marine applications, cathodic protection systems are crucial. They employ sacrificial anodes made from zinc or magnesium, which exhibit strong anodic properties and corrode in place of the protected structure.

- Example: Hulls of ships are often fitted with sacrificial anodes to prevent rusting from saltwater exposure.

Case Study 2: Pipeline Protection

Underground and underwater pipelines are protected using impressed current cathodic protection (ICCP) systems. These systems use a more controlled form of cathodic polarization to protect the pipelines over extensive areas.

- Example: ICCP systems are used to protect oil pipelines across continents from corrosion that could lead to environmental disasters.

Insights from Real-World Data

Data collected from these case studies show that appropriate material selection and polarization management can reduce maintenance costs and extend the operational life of industrial assets.

Challenges and Solutions

Common Challenges in Managing Polarization

Managing anodic and cathodic polarization presents several challenges:

- Complex environments: Fluctuating environmental conditions can affect polarization behavior unpredictably.

- Material limitations: Not all materials can withstand necessary modifications to improve polarization properties.

Innovative Solutions and Future Directions

The future of polarization management lies in developing new materials and technologies:

- Nano-coatings: Using nanotechnology to develop coatings that can provide superior protection against polarization.

- Smart monitoring systems: Integrating sensors that can continuously monitor and adjust cathodic protection systems to optimize performance.

Frequently Asked Questions

What is Anodic Polarization?

Anodic polarization refers to the process where an increase in potential causes an increase in the oxidation rate of the anode. This phenomenon typically leads to increased corrosion, particularly in metals exposed to corrosive environments.

How Does Cathodic Polarization Protect Metals?

Cathodic polarization reduces the corrosion rate of a metal by decreasing its tendency to lose electrons. This protective process is often used in galvanic protection and cathodic protection systems to extend the life of metal structures.

Can Both Types of Polarization Occur Simultaneously?

Yes, both anodic and cathodic polarization can occur simultaneously on different parts of the same metal surface, depending on the environmental conditions and the electrochemical properties of the metal.

What Factors Influence Anodic and Cathodic Polarization?

Several factors influence these types of polarization, including the electrolyte composition, temperature, pH of the environment, and the inherent properties of the metal such as its electrochemical potential and conductivity.

Conclusion

The intricate balance between anodic and cathodic polarization forms the cornerstone of modern corrosion science and material engineering. Understanding these processes is essential for designing strategies that mitigate corrosion and enhance the durability of materials. Future trends in research and technological advancements will likely focus on refining these protective techniques to meet the evolving demands of industries.

The knowledge and application of anodic and cathodic polarization not only ensure the longevity of materials but also support sustainable practices in manufacturing and infrastructure development. As industries continue to seek more efficient and cost-effective solutions, the role of detailed understanding in these areas becomes increasingly important.